Do you have a question about the KIRLOSKAR 8 UP 200/38 and is the answer not in the manual?

Explains pump nomenclature with model type, size, and diameter examples.

Provides general safety guidance, responsibilities, and pump nameplate importance.

Covers safe practices for transporting, handling, and storing the pump unit.

Safety guidelines for general use, installation, operation, commissioning, maintenance, and servicing phases.

Details visual checks, preparation, and location selection for pump installation.

Requirements for foundation, baseplate setting, and grouting procedures for stability.

Explains how to align pump and driver shafts accurately and factors affecting alignment.

Guidelines for installing suction and discharge piping correctly, including pipe sizing and layout.

Inspection checklist and procedures before the initial start-up of the pump.

Procedures for starting, running checks, monitoring, and safely stopping the pump.

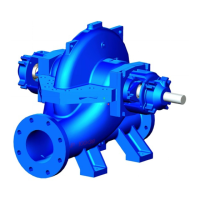

Details pump types, rotation, bearing models, and lubrication requirements.

Details impeller types, wear ring clearances, stuffing box packing, and mechanical seal information.

Covers coupling, flow, NPSH, pipe velocities, tapping details, flange limits, and pipe sizes.

Provides data on max speed, starting torque, weights, GD^2 values, and component interchangeability.

Safety guidelines for maintenance work, covering hazards and precautions.

Provides a schedule of routine checks and precautions for preventive maintenance.

Step-by-step instructions for disassembling the pump for overhaul.

Detailed instructions for reassembling the pump after overhaul.

Provides a table of general outline dimensions for various pump types.

Lists part codes and descriptions for spare parts.

Includes various cross-sectional drawings of pump assemblies for different models.

Shows an exploded view of the pump with labeled components and part codes.

Table correlating pump breakdown symptoms with potential causes and check points.

Detailed list of potential causes for pump malfunctions and specific check points.

| Brand | KIRLOSKAR |

|---|---|

| Model | 8 UP 200/38 |

| Category | Power Pump |

| Language | English |