48 – English

CRANKCASE and CRANKSHAFT

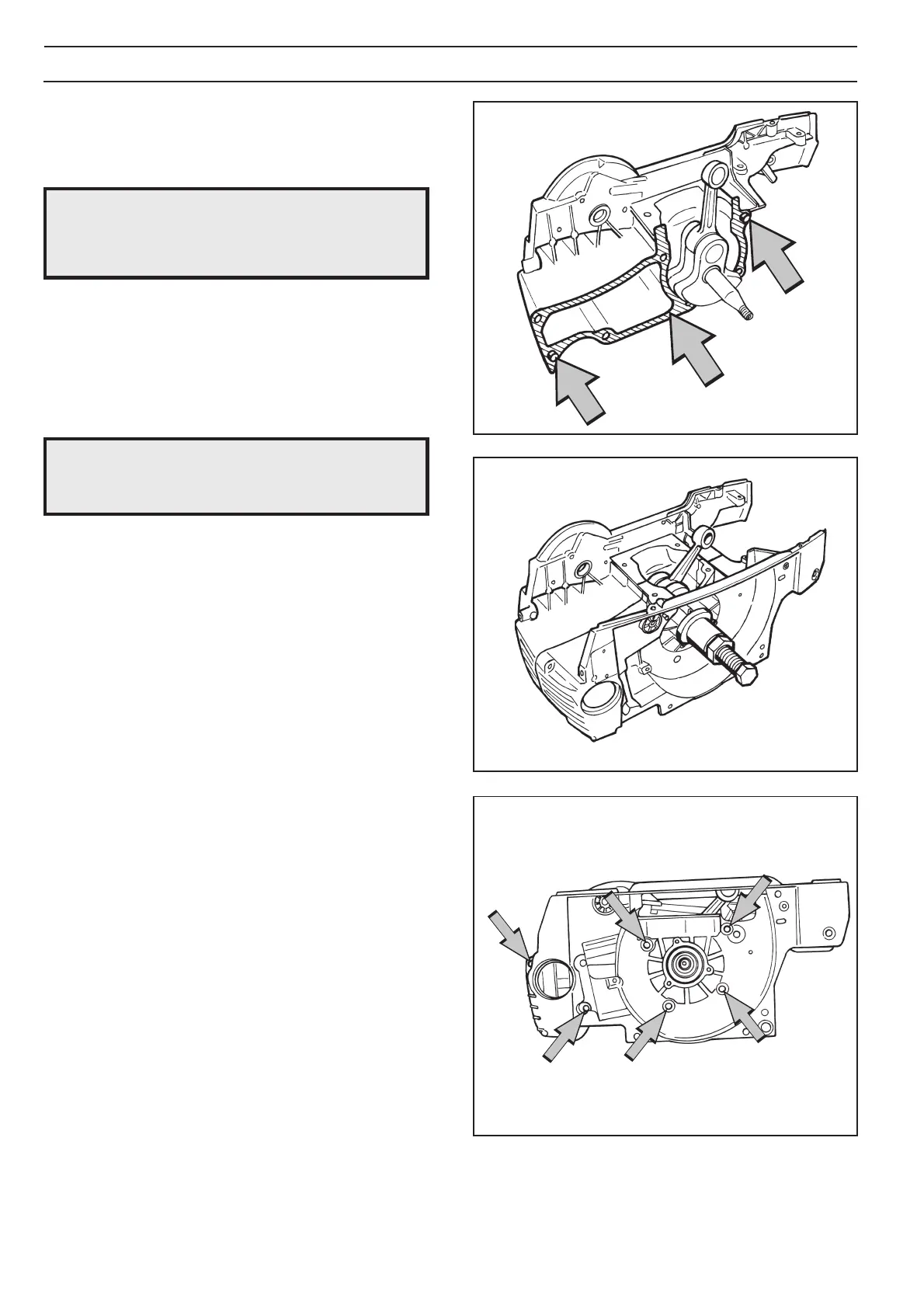

4. Place the guide pegs in the clutch side’s crankcase half,

and grease in and insert the gasket. See fig. 12.

Fig. 12

Fig. 13

Fig. 14

NOTE!

Continuing to pull with the assembly tool

after the gasket is clamped will damage the

crankshaft.

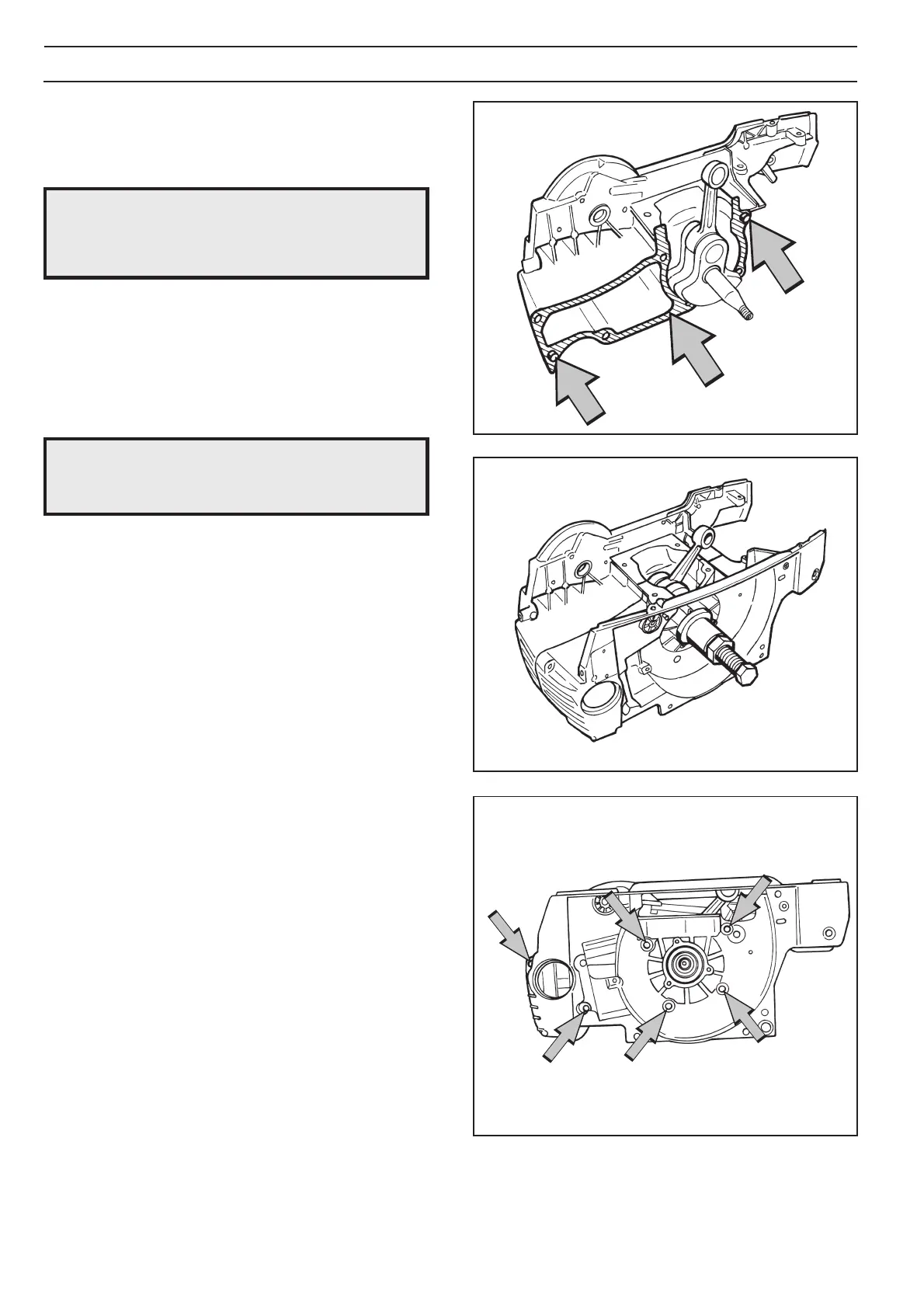

5. Use tool 502 50 30-17 and pull on the flywheel side’s

crankcase half. Pull until the gasket is clamped

between the crankcase halves. See fig. 13.

6. Fit the six bolts. Tighten them alternately. Tighten them

finally to 8 Nm. See fig. 14.

NOTE!

Make sure that excess gasket material does

not fall into the crankcase.

9. Assemble the following parts:

A. Tank unit. See page 38.

B. Piston and cylinder. See page 41.

C. Muffler. See page 17.

D. Carburettor. See page 35.

E. Lubrication system. See page 29.

F. Centrifugal clutch. See page 27.

G. Electrical system. See page 22.

H. Starter. See page 20.

I. Chain and bar. See the Operator Guide.

10.If a new crankshaft is fitted the chainsaw should be

run-in for 3-4 hours with the carburettor set to its basic

settings (H=1/4 and L=1/4 turn). See adjustment of the

carburettor on page 34 and 35.

7. Cut off the gasket at the level of the cylinder’s seating

plane.

8. Fit the carburettor space bottom with the four bolts.

Tighten the bolts to 5 Nm.

Loading...

Loading...