CENTRIFUGAL CLUTCH

English – 27

Cleaning and inspection

Clean all components and check the following:

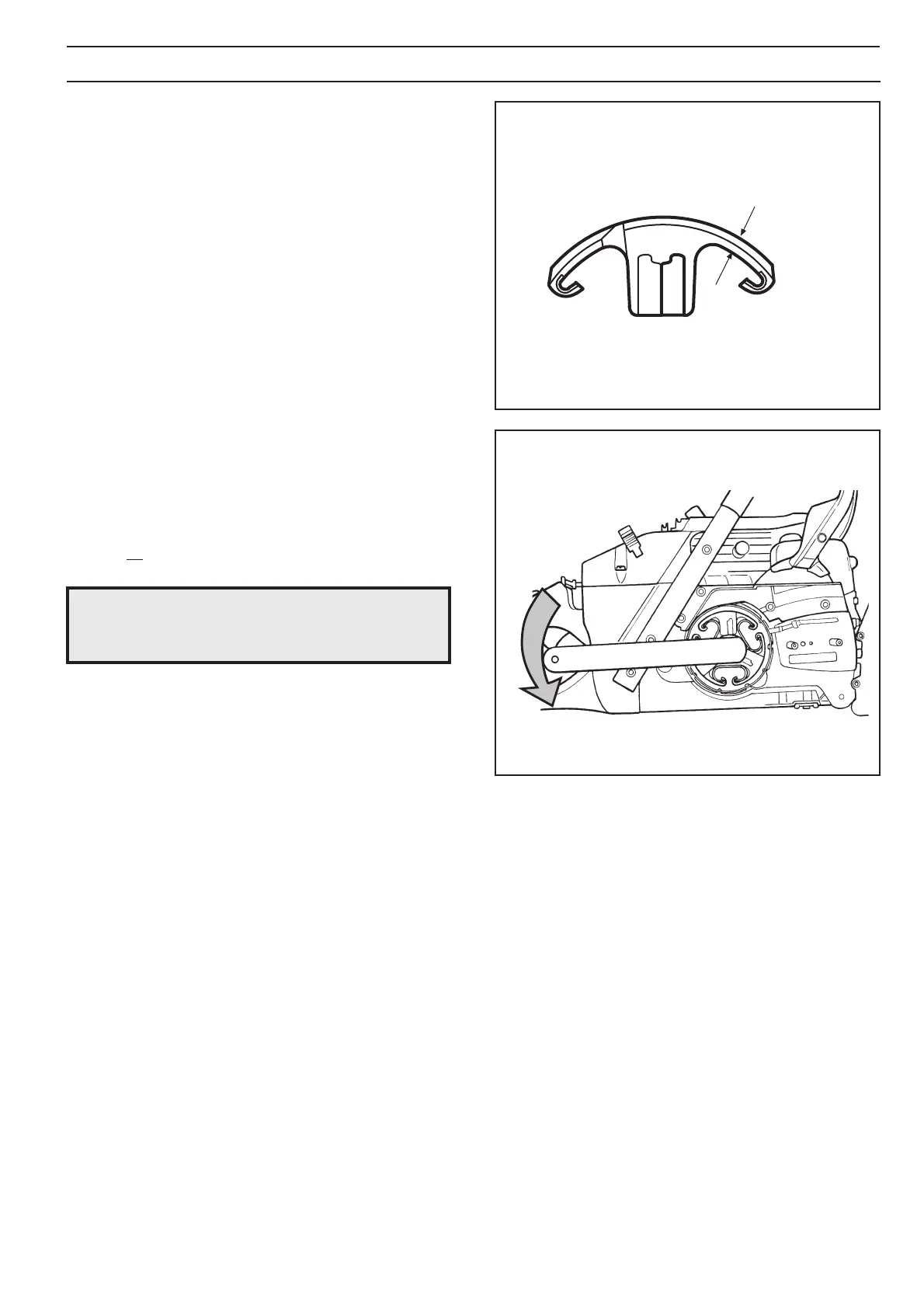

1. The lining thickness on the clutch shoes must not be less

than 3.5 mm at the most worn point. See fig. 5.

To avoid imbalance all the clutch shoes should be replaced

at the same time.

2. There should be no play between the clutch shoes and

the clutch hub.

3. Wear on the chain drive sprocket.

4. The needle bearing should be in good condition and the

journal surface on the crankshaft undamaged.

5. The friction surface on the clutch drum should be intact

and the bearing surface undamaged.

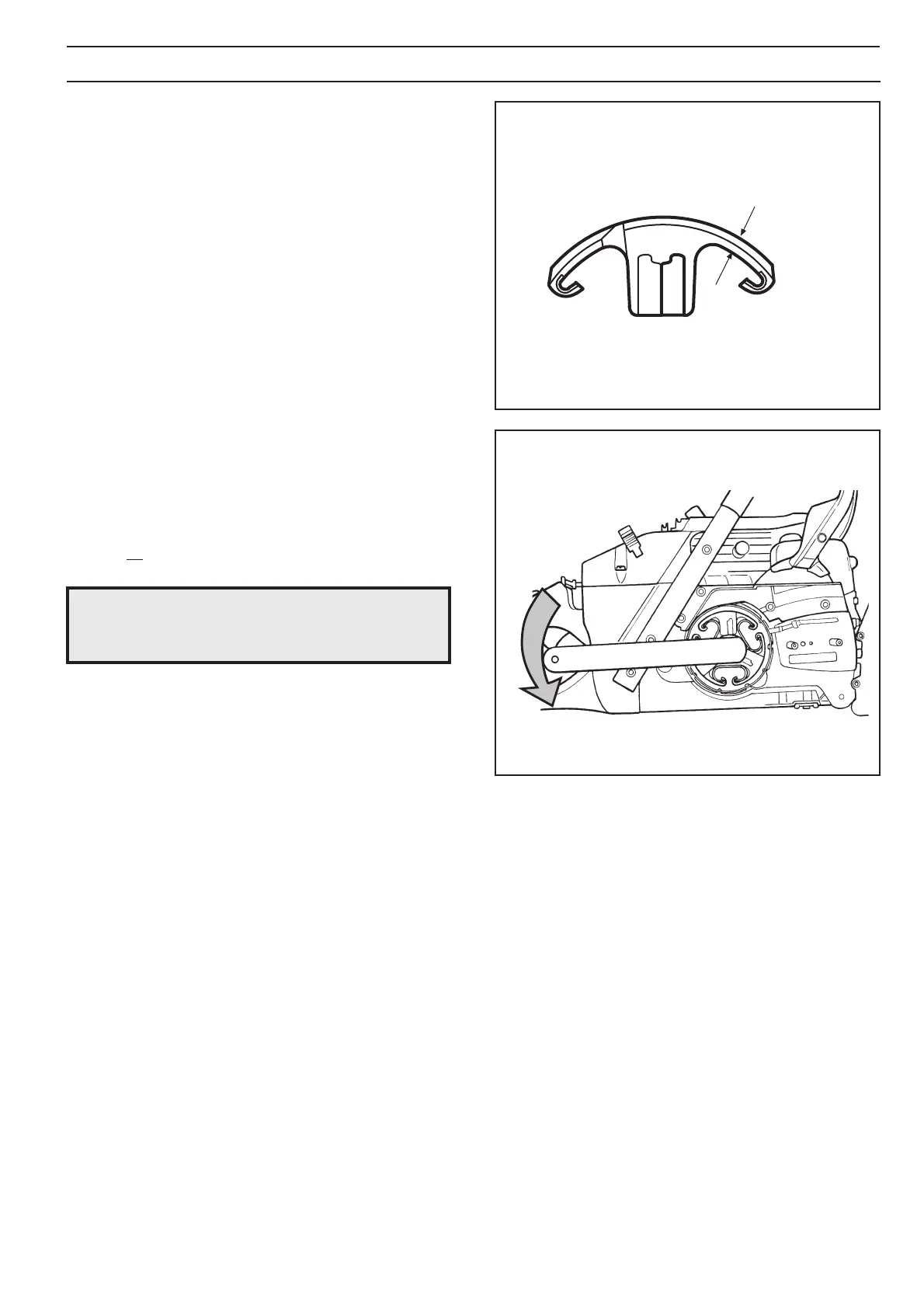

When assembling the centrifugal clutch the chain brake must

be in the off position.

Assembly

Fig. 5

Fig. 6

NOTE!

The clutch springs must not opened more

than is necessary. Risk of deformation.

1. Fit the clutch shoes on the hub and fit the springs with

circlip pliers. See fig. 4.

2. Fit the clutch hub on the crankshaft and tighten with the

clutch tool. Note – left-hand thread!

See fig. 6.

3. Remove the piston stop and fit the spark plug and put on

the ignition cable.

4. Grease in the needle bearing before fitting. Fit the clutch

drum (C) with needle bearing (D) and chain drive sprocket

(E). See fig. 2 page 24.

5. Fit the washer and locking ring (B). See fig. 2 page 24.

6. Fit the cylinder cover, chain and bar. See Operator Guide.

min 3.5 mm

Loading...

Loading...