49

4

1–1 1/4

1–1 1/4

Fuel system

!

Fit the metering diaphragm. Place the gasket on the carburettor

housing followed by the metering dia-

phragm.

Check that the air hole in the cover is

open and screw tight the cover.

Carburettor setting

WARNING!

When test running the engine in connection with adjusting the carburettor, the

clutch and clutch cover must without exception be fitted.

Otherwise there is a risk that the clutch can come loose and cause serious

personal injury.

Function

The purpose of the carburettor is to deliver a combustible mixture of air and fuel to the

cylinder.

The quantity

of this mixture is regulated with the throttle control.

The composition of the mixture

of petrol and air is regulated by means of the adjustable

nozzles ”H” and ”L”.

In order for the engine to provide maximum power at different speeds, run smoothly at

idling speed and respond quickly to the throttle, it is necessary for the nozzles to be

correctly adjusted.

The adjustment of the carburettor can vary somewhat depending on humidity, tempera-

ture and air pressure.

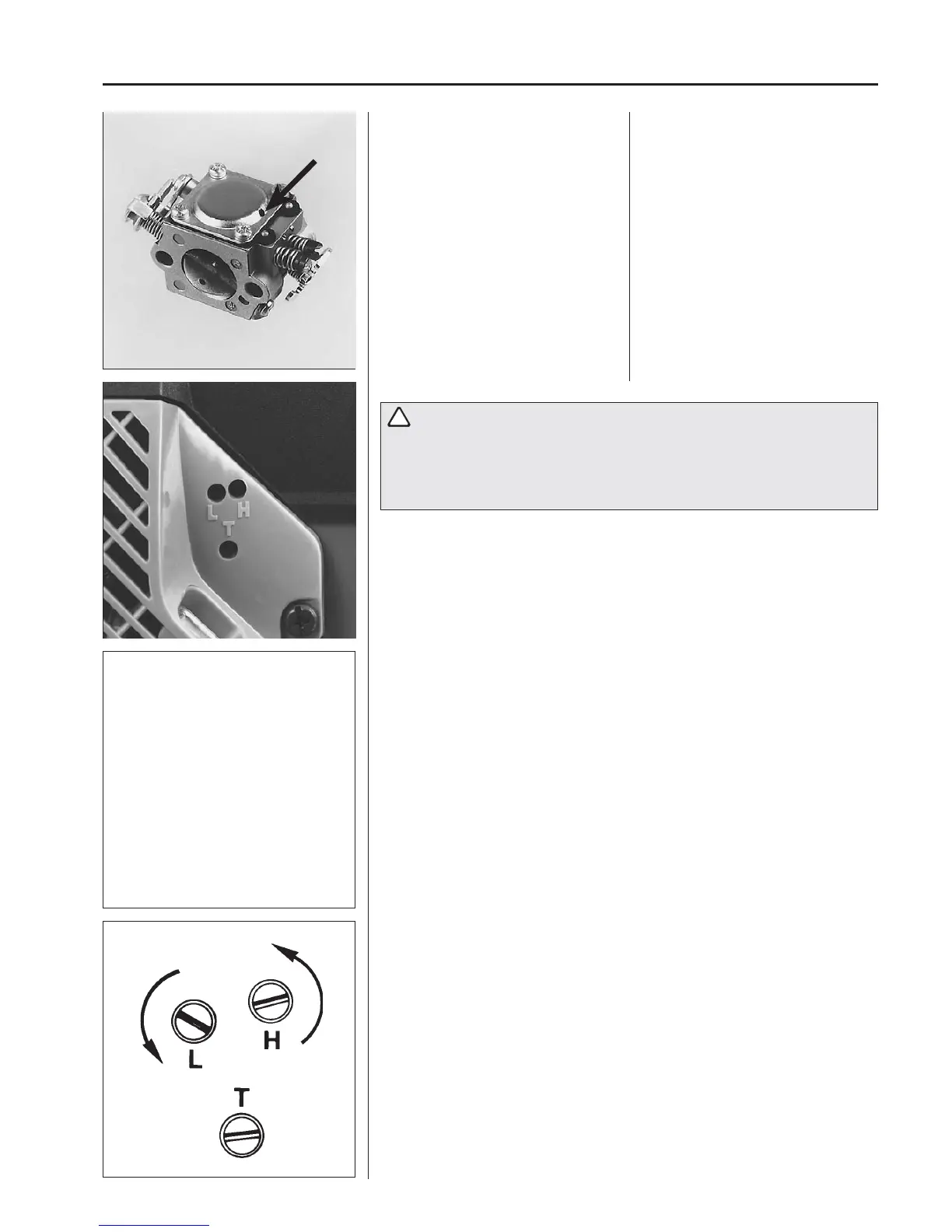

L = Low speed nozzle

H = High speed nozzle

T = Adjuster screw for idling speed

● With the L- and H-nozzles the required fuel quantity is adjusted to the air flow which

the opening of the throttle control permits. If they are screwed clockwise the air/fuel

mixture becomes lean (less fuel), and if they are screwed anti-clockwise the air/fuel

mixture will be rich (more fuel). A

lean

mixture gives

higher

speed and a

rich

mixture

gives

lower

speed.

● The T-screw regulates the throttle control’s position at idling speed. If the T-screw

is screwed clockwise a higher idling speed is obtained, and if it is screwed anti-

clockwise a lower idling speed is obtained.

Basic setting

The carburettor is given a basic setting during test running at the factory. The basic

setting is ”richer” than the optimum setting (the overspeed lies at 600-800 rpm below

the recommended max. overspeed) and should be retained during the first hours the

engine is in operation. After this the carburettor should be fine adjusted. The basic

setting can vary between:

H = 1 to 1 1/4 turn.

L = 1 to 1 1/4 turn.

Fine adjustment

When the engine is ”run in” the carburettor should be adjusted.

● During all adjustments the air filter should be clean and the cylinder cover fitted.

The L-nozzle is adjusted first, followed by the H-nozzle and finally the idling screw T.

Loading...

Loading...