Hot Water Cleaner Batch 1015-1030

Kent high pressure\Hot Water 1015-1030\Brugs-Hedvand-EN-e.237.doc

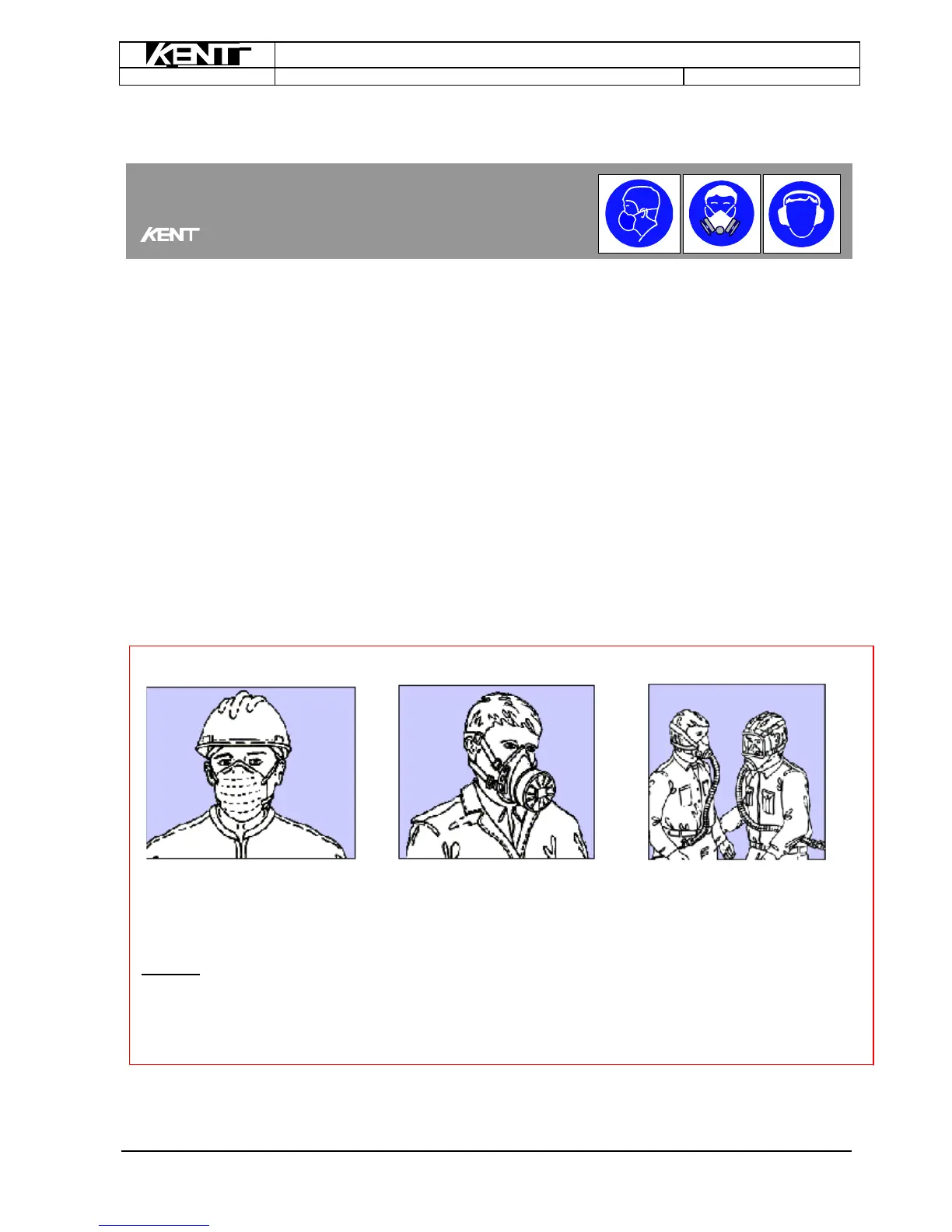

Respiratory Equipment/Ear Defenders (Danish At Guidelines D. 2.20 November 2006):

When working under 2.5 MPa (25 bar) and if there are aggravating factors such as chemicals that are harmful to

health when inhaled, micro-organisms or residues of organic origin present, the employee shall wear appropriate

respiratory equipment.

Appropriate respiratory equipment shall always be used when working over 2.5 MPa (25 bar).

Respiratory equipment must feature a filter of at least class P2, which provides protection against solid particles

and liquid aerosols. The safest thing to do is to use respiratory equipment with an on-board air supply. There can

often be doubt as to the nature and concentration of air pollution, because it can be difficult to determine what

materials are removed from surfaces that have been pressure-washed. If the employee is to spend more than

three hours a day working with a pressure washer, the respiratory equipment used must have an on-board air

supply or feature filtration supplemented by a turbo unit (fan).

Inhalation of aerosols containing surfactants (e.g. soap) and grease and protein residues heightens the risk of the

development of respiratory ailments and is also a mucosal irritant (3).

The employer shall ensure that employees use ear defenders as soon as work that is deemed to be damaging to

hearing begins. In other words, even at noise levels below 85 dB(A), ear defenders must be worn (4).

Respiratory equipment and ear defenders must fit together, and should preferably be tested together.

Class P2

filters have better filtration characteristics and therefore provide more extensive protection. They protect against

harmful and toxic dust, but not against radioactive dust, bacteria and viruses. These filters can protect only

against solid particles or against both solid particles and liquid aerosols. If the filter has been certified in accor-

dance with EN149:2001, it affords protection against both solid particles and liquid aerosols. For more information,

see At Guidelines D.5.4 January 2008.

Filtering respiratory mask.

Particle filters are divided into three

classes: P1 low effect filter

P2 medium effect filter

P3 high effect filter

Respiratory equipment with on-

board air supply

At Guidelines D.5.4 January 2008:

When planning work, it must be remembered that aerosols, especially small particulate, remain in the

air for a long time, even after pressure work has stopped. Therefore, it will often be necessary to use

personal protective equipment, even after pressure work has stopped. The smallest aerosol particu-

lates can remain in the air for up to 1.5 hours.

Loading...

Loading...