94

Crankshaft and crankcase

8

504 91 40-01

502 50 55-01

Mod. 625/630/670

Mod. 2077/2083

Mod. 2095

505 38 17-09

Mod. 625/630/670

Mod. 2077/2083

Mod. 2095

3 mm

The purpose of the crankshaft in the engine is to

convert the forward and backward movement of

the piston to rotation. In order to do this a stable

construction is required which can withstand high

pressure, torsional and flexural stress, and also

high rotational speeds. The connecting rod is also

exposed to high accelerational and retarding

tensions when it moves between the top and bot-

tom dead centres. This sets special requirements

on the bearings which must withstand rapid load

alternations. In addition the bearing’s roller cage

must withstand high levels of heat and friction.

During service work it is therefore important to

check the roller cage for cracking, wear on the

sides, and discolouring as a result of overheating.

The crankshaft is housed in the crankcase with

heavy-duty ball bearings. In addition to being the

bearing point for the crankshaft, the crankcase also

functions as a pump for fuel/air mixing when this is

”induced” from the carburettor and pressed up in

the cylinder’s combustion chamber. In order not to

interfere with the pump function the crankcase

must be completely tight and there must be no

leakage at the crankshaft or between the crankcase

halves, or between the cylinder and crankcase.

For this reason always replace gaskets and sealing

rings during service work on the crankcase.

Replacement of sealing

ring on magneto side

Mod. 625/630/670

Mod. 2077/2083

Mod. 2095

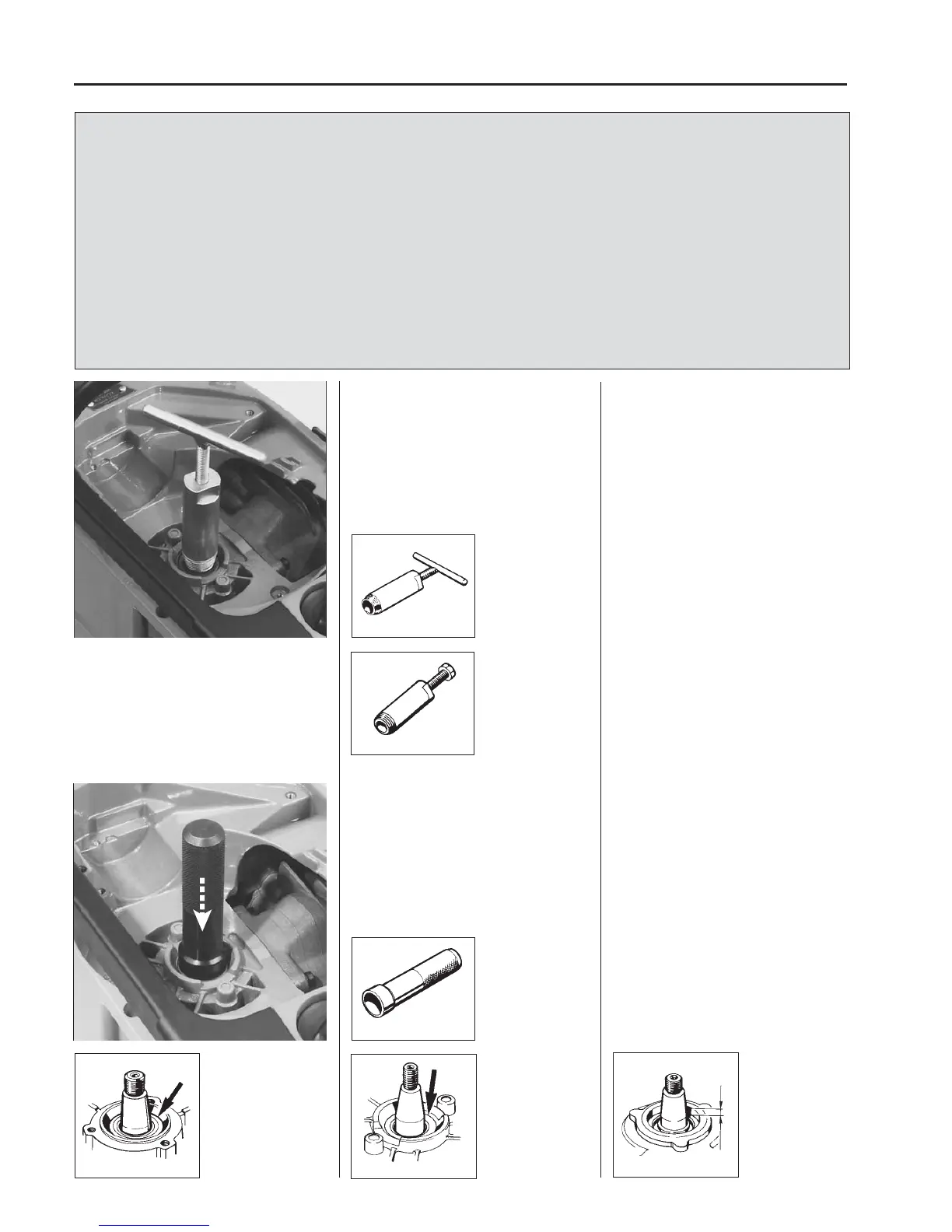

Screw down the sealing ring extractor as

far as possible in the sealing ring and pull

off the sealing ring.

Lubricate the shaft with engine oil and fit

a new sealing ring.

Replacement of sealing

ring on magneto side

Mod. 625/630/670

Mod. 2077/2083

Mod. 2095

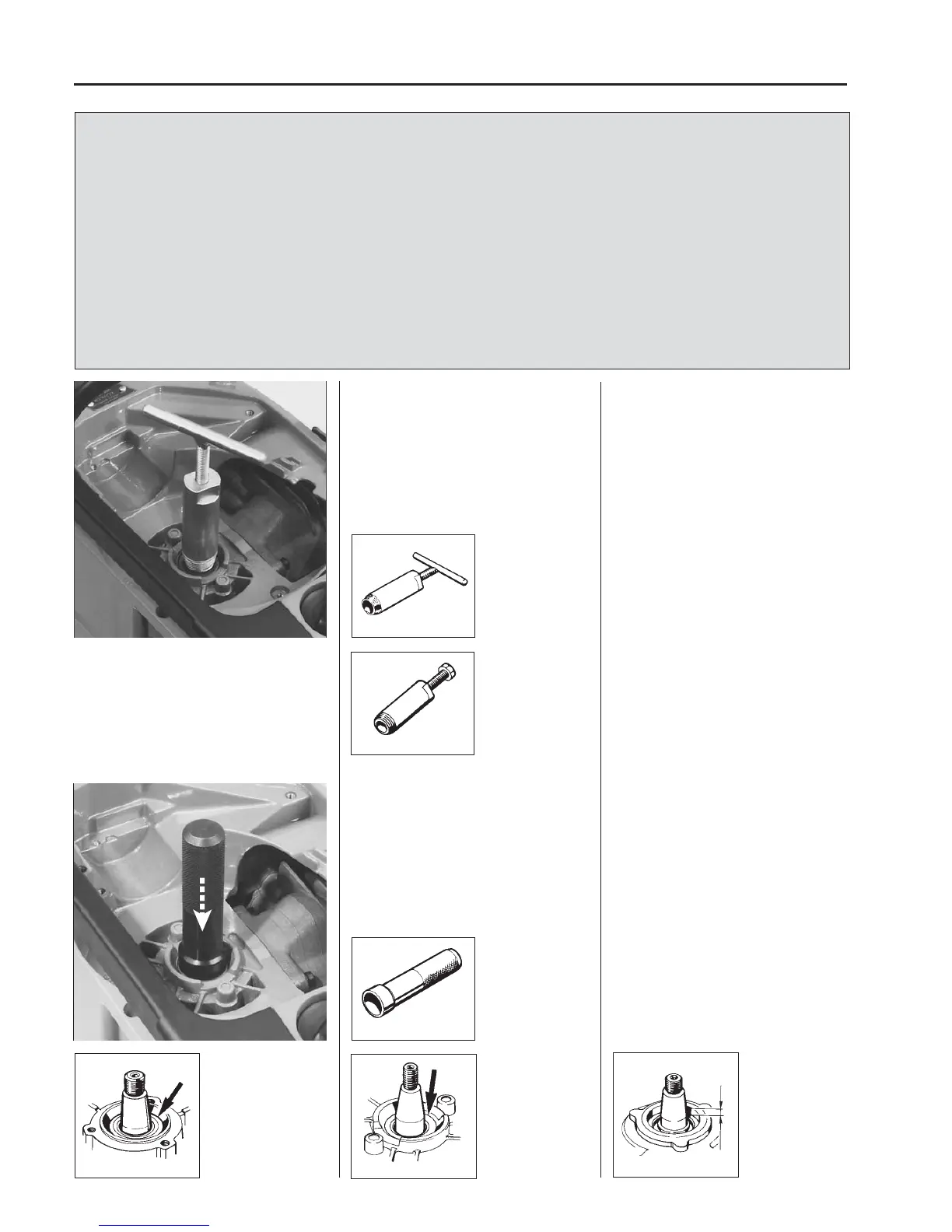

Dismantle all parts on the magneto side

so that the sealing ring becomes access-

ible.

Remove the key for the flywheel by means

of diagonal cutting pliers.

Screw down the sealing ring extractor as

far as possible in the sealing ring and pull

off the sealing ring.

Lubricate the shaft with a few drops of

engine oil and place a new sealing ring in

position with the plate cover turned

outwards.

Press down the sealing ring with a suitable

mandrel to the correct position in the

crankcase.

Fit the other parts in the reverse order to

dismantling.

Loading...

Loading...