EN

2.10 SHIELD GAS

NOTE! Handle gas bottle with care. There is a risk for injury if gas bottle or bottle valve is damaged!

Use inert gases such as argon, helium or argon-helium mixture as shield gas for TIG welding.

Make sure that the gas ow regulator is suitable for the gas type used. The ow rate is set

according to the welding current, joint form and the size of the electrode. A suitable ow rate

is normally 8 – 10 l/min. If the gas ow is not suitable the welded joint will be porous. Spark

ignition becomes more dicult if the gas ow is too high. Contact your local Kemppi dealer

for choosing gas and equipment.

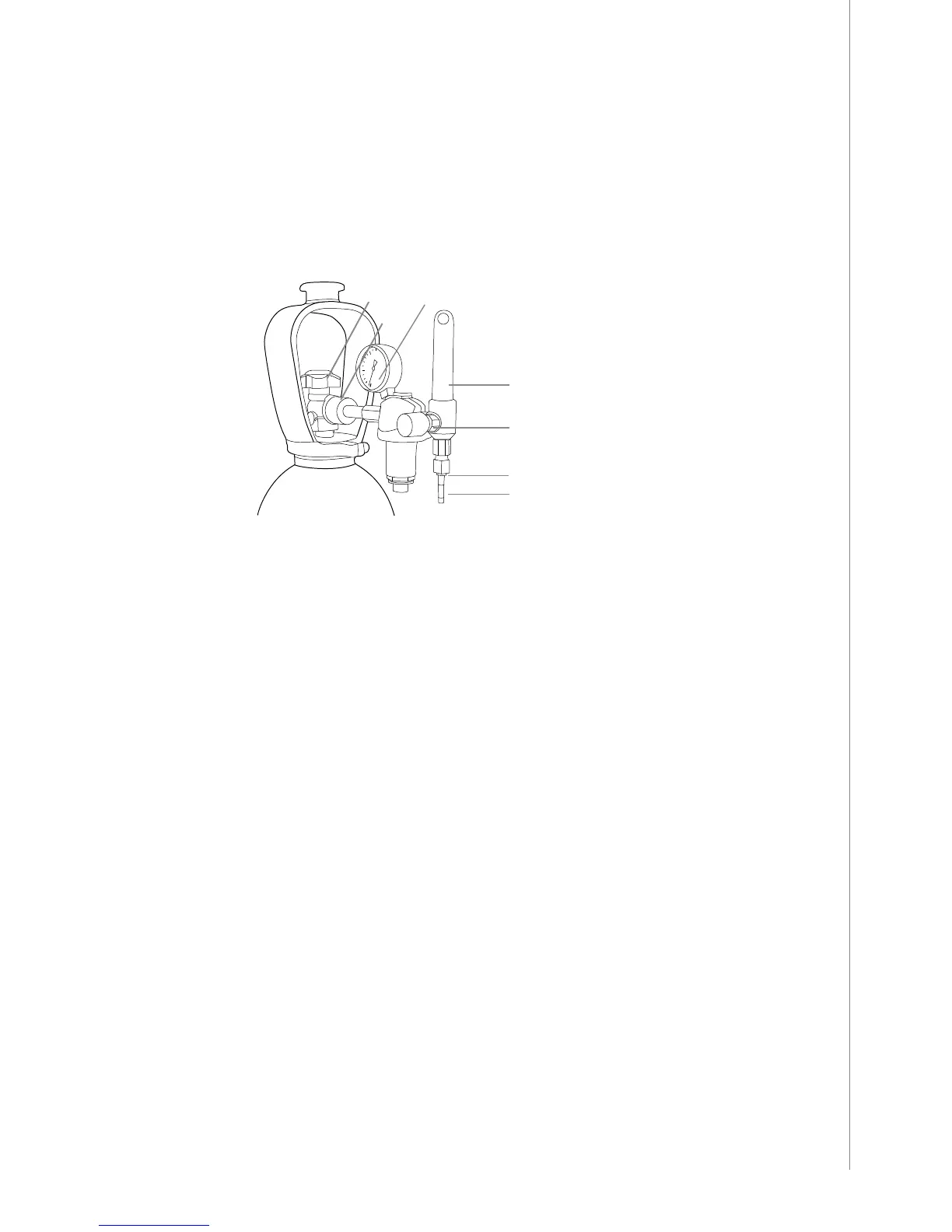

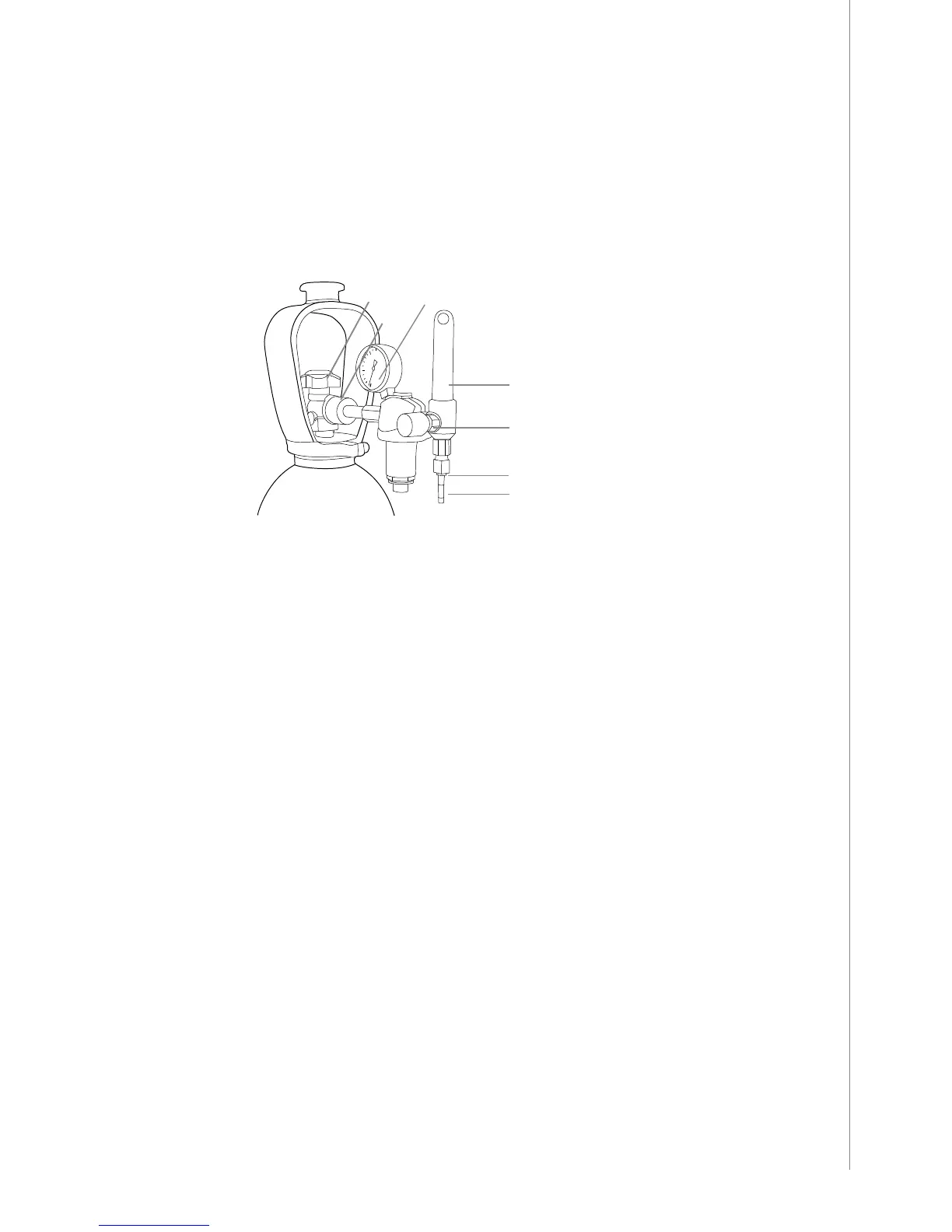

E

B

D

G

A

F

C

Parts of gas ow regulator

A. Gas bottle valve

B. Pressure regulation screw

C. Connecting nut

D. Hose spindle

E. Jacket nut

F. Gas bottle pressure meter

G. Gas hose pressure meter

2.10.1 Installation of gas bottle

NOTE! Always fasten gas bottle properly in vertical position in a special holder on the wall or on a

carriage. Remember to close gas bottle valve after having nished welding.

The following installation instructions are valid for most gas ow regulator types:

1. Step aside and open the bottle valve (A) for a while to blow out possible impurities from the

bottle valve. Note! Watch out for the gas ow.

2. Turn the press regulation screw (B) of the regulator until no spring pressure can be felt.

3. Close needle valve if there is one in the regulator.

4. Install the regulator on bottle valve and tighten connecting nut (C) with a wrench.

5. Install hose spindle (D) and jacket nut (E) into gas hose and tighten with hose clamp.

6. Connect one end of the hose with the regulator and the other end with the power source.

Tighten the jacket nut.

7. Open bottle valve slowly. Gas bottle pressure meter (F) shows the bottle pressure.

NOTE! Do not use the whole contents of the bottle. The bottle should be lled when the bottle

pressure is 2 bar.

8. Open needle valve if there is one in the regulator.

9. Turn regulation screw (B) until hose pressure meter (G) shows the required ow (or pressure).

When regulating ow amount, the power source should be switched on and the gun

switch pressed simultaneously.

Close bottle valve after having nished welding. If the machine will be out of use for a long

time, unscrew the pressure regulation screw.

9

MasterTig MLS 3000, 3003 ACDC / © Kemppi Oy / 1112

Loading...

Loading...