48

502 50 38-01

4

Fuel system

Fit the valve and valve shafts.

NOTE!

Use Locktite on the valve screws.

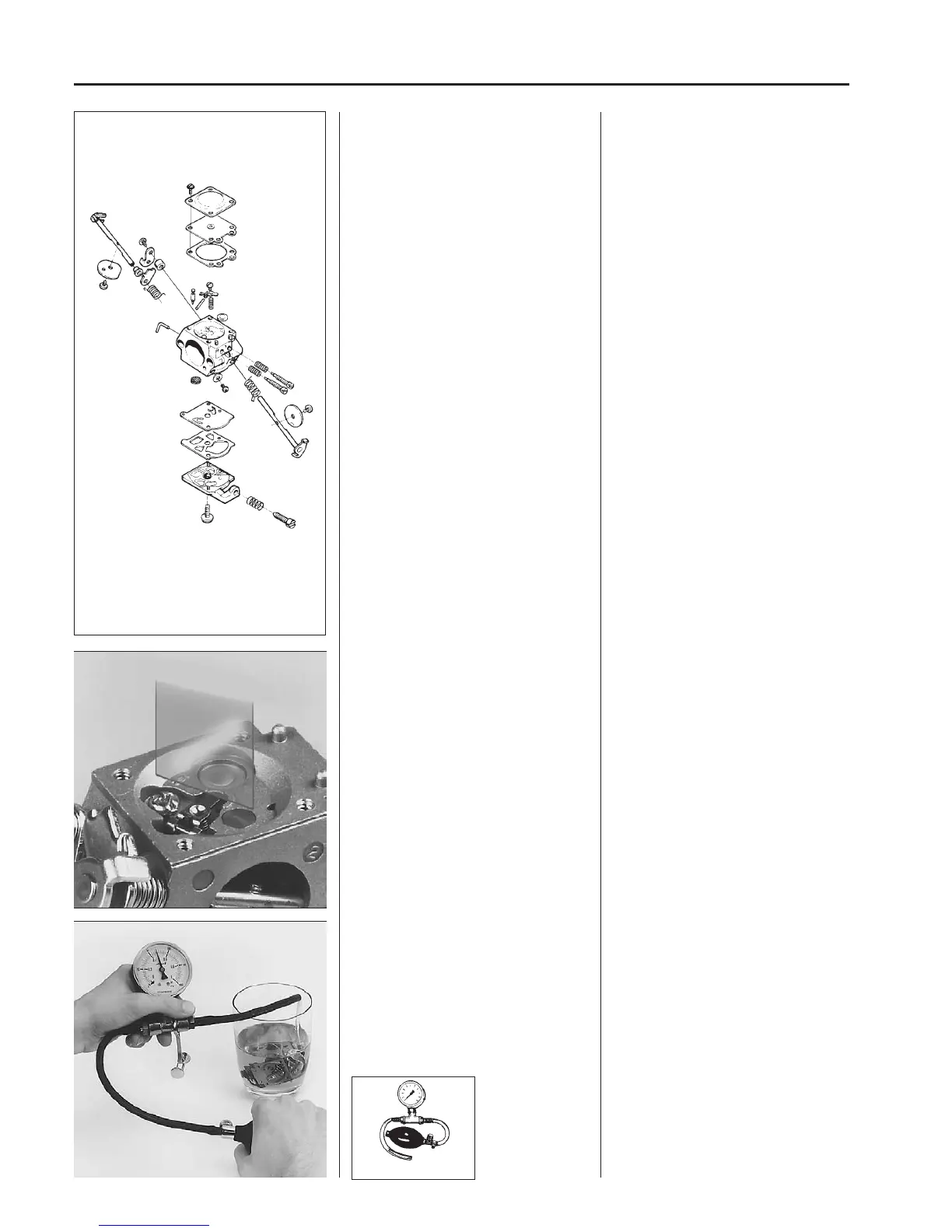

Fit the pump section parts in the reverse

order to dismantling.

Fit the different parts in the metering

section in the reverse order to dismantling.

Check that the carburettor is tight.

No leakage is permissible at 50 kPa

pressure.

● Fit the valve and valve shafts.

NOTE!

Check that the valve and valve shafts are

turned the right way round and that they

seal completely tight in closed position.

Use Locktite on the valve screws.

Tips!

Any number designations on the valve

should be able to be read from outside.

Replace the fuel filter if it is damaged or

cannot be cleaned.

Place the pump diaphragm closest to the

carburettor housing, followed by the

gasket and cover.

Fit the different parts in the metering

section in the reverse order to dismantling.

NOTE!

The H-needle is slightly

shorter

than the

L-needle.

Check that the lever is level:

– With the carburettor housing

(Tillotson).

– With the cast heads (Walbro, Zama).

Too high setting = too much fuel.

Too low setting = too little fuel,

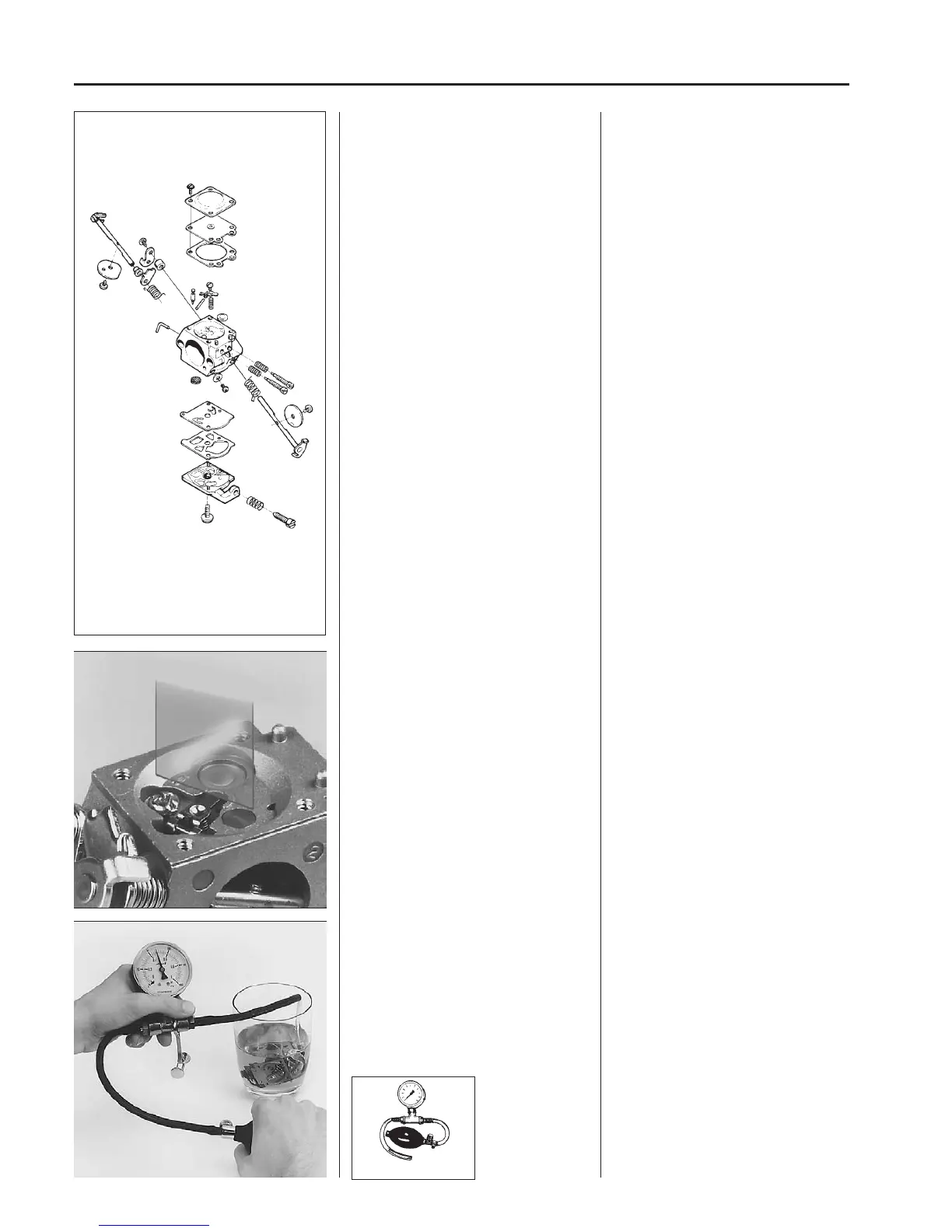

Connect pressure tester No.

502 50 38-01 to the fuel intake in the

carburettor.

Pump up to 50 kPa pressure.

Submerge the carburettor in a basin

containing petrol to more easily discover

leakage.

No leakage is permissible.

Loading...

Loading...