0024 / 1923600E / 9

English

ASSEMBLY OF MIG EQUIPMENT

KEMPOMIGpower source: Read the paragraph INSTALLATION in the operation instructions (1922380E) for

the power source in question.

FEED400 wire feeder unit:

1. Mount the wire feeder onto shaft, which is on top of power source. The shaft must have plastic insulation /

bear bushing.

2. Mount the control cable of the interconnection cable and the welding current cable to connectors on the rear

wall of the FEED 400. Select the MIG gun´s polarity (+ or ) according to welding wire you are using.

3

. If the MIG gun is liquid-cooled, mount the cooling liquid hoses of the interconnection cable through the wire

feeder unit and lock them at their place. If necessary open the side plate of the FEED 400.

4. Mount the MIG gun to EURO connector on the front wall of the FEED400.

Use guide tubes and contact tips according to manufacturer´s operation instructions. Accessories which are

too tight or otherwise unsuitable for the wire type used by you, will cause wire feed disturbances.

5. If you mount the FEED400 onto boom, see that the wire feeder unit´s chassis is without galvanic contact to

boom.

6. Max. wire feed speed

When the unit is delivered the max. wire feed speed is 18m/min, which is enough for the most welding

works. If you need a higher speed, you can increase the max. wire feed speed to 25 m/min by replacing the

gear wheel on motor shaft to a bigger one as well as through change of jumper on the control card. The big

gear wheel (D40) belongs to delivery kit of the FEED400.

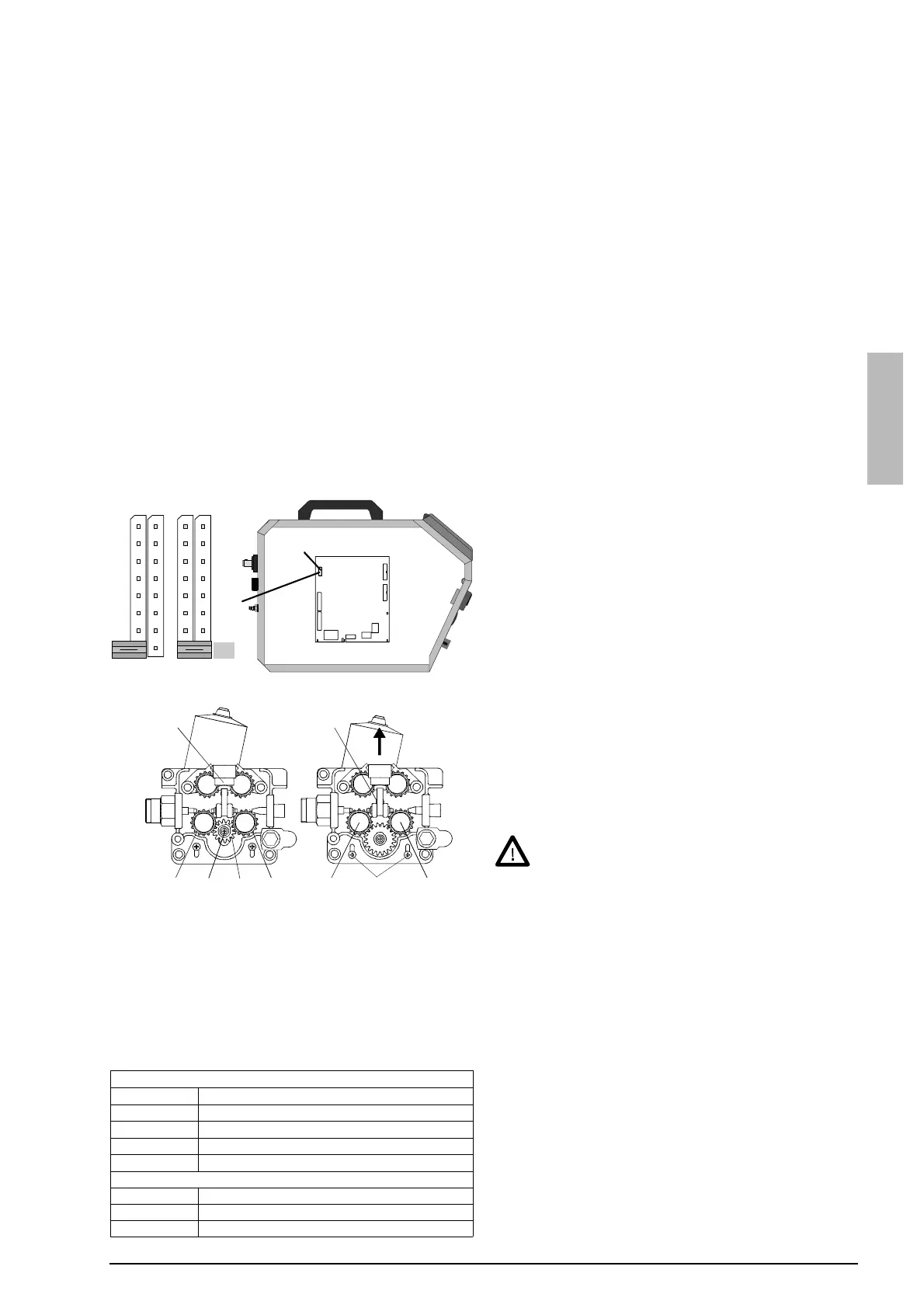

20

21 23 24 21

22 25 22

25

feed rolls

colour filler wire ø mm (inch)

white 0.6 and 0.8 (0.030)

red 0.9/1.0 and 1.2 (0.035, 0.045 and 0.052)

yellow 1.4, 1.6 and 2.0 (1/16 and 5/64)

black 2.4 (3/32)

guide tubes

colour filler wire ø mm (inch)

orange 0.6-1.6 (0.024-1/16)

blue over 1.6 (over 1/16)

When necessary speed is changed according to

following:

Open side plate and move JUMPER BLOCK´s first

coding piece on control card A001 to point 25m/min.

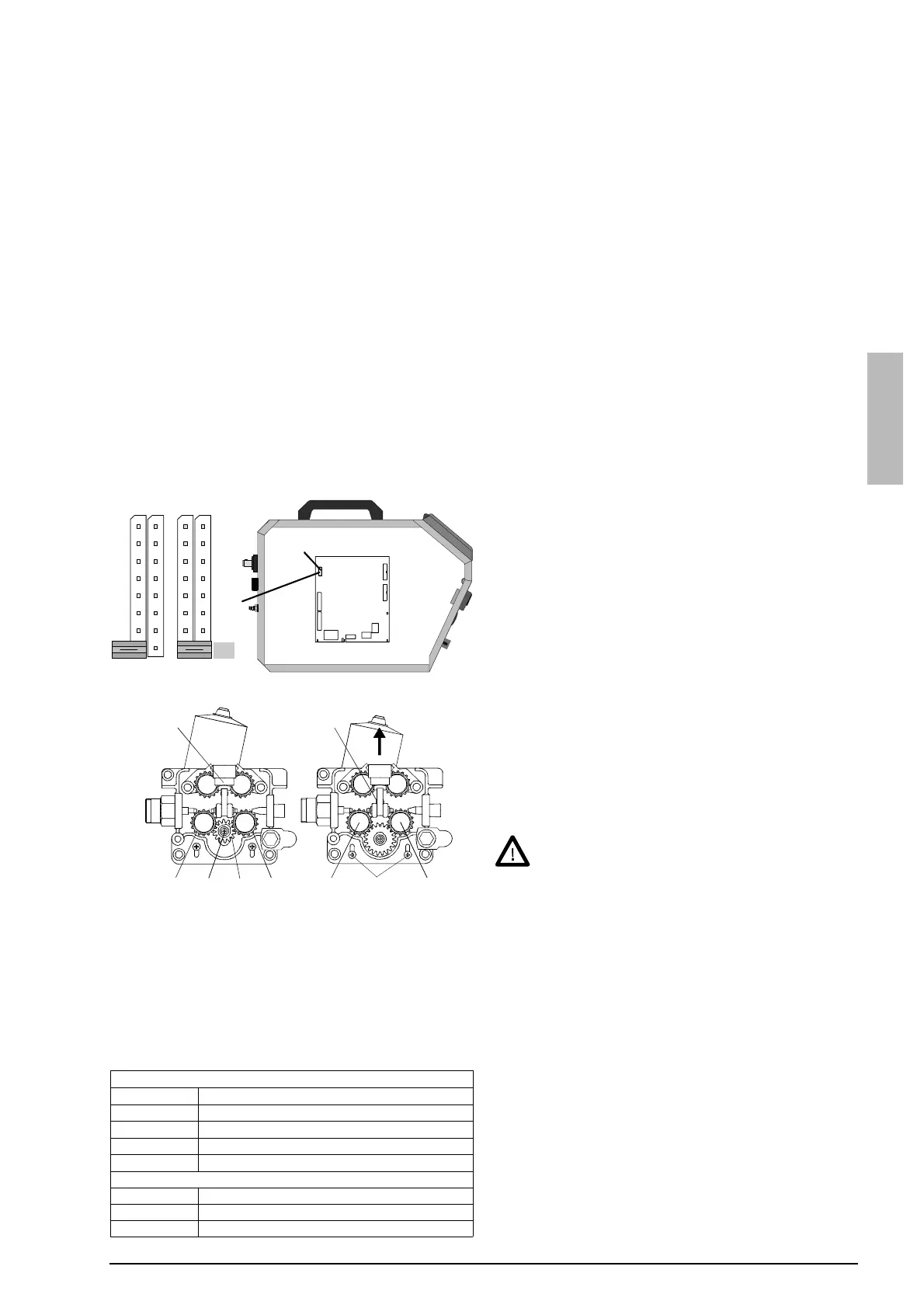

Open tightening lever (20). Remove lower feed rolls

(21). Release screw (23) and its washer. Remove

gear wheel D28 (24) from motor shaft.

Loosen screws (25) (3 pc) 1 twist. Mount the D40

gear wheel onto motor shaft. Screw the screw (23)

with its washer back.

Put feed rolls (21) back to their axles, however don´t

fasten yet fastening screws of the feed rolls (22).

Lift the motor so that the tooth gap between gear

wheel and both lower feed rolls is approx. 0,2 mm.

Tighten screws (25). Check gear teeth gaps, when

necessary put the motor into a better position.

Screw on the mounting screws of feed rolls (22).

Too small gap between gear wheel and feed rolls

will overload motor.

Too big gap for its part might cause too rapid

wearing for teeth of feed rolls and gear wheel.

7. Mounting of push-pull gun´s synchronizing unit SYNC 400 and gas guard GG is described in the operation

instructions, which are delivered with the units.

INSTALLATION

Wire feed mechanism (SL400)

Wire feed rolls are available with plain groove, knurled groove and with U groove for different purposes.

Feed rolls with plain groove:

Universal feed roll for welding of all kinds of wires

Feed rolls with knurled groove:

Special feed roll for cored wires and steel wires

Feed rolls with U groove:

Special feed roll for aluminium wires

Wire feed rolls have two grooves for different filler wire

diameters. Correct wire groove is selected by moving

selecting washer (28) from one side to another in feed

roll.

25 m/min 18 m/min

1

2

3

4

5

6

7

8

A001

JUMPER BLOCK

Loading...

Loading...