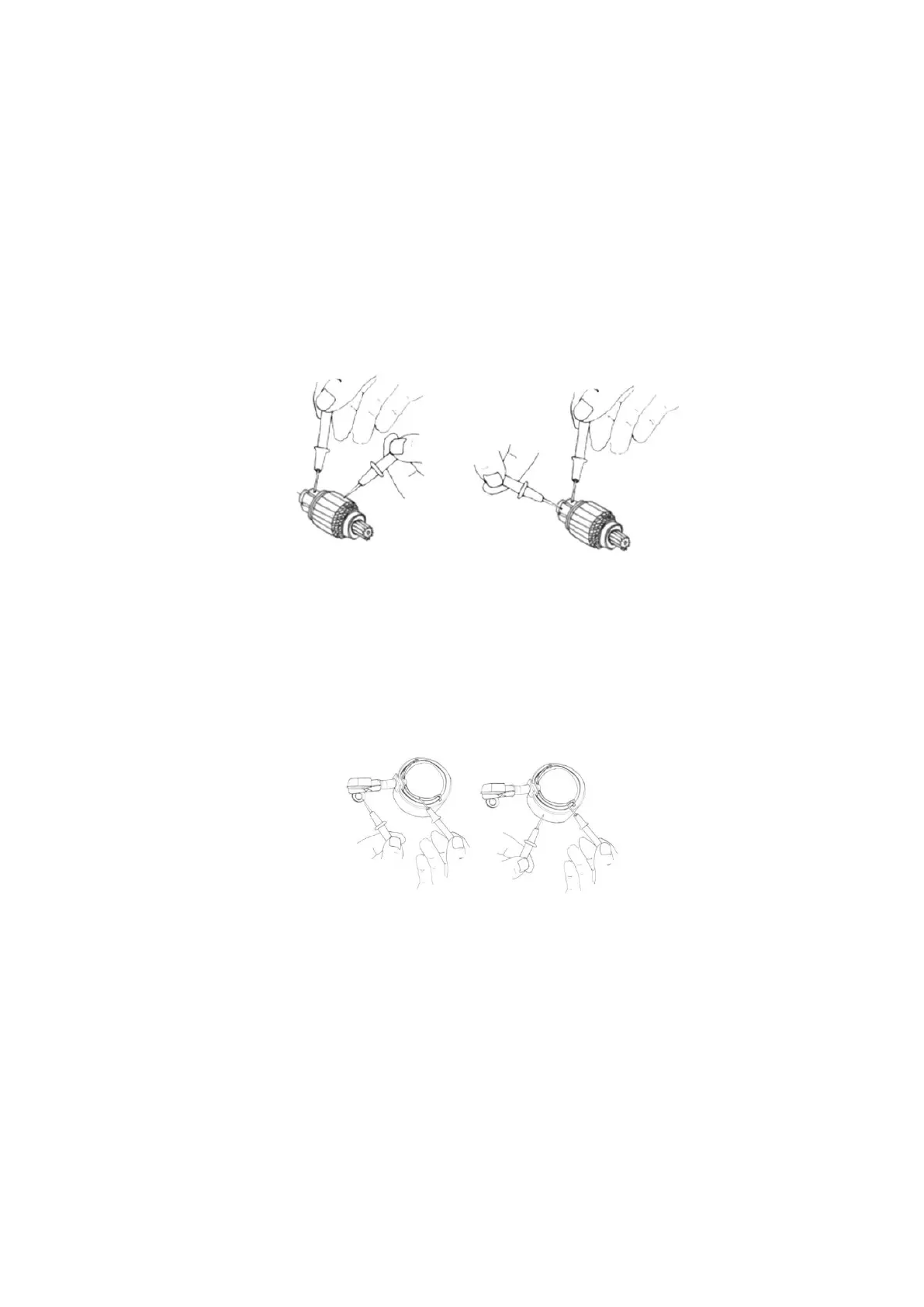

1.6.4 Check armature Refer to Fig 67

Check the electric conductivity with ohmmeter between the commutator copper sheet and the

armature core or armature winding:

(1)If the commutator copper sheet and armature core are current conducting, please replace

armature.

(2)If commutator copper sheet and armature winding are not current conducting, please

replace armature.

(3)If the commutator copper sheet is current conducting each other, please replace armature.

(Refer to Fig 68)

Fig 67 Fig 68

Engine electrical system

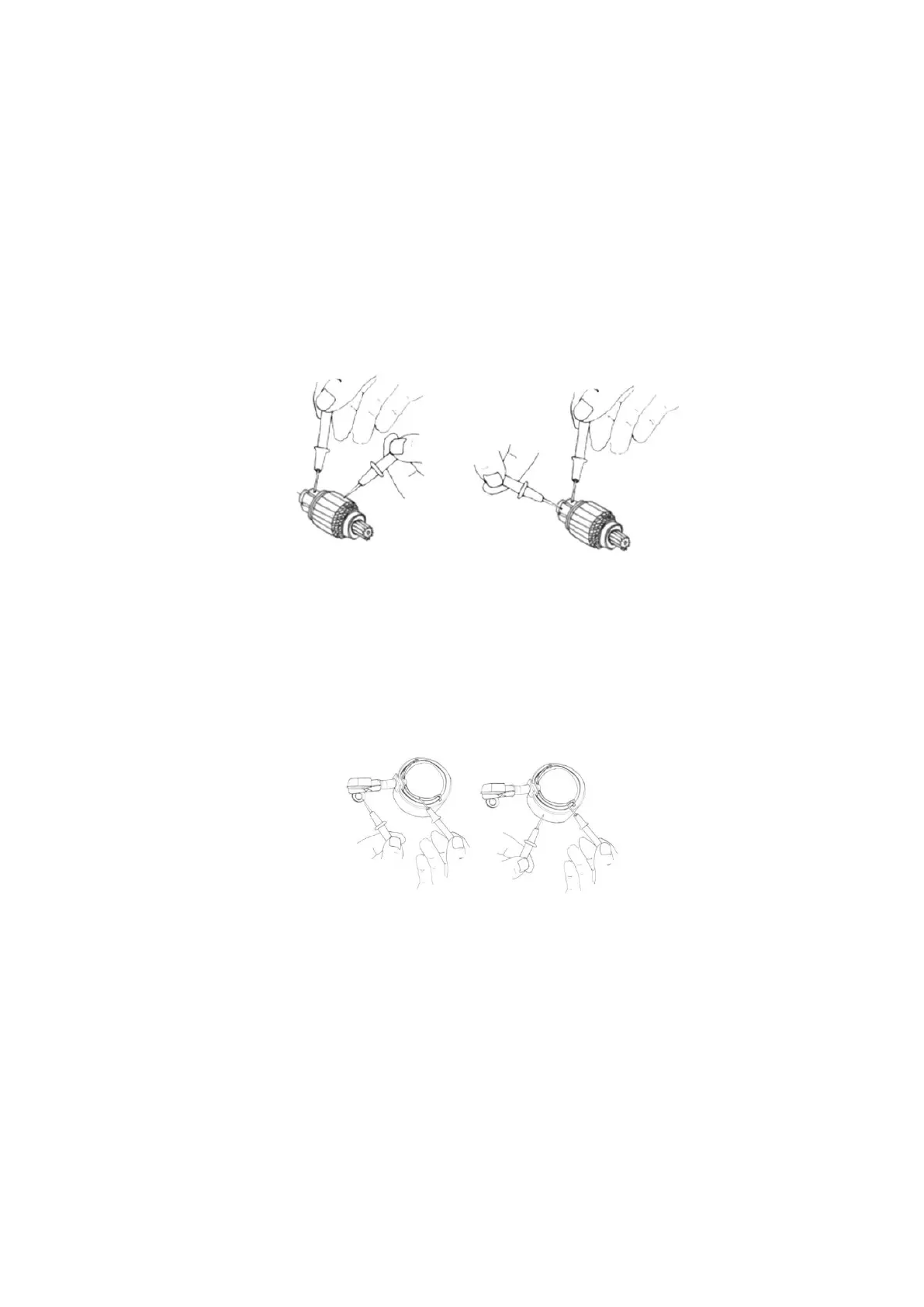

1.6.5 Check stator winding

(1) Test electricity of stator winding outgoing line with an ohmmeter, if no conductivity, please

replace stator. Refer to Fig. 69

(2) Test insulatibity between stator winding and stator shell with an ohmmeter, if it is conductive,

please replace stator. Refer to Fig.70.

Fig. 69 Fig. 70

1.6.6 Check armature roll bearing

Small radial and axial clearance, smooth running of roll bearing. If big vibration, clagging or

damages happen, please replace the roll bearing.

1.6.7 Check retarder clutch. Refer to Fig.71

(1) Check all gears of retarder clutch, if severe aging or damage happens, please replace

retarder clutch or related gear.

(2) Check flexibility of retarder clutch. Smooth radial operation and rotation must be secured.

No skid when given a force, normal performance maintained, otherwise please replace.

Loading...

Loading...