13

MasterTig ACDC 3500W© Kemppi Oy 2021 R01

OPERATING MANUAL

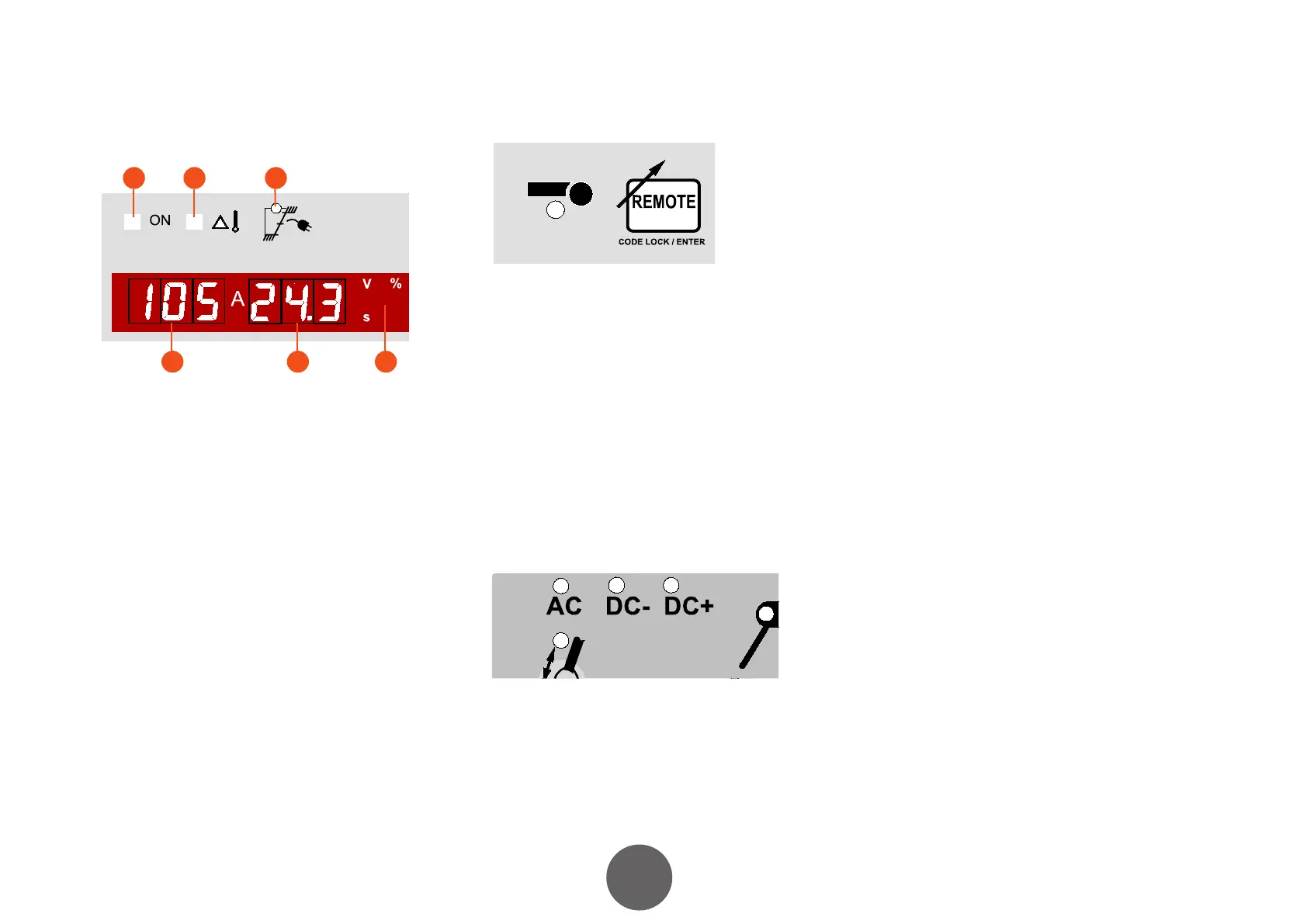

3.1 Numerical displays and signal lights of the

panel

1 2 3

4 5 6

1. Machine on

2. Heat protection

3. Wrong mains voltage, over or under-voltage

4. Display of welding current or set value current

5. Display of welding voltage or parameters

6. Units of the display

The signal light of thermal protection is on when the

machine has over-heated. Let the machine on so that the

fan will cool the machine. Wait until the light goes o, and

you can continue welding.

The light for the wrong voltage turns on if the mains

voltage is too high or too low. Check the voltage setting

of the machine and/or the mains voltage. The wrong

voltage light will also turn on if there is a momentaneous

over-voltage in the mains supply.

The current is displayed with a tolerance of 3 % ± 2 A; the

voltage with a tolerance of 3 % ± 0.2 V.

3.2 Use of the remote control

The remote control is selected from the key REMOTE. With

the remote control you can adjust the welding current

of MMA and TIG welding. The values of the parameters

(up-slope and down-slope times, gas ow times etc.) are

adjusted from the current knob.

With remote control unit C 100AC you can also change

the welding method (MMA / TIG). The machine selects the

polarity (type of current) in accordance with an advance

selection on the panel.

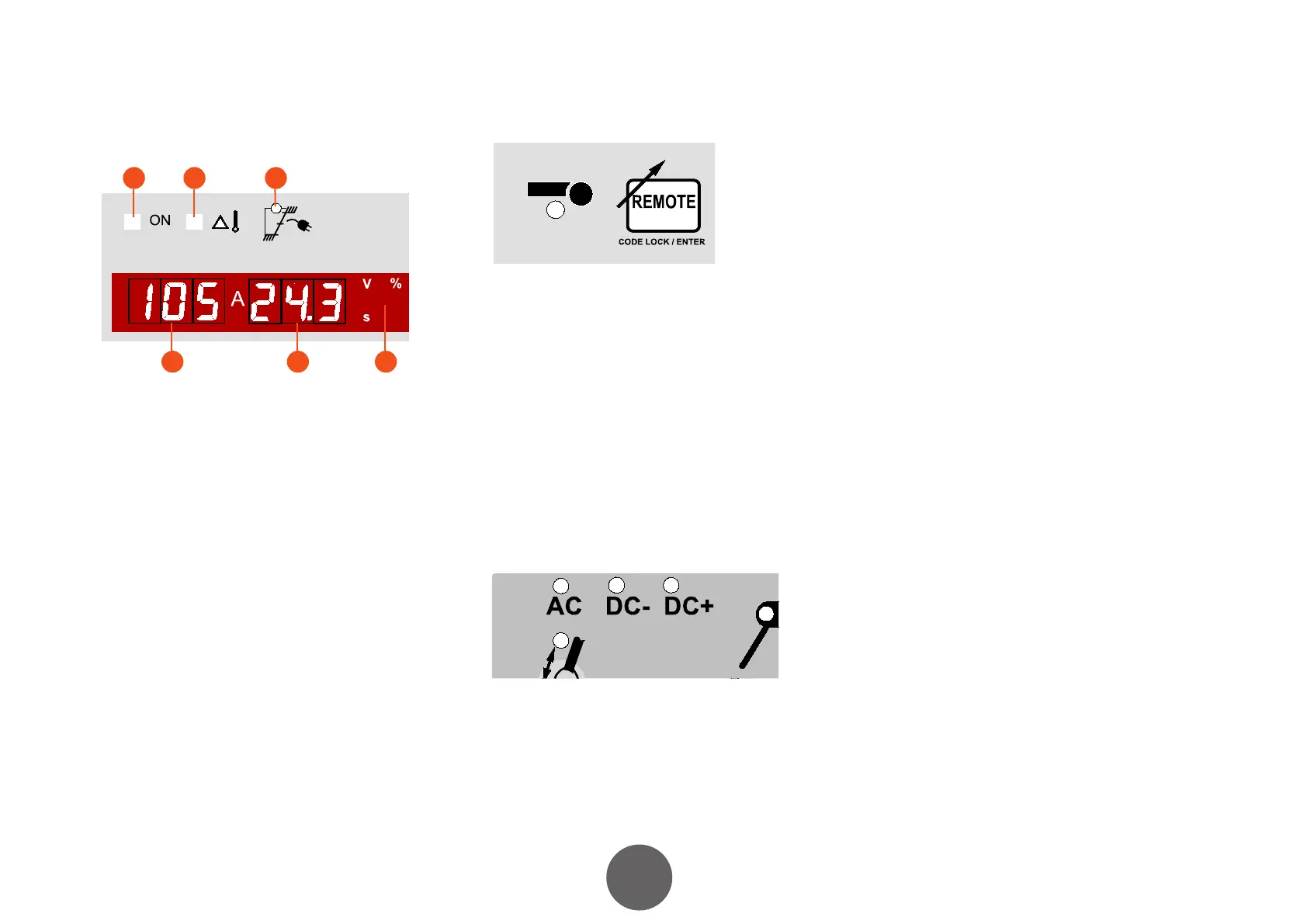

3.3 MMA welding

3.3.1 Selection of type of current

Select MMA welding by pressing the selection key of

MMA welding. The signal light of the type of current

indicates the current type selected: AC, DC-, DC+.

Change the current type by pressing the MMA selection

key again and the current type will change and the signal

light will show the current type selected.

3.3.2 Broken arc method

Press the BROKEN ARC key and the signal light for broken

arc method turns on.

A broken arc method has to be used if the seam to be

welded cannot tolerate the heat of a continuous arc. The

heat of the welding is controlled by breaking the arc.

Usually the reason is thin material or various ttings. In

the broken arc method position, the arc breaks faster

and the ignition pulse is smaller then in ordinary MMA

welding.

3.3.3 Control of MMA welding dynamics (only with

minilog and pulse panels)

Press the DYNAMICS key and you will see the numerical

value corresponding to the dynamics in the display.

You can change the value by turning the current knob.

Numerical value zero is the normal setting for all MMA

electrodes. When the value is adjusted negative (-1...

9), the arc is softened. The amount of spatter decreases

when welding at the upper end of the recommended

current range of the electrode. On the positive side (1...9)

the arc is rough.

It is suitable e.g. for thin stainless steel rods when welding

near the lower end of the recommended current range.

Loading...

Loading...