EN

5. MAINTENANCE

5.1 Regular maintenance

Check regularly the electrical connections of the machine. Clean any oxidised connections,

and tighten the loosened cable connections.

Let authorised Kemppi service workshop make periodic service to your machine. Appropriate

use and regular service guarantee trouble-free use of the machine. This allows you to avoid

interruptions and increase the productivity of the machine.

NOTE! Remember that the machine may be repaired only by an electrical contractor or installer

authorised to perform such operations.

5.2 Disposal of the machine

Do not dispose of electrical equipment with normal waste!

Electrical equipment that has reached the end of its life must be collected separately and

taken to an appropriate environmentally responsible recycling facility.

The owner of the equipment is obliged to deliver a decommissioned unit to a regional

collection centre, per the instructions of local authorities or a Kemppi representative. By

applying this you will improve the environment and human health.

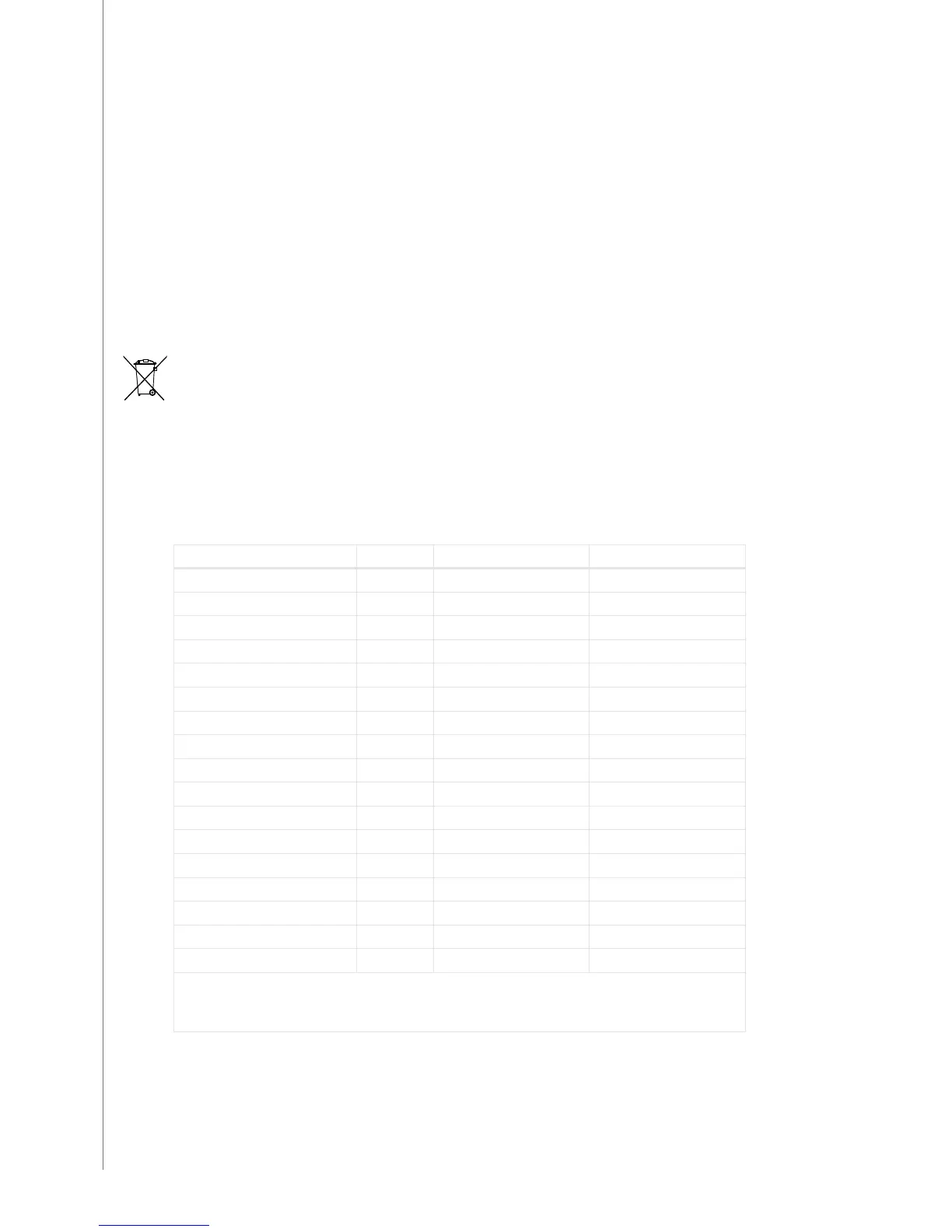

6. TECHNICAL DATA

HiArc M 400R M 500R

Connection voltage

3~, 50/60 Hz 380 – 440 V (-10 %…+10 %) 380 – 440 V (–10 %…+10 %)

Rated power at max. current

60 % ED 17.6 kVA 24.5 kVA

100 % ED 12.5 kVA 17 kVA

Supply current

I

1max

27 A 37 A

I

1e

19 A 29 A

Output at 40 °C

60 % ED 400 A / 34 V 500 A / 39.0 V

100 % ED 310 A / 29 V 390 A / 33.5 V

Fuse (delayed)

25 A 35 A

Open circuit voltage

60 – 70 V 60 – 70 V

Power factor at 60 %

0.90 0.92

Efficiency at 100 %

87 % 87 %

Welding range

13 – 39 V 13 – 50 V

External dimensions

L x W x H 647 x 385 x 485 mm 716 x 385 x 485 mm

Weight

36 kg 41 kg

EMC class

A A

Degree of protection

IP23S IP23S

Gas heater connection

110 V/150 W 110 V/150 W

Standards

IEC 60974-1

IEC 60974-10

HiArc M 400R, M 500R

16

Loading...

Loading...