EN

3. OPERATION

NOTE! Welding in places presenting an immediate re or explosion hazard is forbidden!

NOTE! Welding fumes may cause injury, take care of sucient ventilation during welding!

3.1 WELDING PROCESSES

3.1.1 MMA welding

With Mastertig MLS™ ACDC power sources you can use almost all electrodes suitable for direct

and alternating current welding between current limits of the power source. Both function

panels (ACS, ACX) can be used for electrode welding when MMA welding is selected.

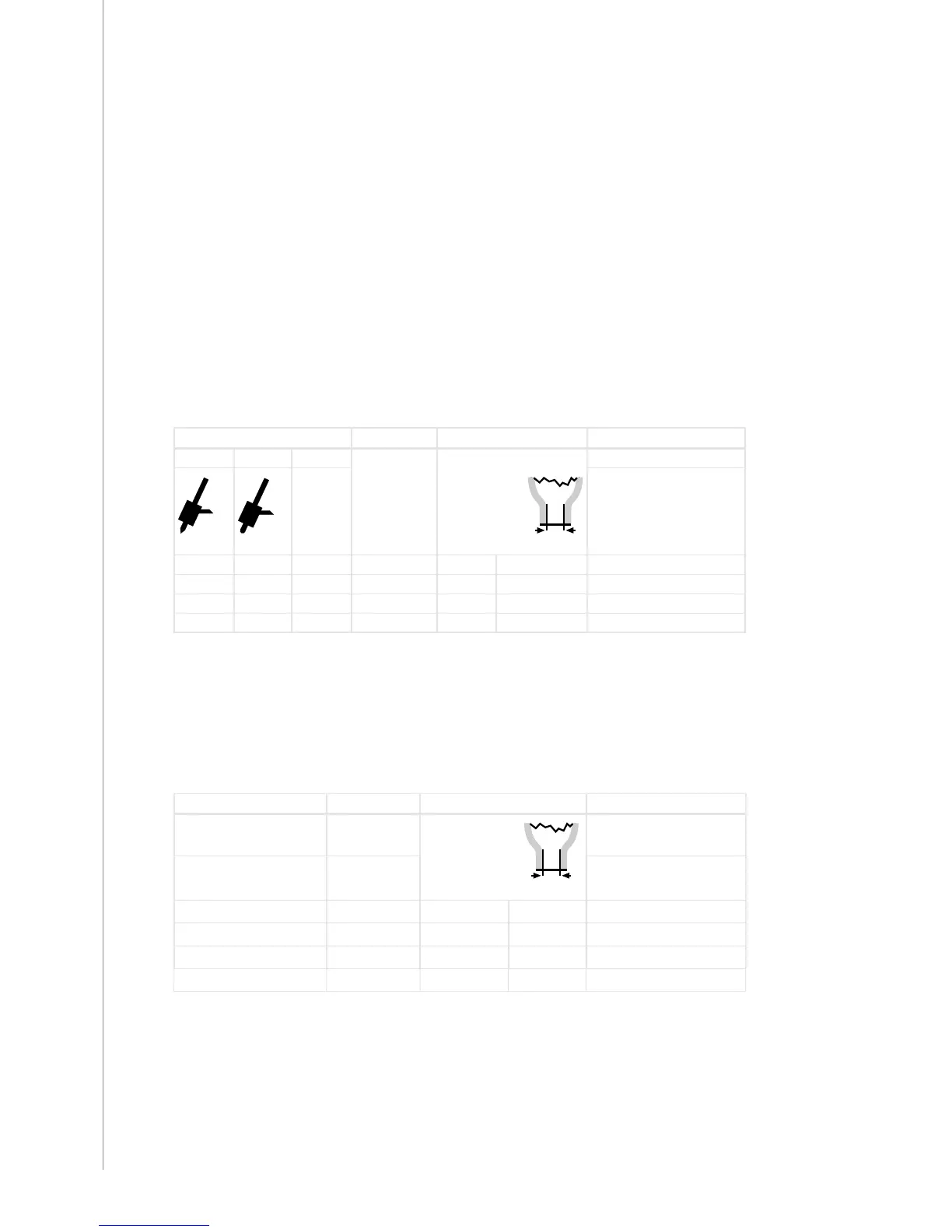

3.1.2 TIG welding Alternating Current

The Mastertig ACDC MLS™ power sources are specially designed for TIG welding aluminium

with alternating current (AC). We recommend using WC20 electrodes (grey) for AC welding.

The table is only given as a guide.

Welding current range AC Electrode Gas nozzle Gas flow rate

min. min. maks. WC20

ø mm number ø mm

Argon

A A A l/min

15 25 90 1.6 4 / 5 / 6 6.5 / 8.0 / 9.5 6...7

20 30 150 2.4 6 / 7 9.5 / 11.0 7...8

30 45 200 3.2 7 / 8 / 10 11.0 / 12.5 / 16 8...10

40 60 350 4.0 10 / 11 16 / 17.5 10...12

The table and the panel scale are based on the use of WC20 (grey).

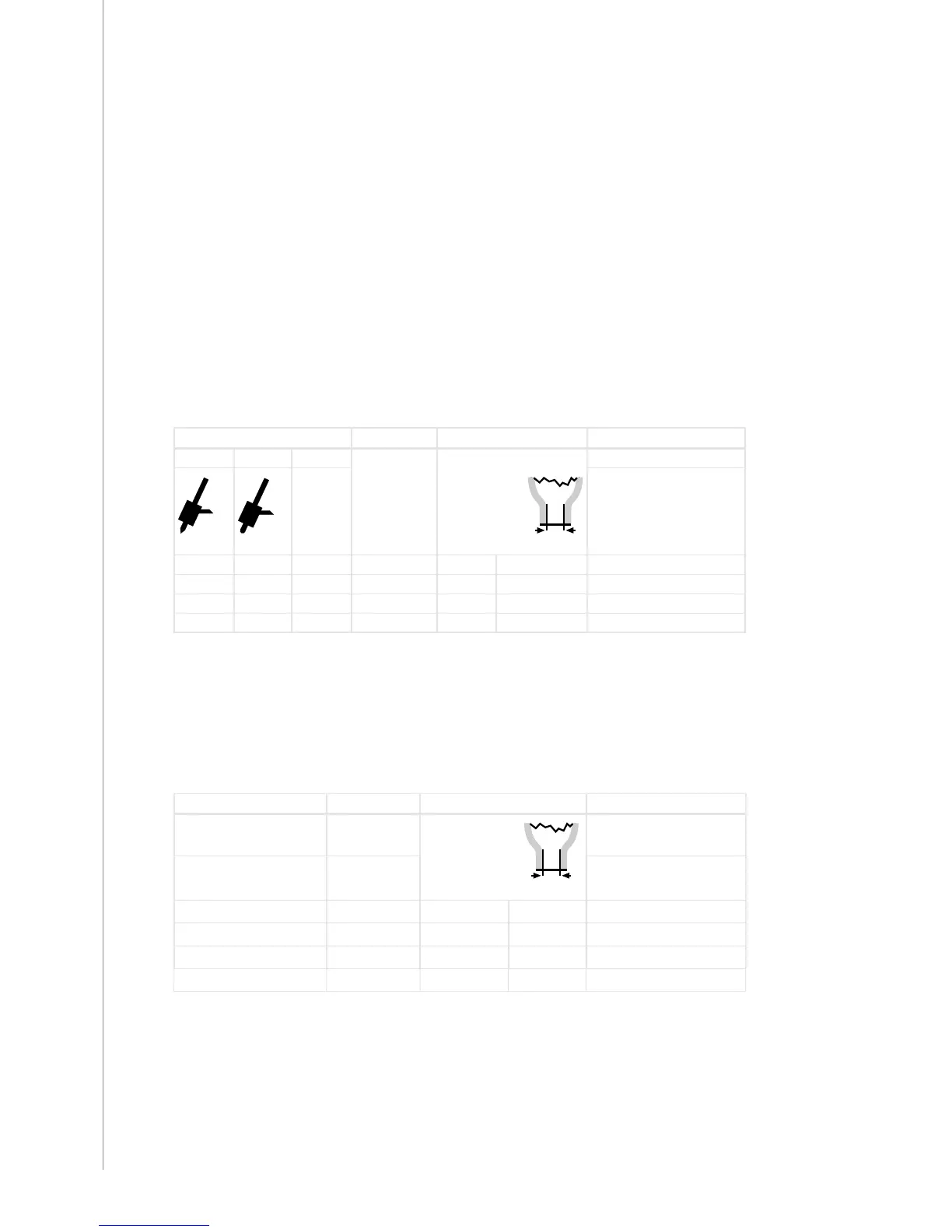

3.1.3 TIG Welding with Direct Current

DC welding is typically used when welding dierent grades of steel. We recommend using

WC20 electrodes (grey) for DC welding.

A directive electrode selection table for DC welding.

Welding current range DC Electrode Gas nozzle Gas flow rate

WC20

number ø mm

Argon

A ø mm l/min

5...80 1.0 4/5 6.5 / 8.0 5...6

70...140 1.6 4 / 5 / 6 6.5 / 8.0 / 9.5 6...7

140...230 2.4 6 / 7 9.5 / 11.0 7...8

225...330 3.2 7 / 8 / 10

11.0 / 12.5 / 16 8...10

10

MasterTig MLS 3000, 3003 ACDC / © Kemppi Oy / 1112

Loading...

Loading...