12 / 1923600E / 0024

English

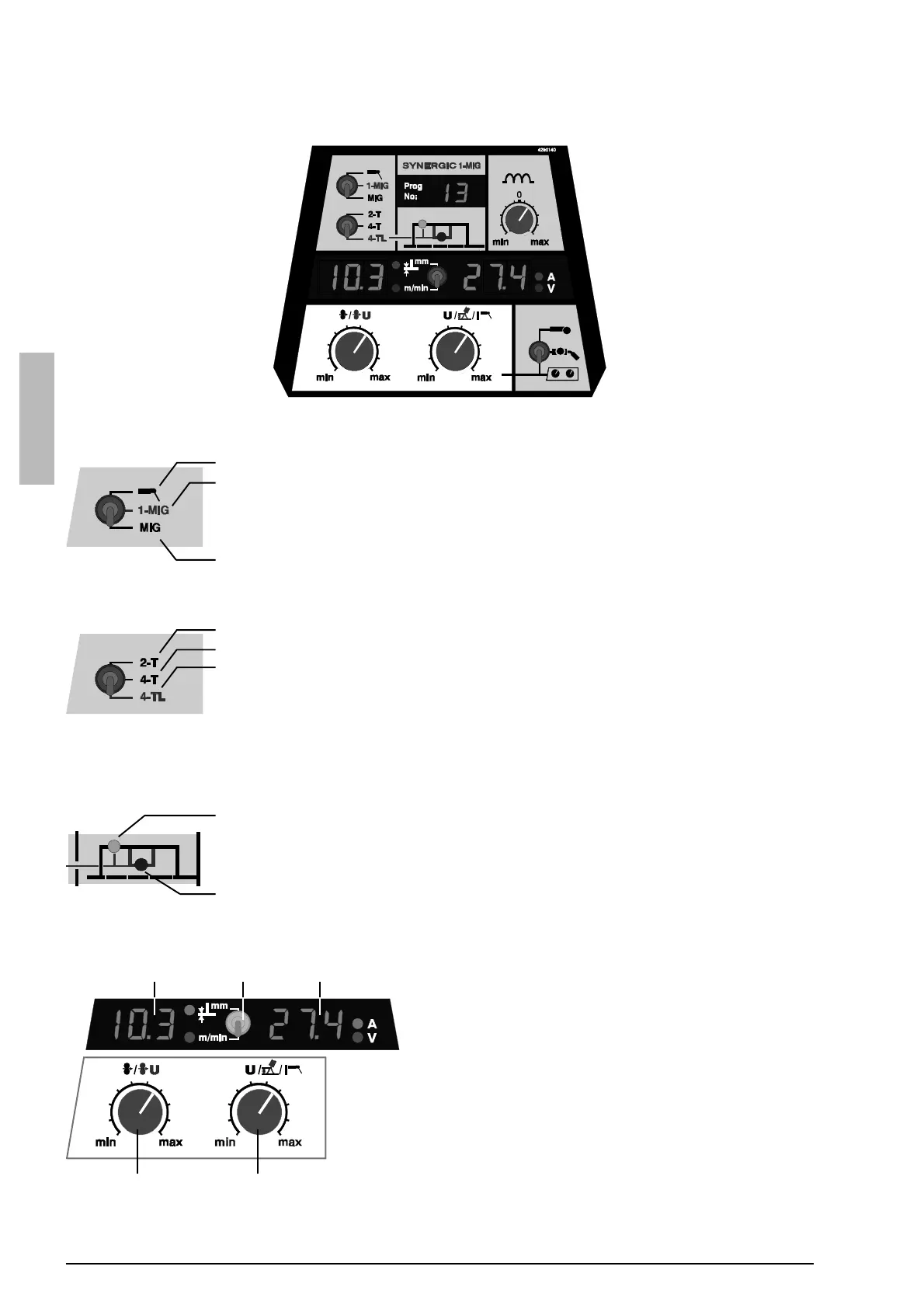

(1) Wire feed speed adjustment by MIG / MAG. Weld-

ing power adjustment by synergic 1-knob MIG.

(2) Welding voltage adjustment by MIG/MAG. Arc length

adjustment by synergic 1-knob MIG. MMA current ad-

justment by MMA welding.

(3) Wire feed speed in m/min, plate thickness display

in mm. Note! you can select the plate thickness dis-

play only by synergic 1-knob MIG.

With the selecting switch (4) is selected which variable

is visible in the display. The plate thickness display is

an informative thickness display for welding plates when

making horizontal vertical fillet welds.

(5) Set value display for welding voltage by MIG and

1-knob MIG, V / MMA current set value display,A.

This display is also used as display for MIG welding

dynamics, -9...0...9.

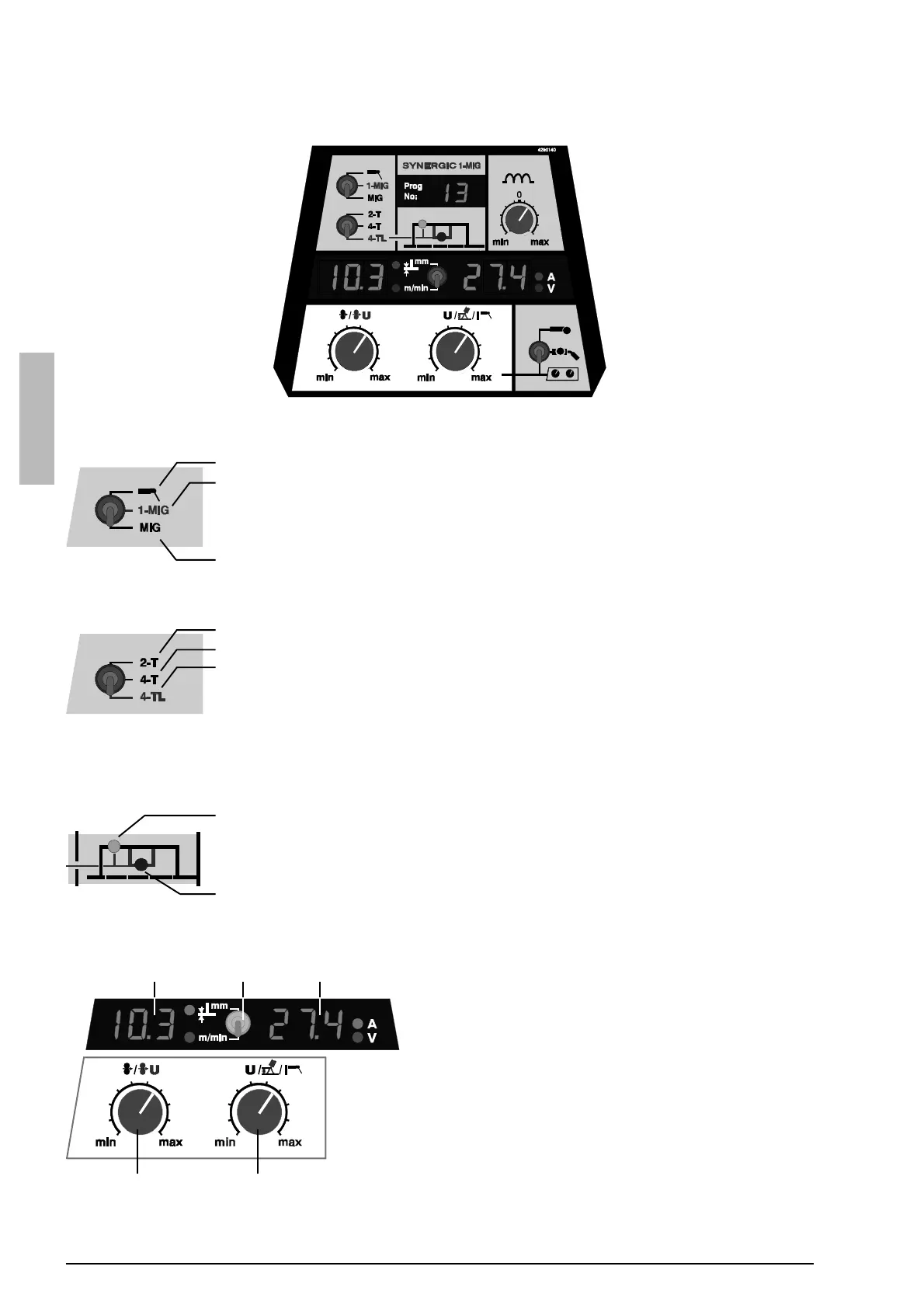

FEED400 FUNCTIONS

Function panel

Selection of welding process

MMA selection, powe source is started for open circuit.

Synergic MIG / MAG welding (1-knob MIG): MIG welding, where wire feed speed de-

fines values of other welding parameters enabling welding´s power level adjustment

from one control knob. Dependence of welding parameters from wire feed speed is

defined by choice of synergic curve for filler wire and gas which are used.

MIG / MAG welding with independent wire feed and voltage controls.

Selection of MIG process

MIG welding with two-sequence start switch procedure, MIG two-sequence

MIG welding with four-sequence start switch procedure, MIG four-sequence

MIG welding with Minilog function, MIG 4-TL. In the 4-TL function the operator can move

during welding by means of the MIG gun´s switch between two different welding powers.

The functions are controlled with long (>0.7 s) and short (<0.7 s) pressings on start switch,

see paragraph MIG Minilog function. The 4-TL procedure is used only in 1-knob MIG

welding.

Signal lamps for Welding / MIG Minilog

LED for welding current. Is continuously illuminated by MIG. Blinking during welding or

when the power source is on open circuit (e.g. MMA welding).

LED for lower Minilog current level. Is illuminated when adjustment values for lower

Minilog current level are visible in displays.

Basic adjustments, basic displays

345

12

Loading...

Loading...