Operating Instructions | KBL Tower space 2000

38

9. Maintenance and cleaning

Regular maintenance is required for the safe opera-

tion of the tanning device and has to be documented.

Cleaning is to be performed when necessary.

• Maintenance work may only be carried out by

authorized, trained and qualified staff.

• Before carrying out any maintenance work, the tan-

ning device must be disconnected from the mains

voltage.

DANGER

Live parts

Risk of fatal injury due to electric shock

when touching live parts.

• Disconnect from mains and secure

against reconnection!

• USE ONLY ORIGINAL SPARE PARTS.

• Replace illuminants and filters only with ones

which are characterized on the device.

9.1 Instructions for cleaning

and care

GENERAL

Before starting to clean the tanning device, take off

any rings, bracelets, watches, etc. that you might be

wearing in order to avoid scratching the surfaces.

Cleaning fluid must not run into the appliance.

TUBES

To preserve the tanning power, we recommend

cleaning the tubes and UV lamps with warm water

and a chamois after approx. 200 hours of operation.

ACRYLIC PANES

For cleaning the acrylic panes, use the special

cleansing agent and disinfectant “megaClean plus”

supplied by KBL for cleaning the acrylic parts and

handles, and dilute it according to manufacturer

information.

VARNISHED AND PLASTIC PARTS

To clean the varnished and plastic surfaces, use a

damp soapy cloth.

Do not clean the big plastic parts with a dry cloth.

This might scratch the surfaces!

To clean the PMMA plastic surfaces of the door

and the mirror plate of the floor, proceed as follows:

Use a damp chamois and spray “megaClean plus“

onto it sparingly. Then wipe the surfaces clean.

NEVER CLEAN WITH A DRY CLOTH!

Prevent the corners and edges from getting wet.

CLEANING AGENTS

The surfaces and the acrylic panes must not be

cleaned with concentrated disinfectants or solvents

or other liquids that contain alcohol.

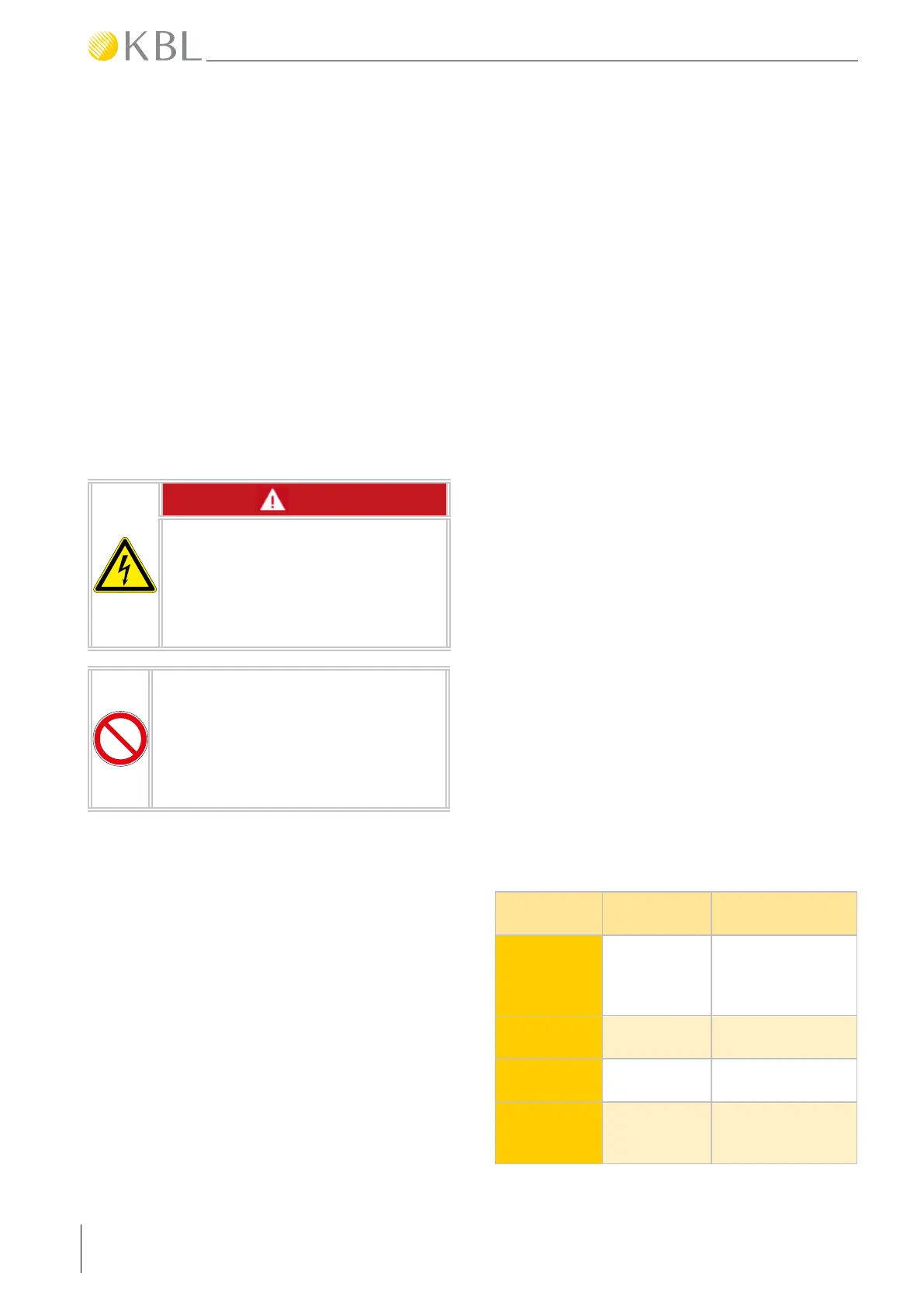

9.2 Maintenance intervals

Component/

wearing part

Cleaning Replacement

Tubes and

starters

Tubes after

approx. 200

operating

hours

After 500 operating

hours

Acrylic panes

When

necessary

When necessary

aquaCool

nozzles

When

necessary

After approx. 1000

operating hours

Colour

filters of unit

lighting

When

necessary

Whenever UV

tubes are replaced

Loading...

Loading...