EN

earthing cable to the negative connector.

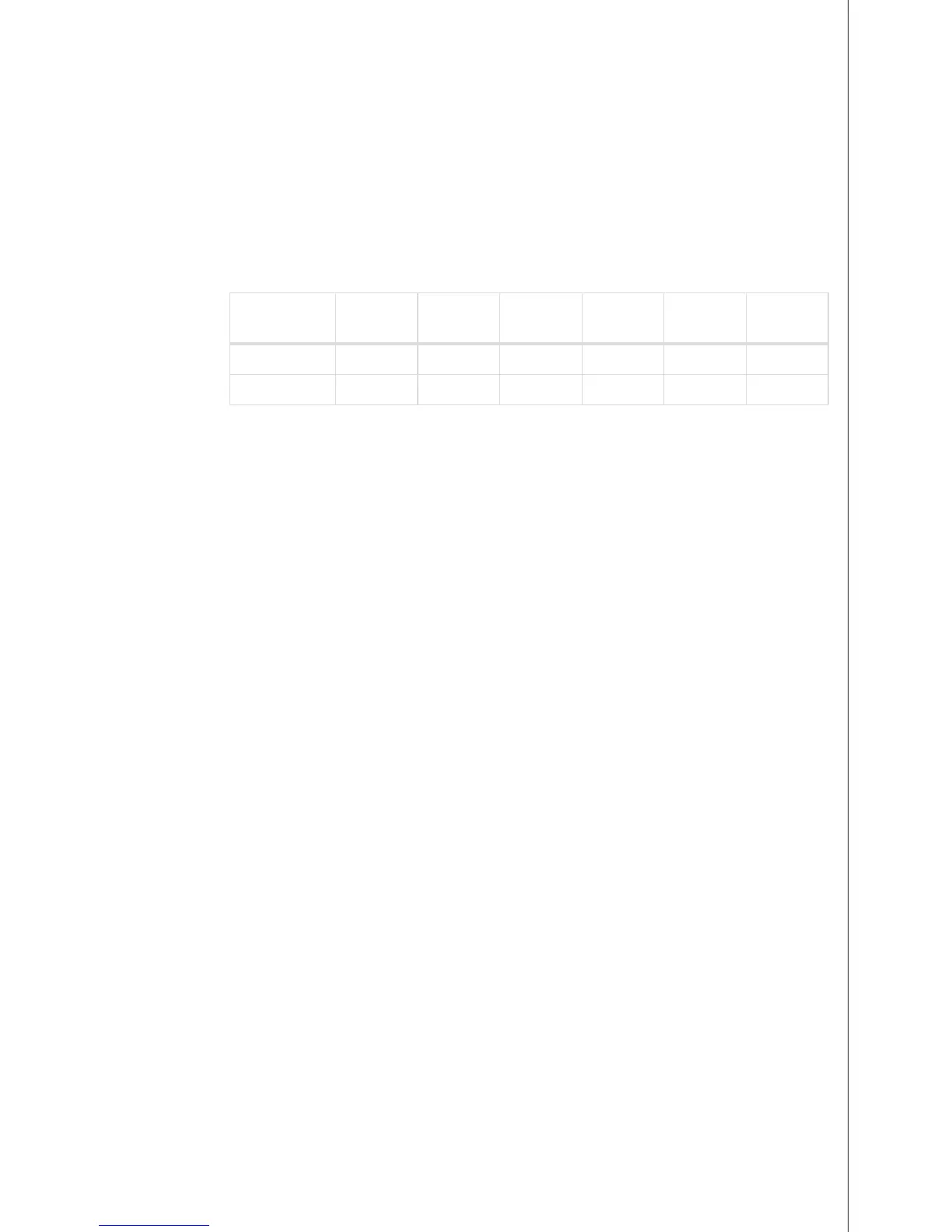

It is also important to properly adjust the welding current so that the ller

material and coating will melt properly and the welding is ecient. The table

below presents the electrode sizes available with the Minarc 220 welding

machine and the corresponding welding current values.

MMA Electrodes and corresponding current settings range

Electrode

diameter

1.6 mm 2.0 mm 2.5 mm 3.25 mm 4.0 mm 5.0 mm

Fe-Rutile

30-60 A 40-80 A 50-110 A 80-150 A 120-210 A 170-220 A

Fe-Basic

30-55 A 50-80 A 80-110 A 110-150 A 140-200 A 200-220 A

TIG welding electrodes and gas nozzles

In DC TIG welding we recommend the use of the WC20 (grey) type electrode,

however other types are available.

The welding electrode size (diameter) is selected depending on the welding

current/power to be used. An electrode with an insucient diameter

compared to the welding current will melt, while excessive electrode size will

make it more dicult to ignite the arc.

Generally speaking, a 1.6 mm tungsten electrode will cover currents up to

150 A, and 2.4 mm tungsten electrode up to 250 A DC current.

Before use, grind the tungsten electrode to a sharp point at approximately

1.5 times the diameter of the electrode.

7

Minarc 220 / © Kemppi Oy / 1117

Loading...

Loading...