EN

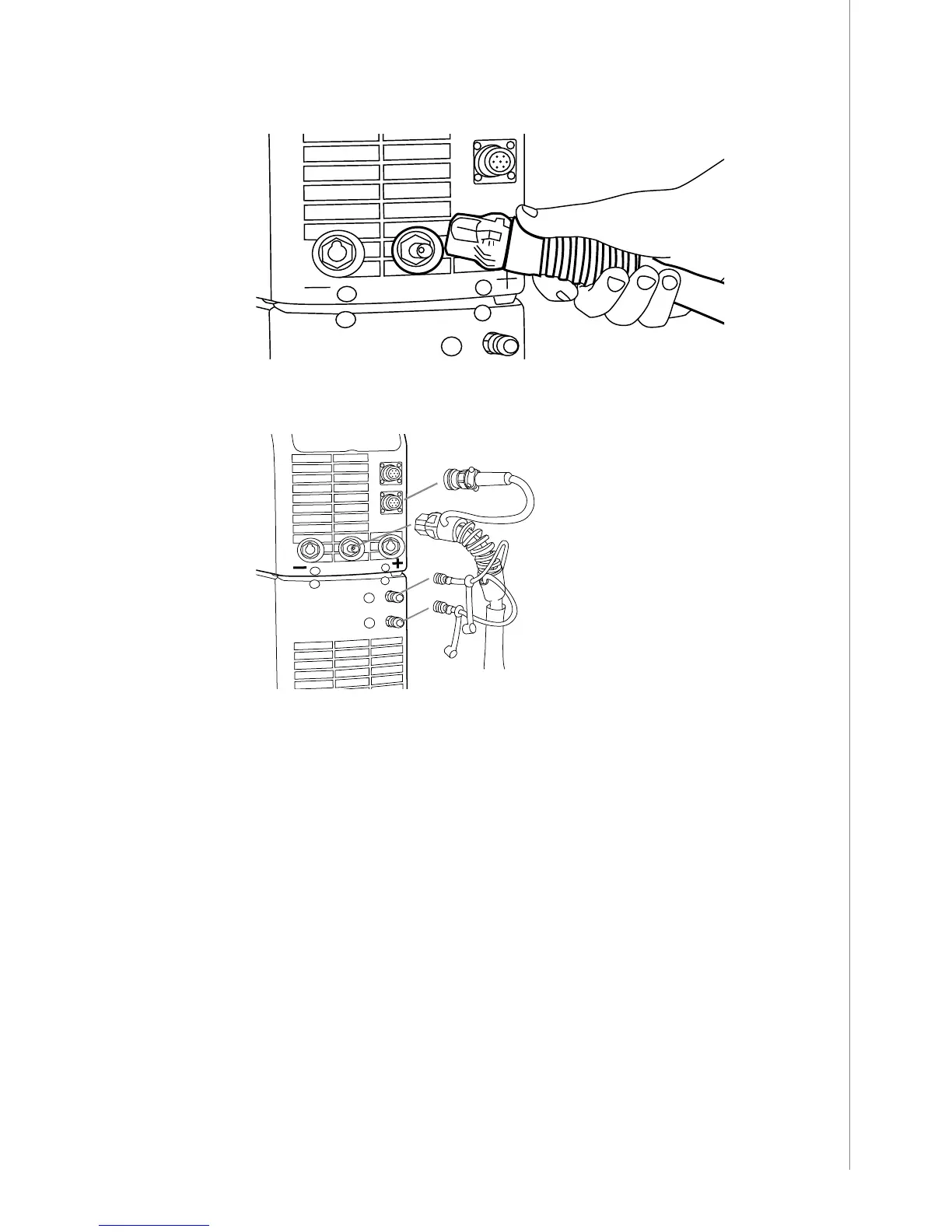

Installing gas-cooled torch

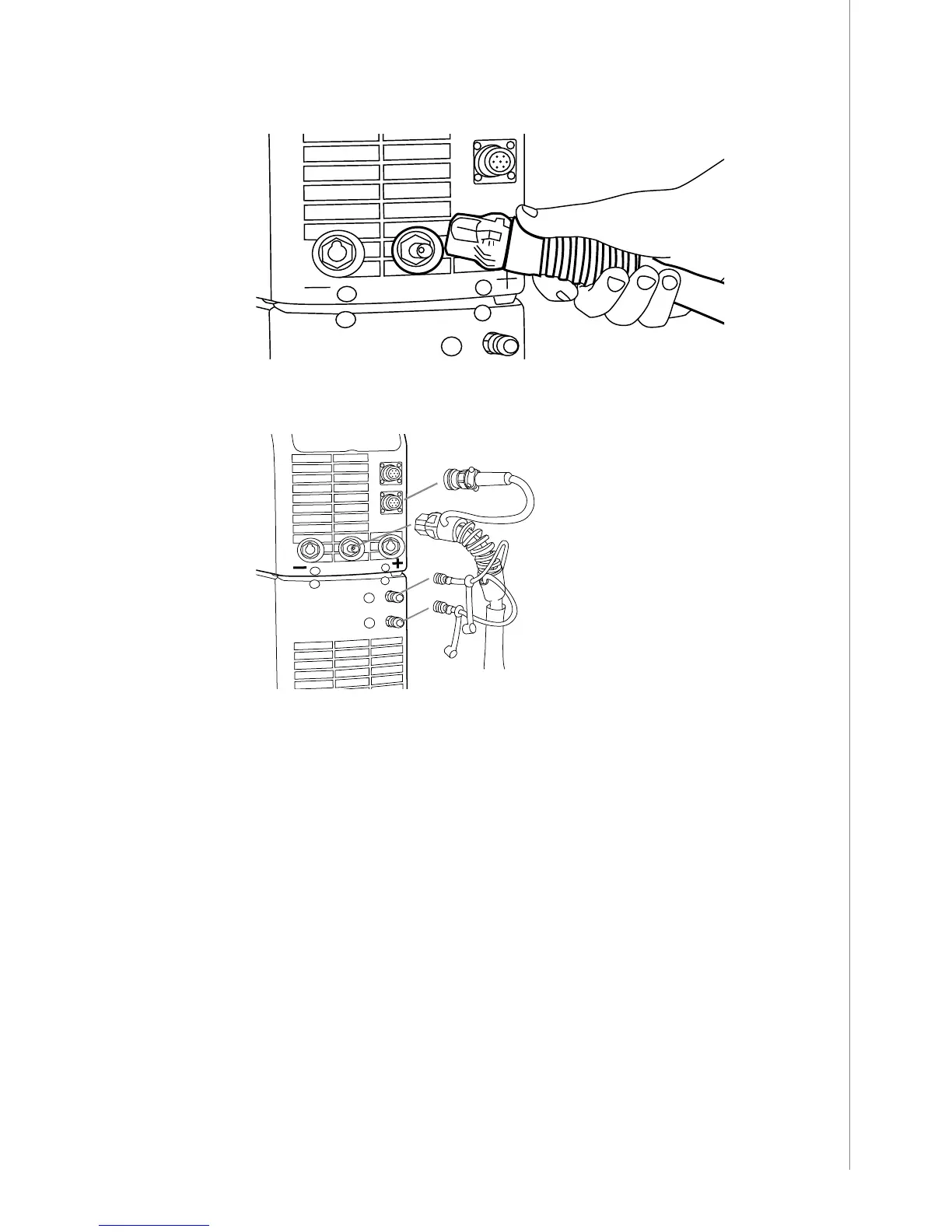

Installing water-cooled torch

Connect the red water hose to the upper connector and blue one to the lower connector..

2.10 SHIELD GAS

NOTE! Handle gas bottle with care. There is a risk for injury if gas bottle or bottle valve is damaged!

Use inert gases such as argon, helium or argon-helium mixture as shield gas for TIG welding.

Make sure that the gas ow regulator is suitable for the gas type used. The ow rate is set

according to the welding current, joint form and the size of the electrode. A suitable ow rate

is normally 8 – 10 l/min. If the gas ow is not suitable the welded joint will be porous. Spark

ignition becomes more dicult if the gas ow is too high. Contact your local Kemppi dealer

for choosing gas and equipment.

7

Master, MasterTig, MasterCool 10 / © Kemppi Oy / 1112

Loading...

Loading...