7

MasterTig ACDC 3500W© Kemppi Oy 2021 R01

OPERATING MANUAL

2.6 Electrodes to be welded

With the Mastertig AC/DC power source you can use all

electrodes designed for DC or AC welding within the

current limits of the machine in question.

Mastertig AC/DC 3500W power source is suitable

for carbon arc gouging and cutting according to its

maximum power.

Reference max electrode diameters and yield

electrode type yield 3500W

Fe-rutile 95 % ø 6

Fe-base 100 % ø 6

Fe-high-yield 180 %

250-270 %

ø 5

ø 5

Ss-rutile - - - ø 6

Ss-base - - - ø 6

Ss-high-yield 150 % ø 6

Hard facing by

welding

100 % ø 6

2.7 TIG DC welding

DC– current is used typically when welding dierent kind of steel. We rekommend for DC– welding

a WC20 (grey) elctrode.

2.7.1 Sharpening of the electrode

The tip of the electrode is sharpened into a cone, so that the arc becomes steady and the thermal

energy is concentrated on the spot being welded. The length of the sharpening to the diameter of

the electrode:

with small current sharp l = 3 x d

with large current blunt l = 1 x d

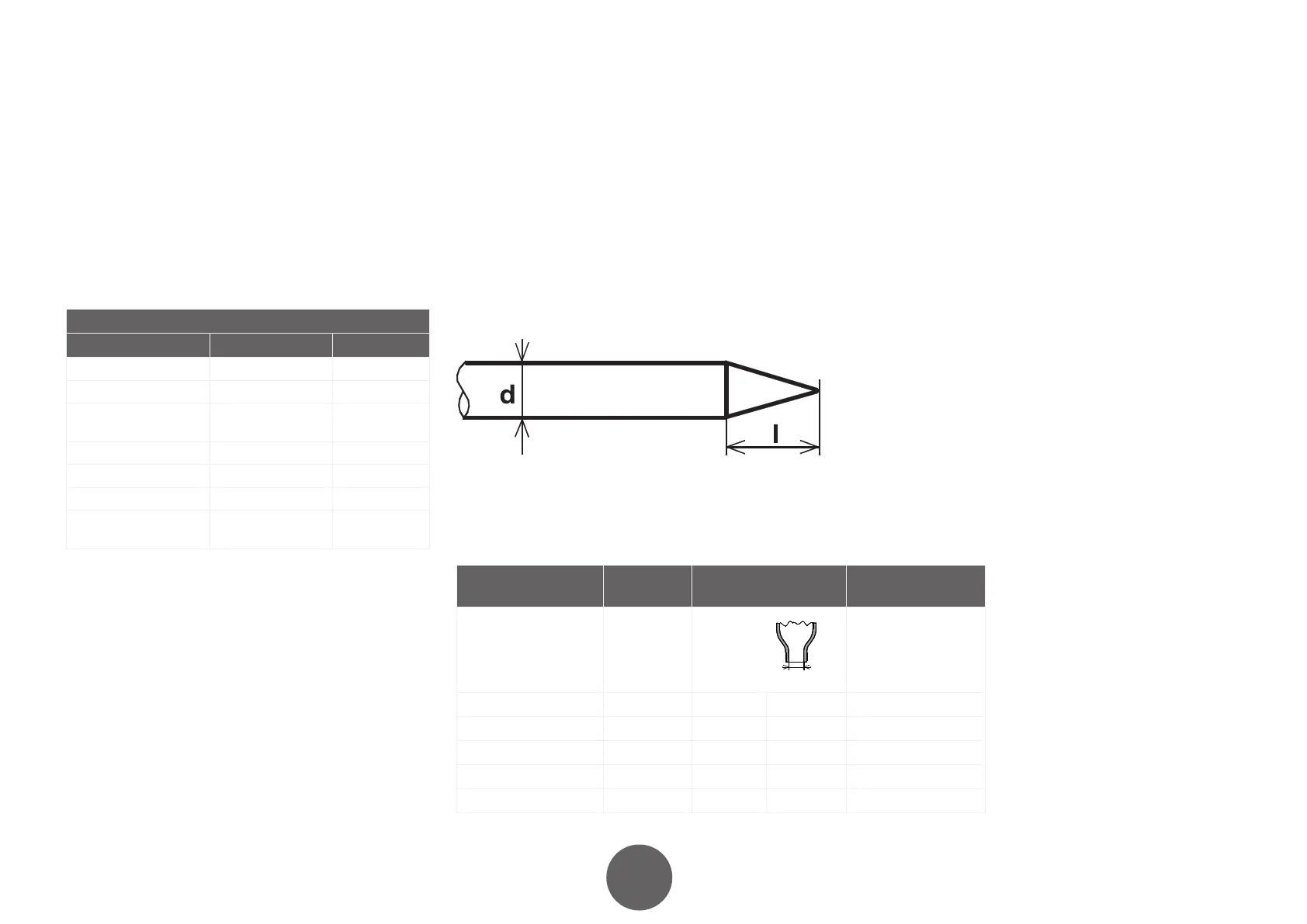

Choice of the electrode for DC welding. The table is only given as a guide.

Welding current

range

Electrode Gas nozzle Gas ow rate

DC-

A

WC20

ø mm

number ø mm

Argon

l / min

5...80 1.0 4/5 6.5/8.0 5...6

70...140 1.6 4/5/6 6.5/8.0/9.5 6...7

140...230 2.4 6/7 9.5/11.0 7...8

225...350 3.2 7/8 11.0/12.5 8...10

330...350 4 10 16 10...12

Loading...

Loading...