Do you have a question about the KIRLOSKAR UP 50/30B and is the answer not in the manual?

Details on pump designation by serial number, model, size and type.

Explains the naming convention for Kirloskar UP pumps, e.g., UP 100/35.

General safety guidelines, hazard awareness, and personnel responsibilities.

Safety precautions for transporting, handling, and storing the pump unit.

Visual inspection upon receipt for damage during transit or handling.

Steps to prepare the pump before installation, including cleaning and lubrication.

Recommendations for optimal pump placement for performance and accessibility.

Specifications for a strong and rigid foundation to absorb vibration and ensure alignment.

Procedures for setting, leveling, and shimming the baseplate.

Steps for grouting the baseplate to ensure stability and prevent shifting.

Methods for aligning pump and driver shafts to prevent vibration and wear.

Guidelines for correct installation of suction and discharge piping to minimize friction.

Essential inspections and preparations before the initial start-up of the pump.

Step-by-step guide for safely starting the pump and driver.

Periodic inspections to perform while the pump is in operation.

Correct steps for shutting down the pump and driving unit.

Information on standard and reversible pump rotation directions.

Details on bearing models, types, and reference numbers for UP pumps.

Instructions for proper care, cleaning, and handling of bearings.

Guidelines for initial lubrication, regreasing intervals, and grease specifications.

Diametrical clearances between impeller and casing wear rings.

Information on single and double entry impellers fitted to different pump types.

Information on packing types, installation, and maintenance for stuffing boxes.

Details on standard and optional pump coupling types.

Guidance on the minimum flow rate required to prevent pump damage.

Explanation of Net Positive Suction Head requirements to prevent cavitation.

Guidelines for maintaining optimal flow velocities in suction and delivery pipes.

Specifications for various tapping points like air vent, priming, and drain connections.

Allowable forces and moments that can be applied to pump flanges.

Table listing nominal suction and delivery bore sizes for different pump types.

Data on maximum allowable operating speed and water fill capacity for each pump.

Graph illustrating starting torque requirements under different operating conditions.

Table of approximate net weights and rotational inertia (GD^2) for pump models.

Table showing interchangeability of various pump components across models.

Safety and environmental hazard instructions for maintenance work.

Periodic maintenance tasks and checks for weekly, monthly, and yearly intervals.

Step-by-step guide for dismantling the pump for overhaul.

Step-by-step guide for reassembling the pump after overhaul.

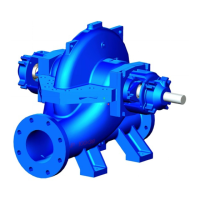

Diagrams showing the internal components of soft packed pumps.

Diagrams showing the internal components of mechanical seal pumps.

An exploded diagram illustrating all pump components and their assembly.

Details on pump designation by serial number, model, size and type.

Explains the naming convention for Kirloskar UP pumps, e.g., UP 100/35.

General safety guidelines, hazard awareness, and personnel responsibilities.

Safety precautions for transporting, handling, and storing the pump unit.

Visual inspection upon receipt for damage during transit or handling.

Steps to prepare the pump before installation, including cleaning and lubrication.

Recommendations for optimal pump placement for performance and accessibility.

Specifications for a strong and rigid foundation to absorb vibration and ensure alignment.

Procedures for setting, leveling, and shimming the baseplate.

Steps for grouting the baseplate to ensure stability and prevent shifting.

Methods for aligning pump and driver shafts to prevent vibration and wear.

Guidelines for correct installation of suction and discharge piping to minimize friction.

Essential inspections and preparations before the initial start-up of the pump.

Step-by-step guide for safely starting the pump and driver.

Periodic inspections to perform while the pump is in operation.

Correct steps for shutting down the pump and driving unit.

Information on standard and reversible pump rotation directions.

Details on bearing models, types, and reference numbers for UP pumps.

Instructions for proper care, cleaning, and handling of bearings.

Guidelines for initial lubrication, regreasing intervals, and grease specifications.

Diametrical clearances between impeller and casing wear rings.

Information on single and double entry impellers fitted to different pump types.

Information on packing types, installation, and maintenance for stuffing boxes.

Details on standard and optional pump coupling types.

Guidance on the minimum flow rate required to prevent pump damage.

Explanation of Net Positive Suction Head requirements to prevent cavitation.

Guidelines for maintaining optimal flow velocities in suction and delivery pipes.

Specifications for various tapping points like air vent, priming, and drain connections.

Allowable forces and moments that can be applied to pump flanges.

Table listing nominal suction and delivery bore sizes for different pump types.

Data on maximum allowable operating speed and water fill capacity for each pump.

Graph illustrating starting torque requirements under different operating conditions.

Table of approximate net weights and rotational inertia (GD^2) for pump models.

Table showing interchangeability of various pump components across models.

Safety and environmental hazard instructions for maintenance work.

Periodic maintenance tasks and checks for weekly, monthly, and yearly intervals.

Step-by-step guide for dismantling the pump for overhaul.

Step-by-step guide for reassembling the pump after overhaul.

Diagrams showing the internal components of soft packed pumps.

Diagrams showing the internal components of mechanical seal pumps.

An exploded diagram illustrating all pump components and their assembly.

| Brand | KIRLOSKAR |

|---|---|

| Model | UP 50/30B |

| Category | Power Pump |

| Language | English |