5.

TROUBLESHOOTING

TROUBLE

POSIBLE

CAUSE

SOLUTION

2.

Zero

production.

• There is no

water supply.

•

There is no power supply.

•

Leaking sensor activated.

•

Wait for the supply to return.

•

Check the electrical supply of the location. If the problem

is not solved, call the technical service.

•

Leaking sensor activated. If the leak is not visible, dry the

bottom of the equipment and the leaking sensor well. If it re-

occurs, call the technical service.

4.

Excessive

production. • Excessive chlorine entry into the membrane.

• Blocked rejection valve, flow rate less than 1

liter per minute.

• Excessively high supply water temperature

>38ºC.

• Replace membrane.

• Change of reject valve.

• The water temperature must be reduced below the limits.

• Check general installation of the enclosure, to eliminate heat

sources.

6.

White

colored

water.

•

Air in the system. Microbubbles of air that

disappear after a few seconds.

•

It is not a problem. The appearance will disappear as the air

inside the equipment is expelled.

8.

The equipment does not

start.

•

There is no water supply.

•

There is no power supply.

•

Leaking sensor activated.

•

Check the general condition and the inlet of the equipment.

•

Check the general power supply. If the problem is not solved,

call the technical service.

•

If the leak is not detected, dry the bottom of the unit toge-

ther with the leaking sensor. If it reoccurs, call the technical

service.

10.

The equipment never stops

expelling water to the drain.

•

Inlet solenoid valve damaged.

•

Deteriorated production check valve.

•

Check and replace.

•

Check and replace.

9. The equipment stops and

starts constantly

•

Several possible causes.

7. Continuous dripping noise

in drain.

•

Several possible causes.

5. Unpleasant

taste and smell.

• Several possible causes.

•

Call

for

service.

•

Inlet tap partially closed.

•

Filters / membrane in poor condition.

•

Open it completely.

•

Call for service.

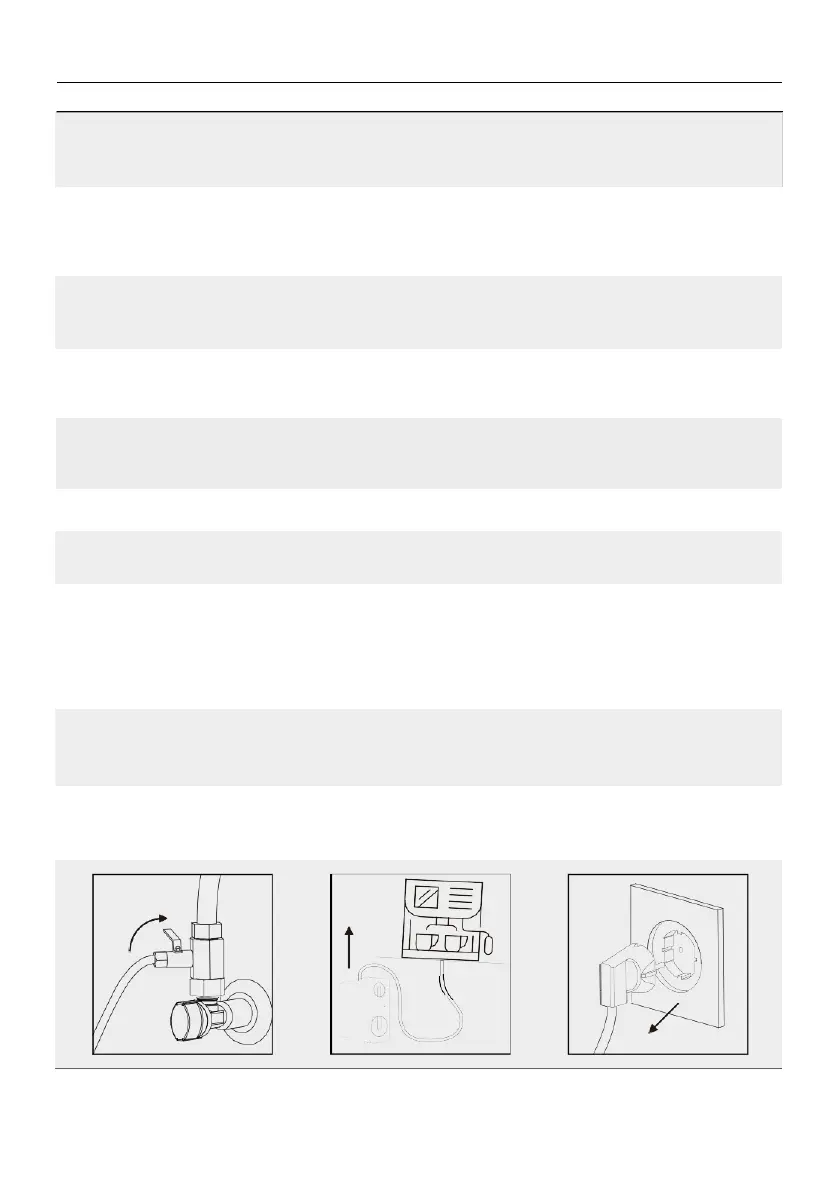

1.

Leak

to

the

outside

the

equipment.

•

Several possible causes.

Loading...

Loading...