28

ۣૐ ۞ইૐҴૐ ೠҴসӏѺ ಿ҃మ

5.7 Preparing the Wall

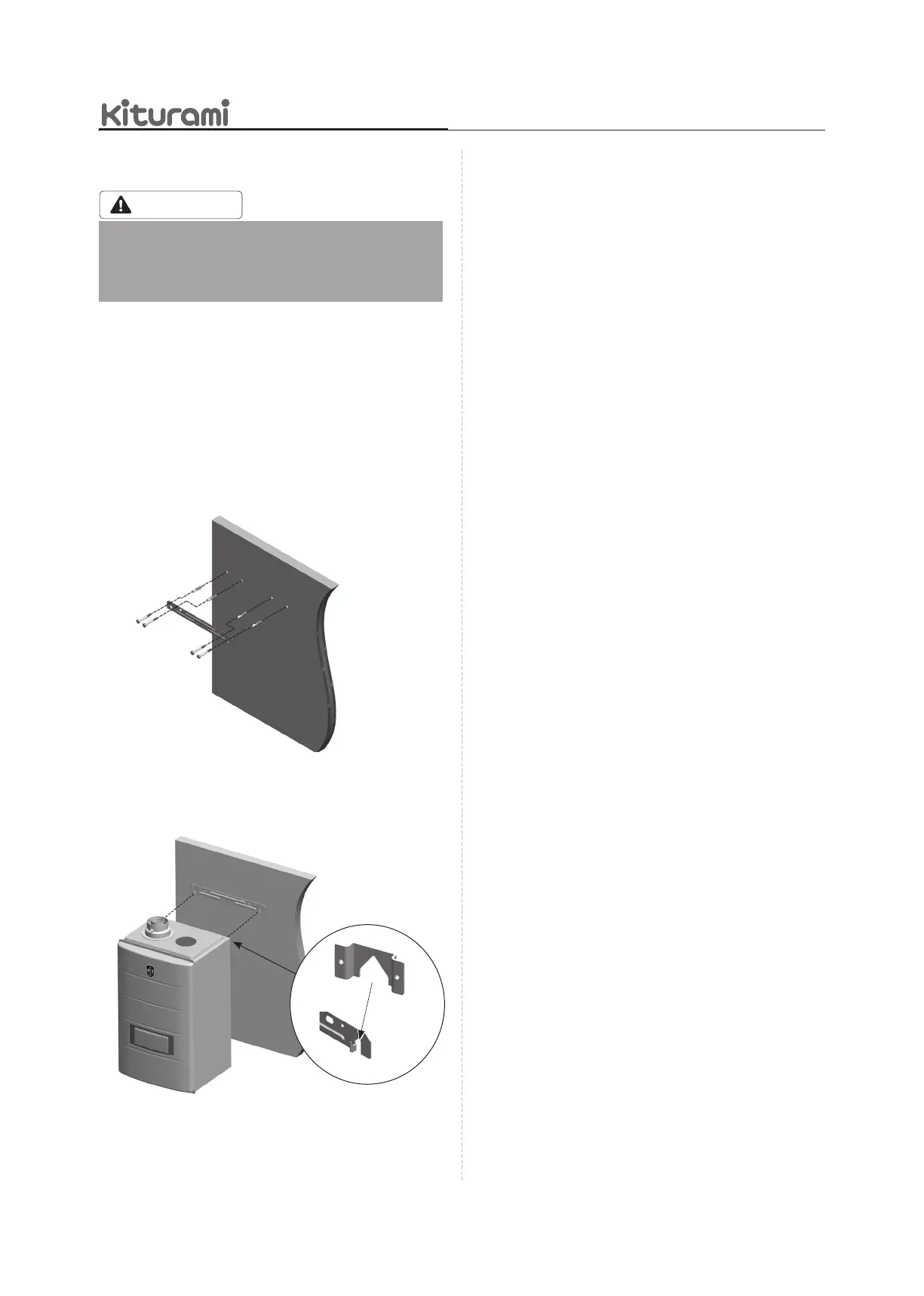

▪Afterconsideringthelocationpositiontoensuringitislevel

bothhorizontallyandvertically.

▪PleaserefertothetemplatebeforeinstallingtheCombi

boiler.

•Attachthetemplateexactlytothelocationwhereyouwantto

installtheappliance.

•Drill12mm(0.47inch)4holesatthepositionoftemplate

bracketwhichisappropriateplaceforinstallingtheheater.

•Afterfouranchorboltsinsertedintheholes,mountthewall

bracket.

CAUTION

Theboilerisheavy.Alwayslifttheunitwithassistance.

Becarefulnottodroptheboilerwhileliftingorhandlingit

toavoidbodilyinjuryordamagetotheunit.

5.8 Heating System Filling and Pressurizing

▪Whenconnectingthespaceheatingsystem,followthese

guidelines:

-Tightentheconnectionvalveswithcaretoavoiddamage.

-Testtheboilerforproperspaceheatingowandinspectfor

leaks.

▪Allingpointconnectionislocatedonthebottomsideof

theboiler,rstopenthehandleitandthenwatercomes

intoheatingsidefromDHWside.Atthistime,installermust

conrmproperlypressureinheatingsidetoworking.

Afterthat,primaryinstallinghastodothisoften,sincemight

benotenoughlledwater.

▪Allingloopdoesn’tsuppliedwiththeboiler.

Then,ifyoursiteshouldbeinstalledallingloop,mustbe

installeditwithqualiedtechnicalperson.Also,shouldbe

followedthelocalcodes.

▪Thellingmethodadoptedmustbeinaccordancewith

allrelevantwatersupplyregulationsanduseapproved

equipment.

5.9 DHW System Filling

▪Closeallhotwaterdrawofftaps.

▪Openthecoldwaterinletcock.

▪Slowlyopeneachdrawofftapandclosethemonlywhen

clearwater,freeofbubbles,isvisible.

▪AllDHWcircuits,connections,ttings,etc.shouldbefully

inaccordancewithrelevantstandardsandwatersupply

regulations.

▪Theboiler’smaximumworkingmainspressureis10bars,

thereforeallpipework,connections,ttings,etc.,should

besuitableforpressuresinexcessof10bars.

Apressurereducingvalvemustbettedforpressuresin

excessof10bars.Themanufacturerofanyoutletttings,

suchasashowervalve,mayrequirealowermaximum

pressure.Thepressurereductionmusttakeaccountofall

ttingsconnectedtotheDHWsystem.

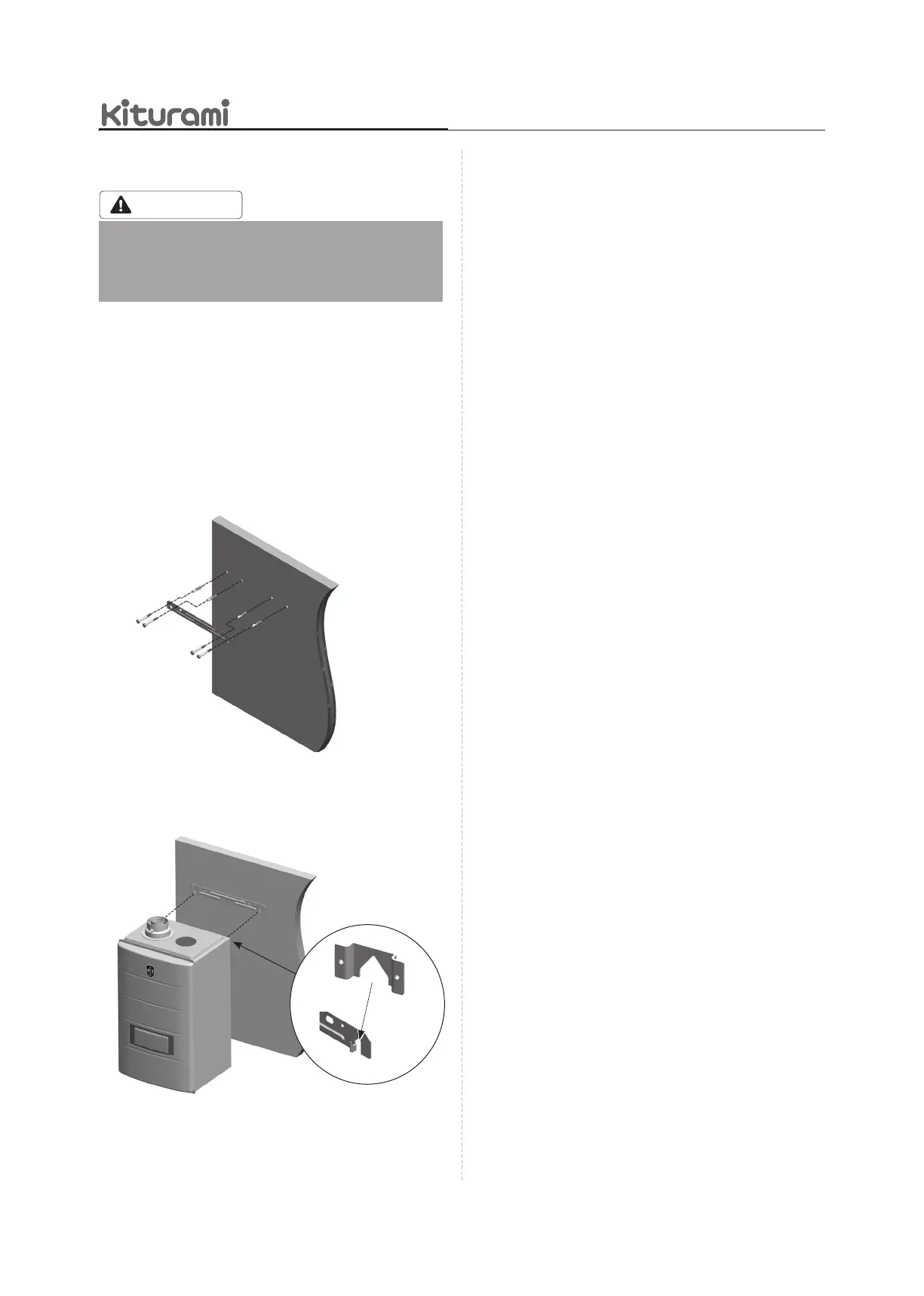

•Afxthewallbracketsecurelytothewall.

Makesurethatitislevelanditcansupporttheweightofthe

Combiboiler.

Loading...

Loading...