138

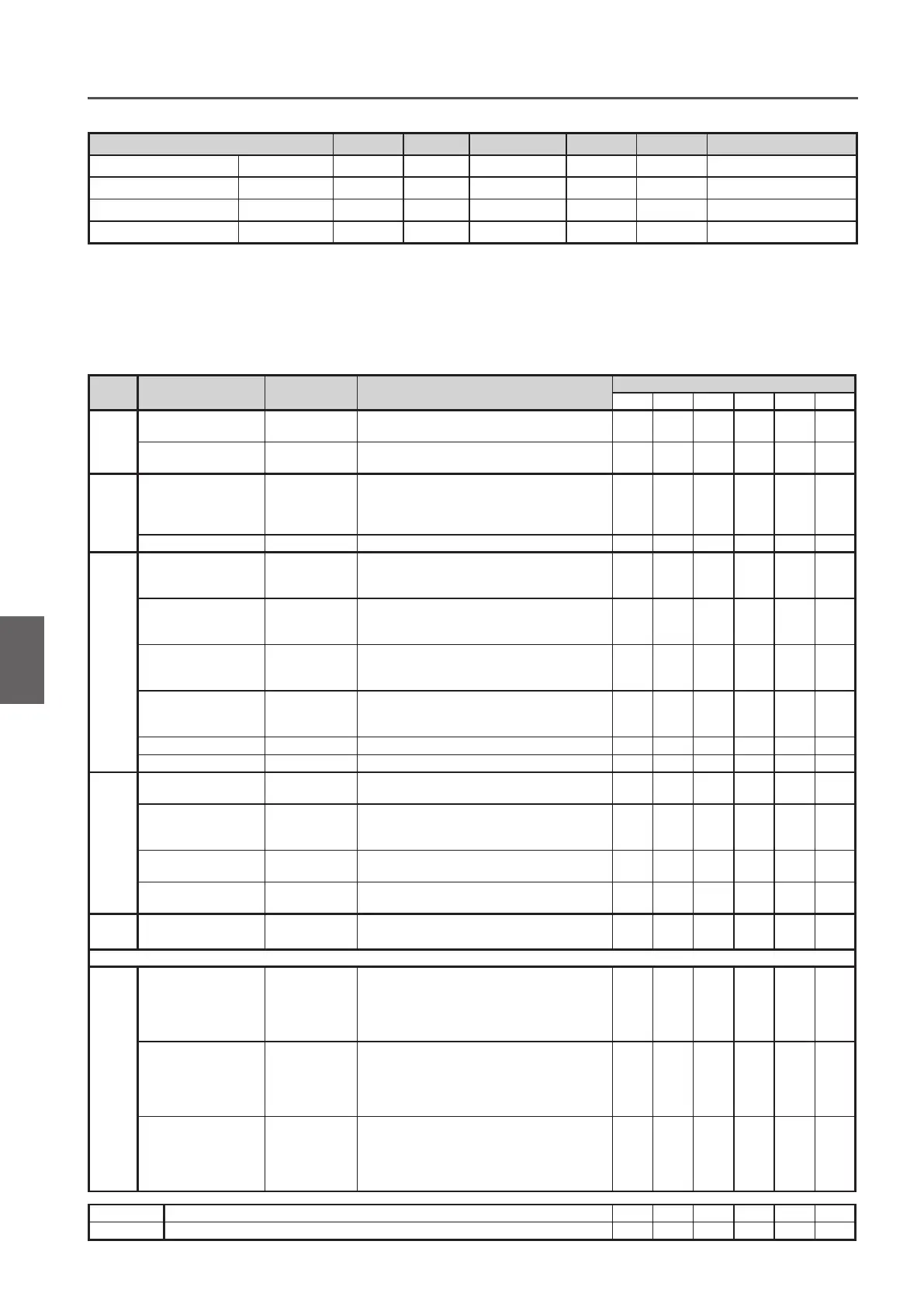

Check Sheet for ER2 Series Electric Chain Hoist Periodic Inspection (continued)

Appendix

■

Motorized Trolley MR2 Periodic Inspection

■

Check result :

○

Good,

△

To be replaced (adjusted) next inspection,

×

Bad, Needs replacement (adjustment)

Category

Check item Check method Criteria

Inspection date/result

/ / / / / /

Preceding

inspection

Daily inspection

Check the

execution

When performing periodic inspection, also perform

the daily inspection.

Frequent inspection

Check the

execution

When performing periodic inspection, also perform

the frequent inspection.

Brake

Appearance Visual inspection

• To have no deformation, aw and damage on the

brake drum and motor cover

• To have no deformation, aw and damage on

brake spring

Brake Pad Measurement Abrasion to be less than limit value

Body size component

Wheel

Visual inspection/

inspection by

measurement

• To have apparent deformation and damage

• Abrasion of outer diameter to be less than limit

value

Side roller

Visual inspection/

inspection by

measurement

• To have no apparent deformation and damage

• Abrasion of outer diameter to be less than limit

value

Lifting shaft

Visual inspection/

inspection by

measurement

• To have no apparent deformation and damage

• Abrasion of outer diameter to be less than limit

value

Suspender

Visual inspection/

inspection by

measurement

• To have no apparent deformation and damage

• Abrasion of outer diameter to be less than limit

value

Gear frame packing Visual inspection

• To have no damage, breakage and grease leakage.

Gears, motor shaft Visual inspection

• To have no apparent abrasion, deformation and damage

Travel Rail

Rail surface Visual inspection

• To have no attachment of paint, oil and foreign matter

• To have no dust and powder due to abrasion

Deformation, abrasion

Visual inspection/

inspection by

measurement

• To have no deformation of beam ange such as

twist and shear drop

• To have no exceeding abrasion of rail surface

Rail xing bolt Visual inspection

To be mounted securely without looseness and

come-off

Stopper Visual inspection

To be mounted securely without looseness and

come-off at the rail end

Relay

cable

Appearance Visual inspection

To be connected securely without deformation and

damage

Refer to check table of electric chain hoist ER2 for electrical parts, push button switch, power feeding and electrical characteristics.

Function/performance

Operational check

Traveling operation

with a capacity

Visual inspection/

inspection by

measurement

Perform inspection of the items on function/performance

of daily inspection with no load, and then perform the

inspection of the same items with a capacity.

• To travel smoothly without serpentine motion and

vibration

Brake

Traveling operation

with a capacity

Visual inspection/

inspection by

measurement

• Stopping distance of traveling to be within 10 %

of the traveling distance, when no swinging of a

load

Strange noise

Traveling operation

with a capacity

Visual inspection/

inspection by

measurement

• To have no irregular rotating noise

• To have no motor hamming or scraping noise of a

brake

Executed by Inspector

Checked by Maintenance Engineer

A

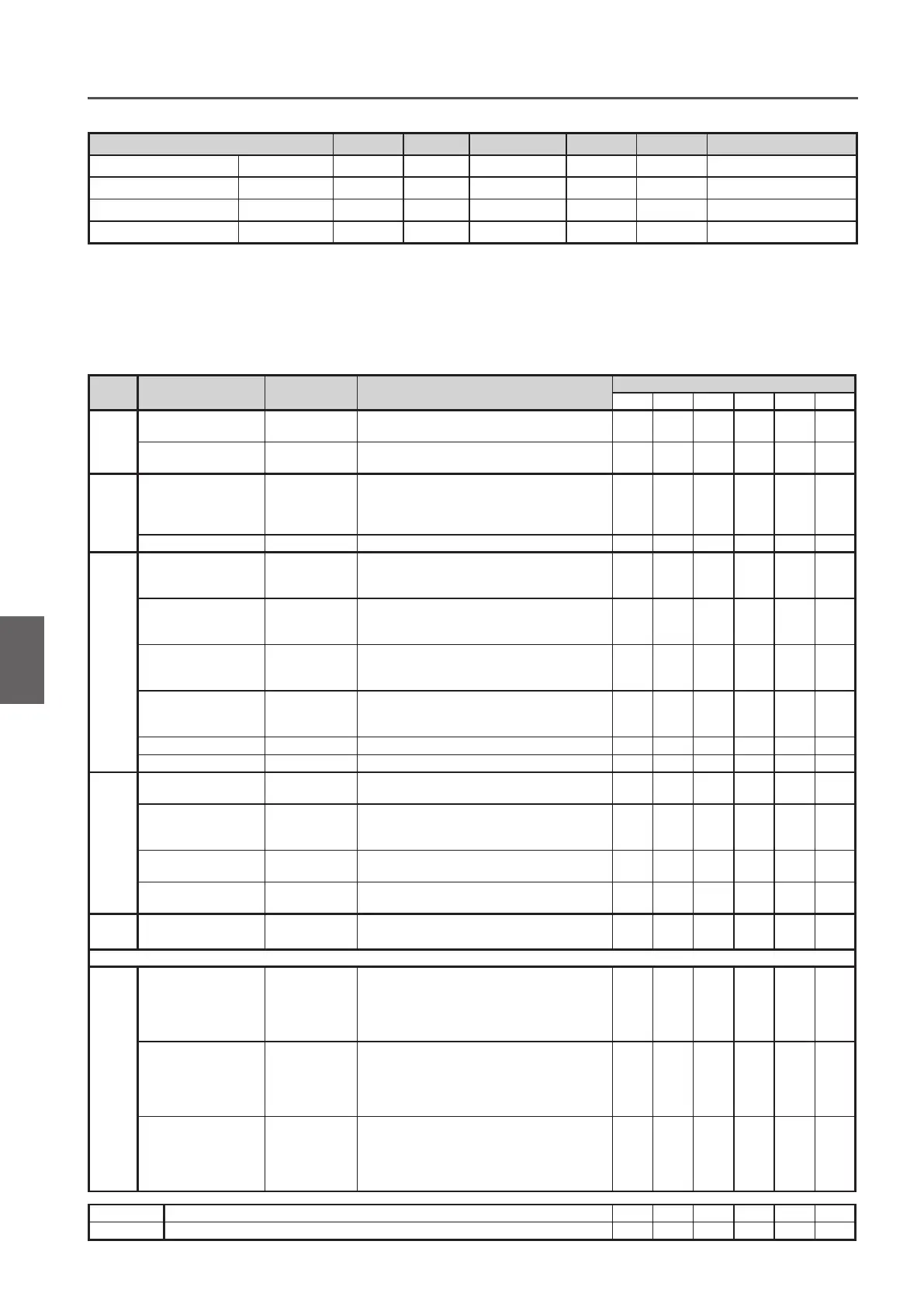

Check Sheet for ER2 Series Electric Chain Hoist Periodic Inspection

Code Capacity Lot No.

Your CTRL No.

Installation date

Location

Inspection Certification valid thru

Electric Chain Hoist ER2

Motorized Trolley MR2

Geared Trolley

TS2 (TSG)

Plain Trolley

TS2 (TSP)

Loading...

Loading...