DocumentNo.:KE-4025-06 17/50

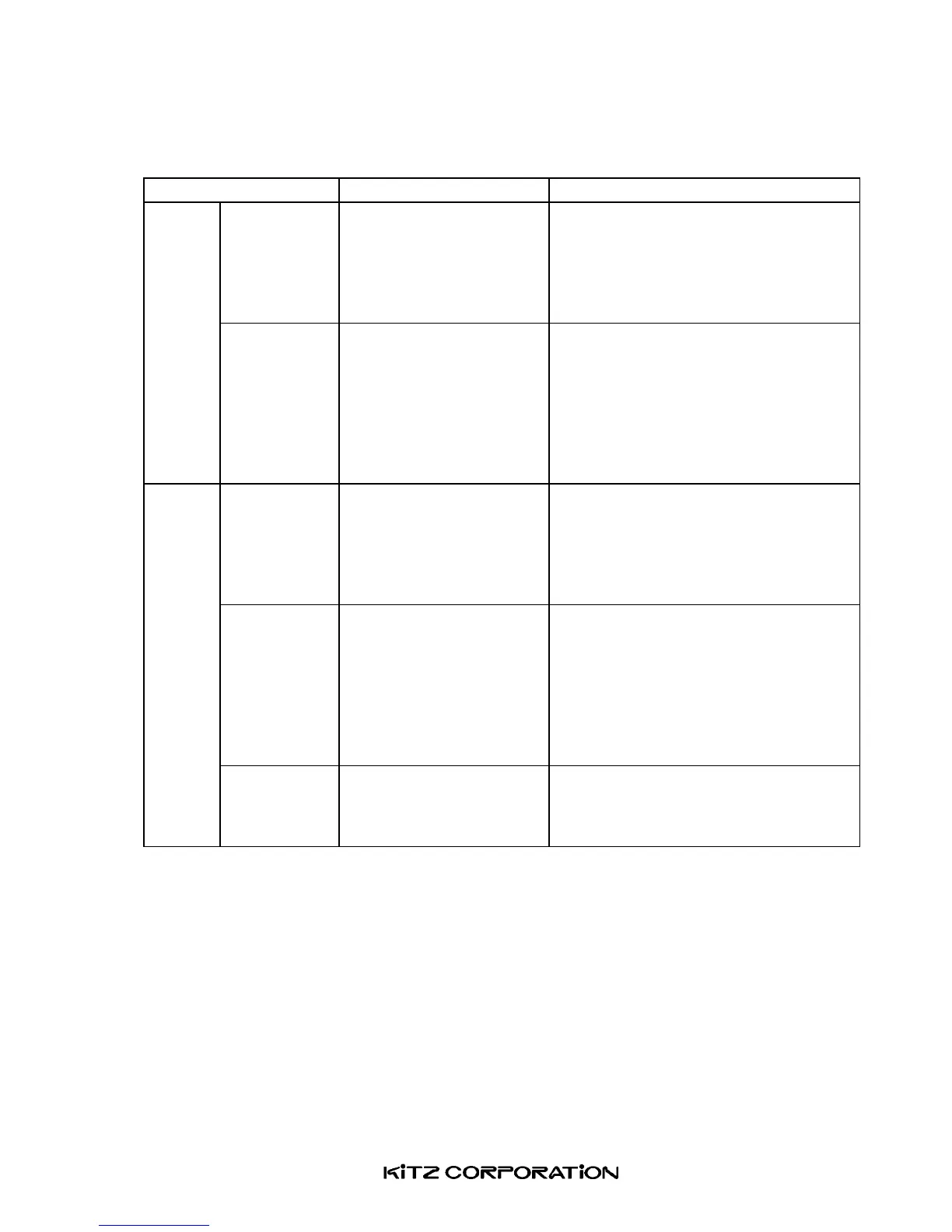

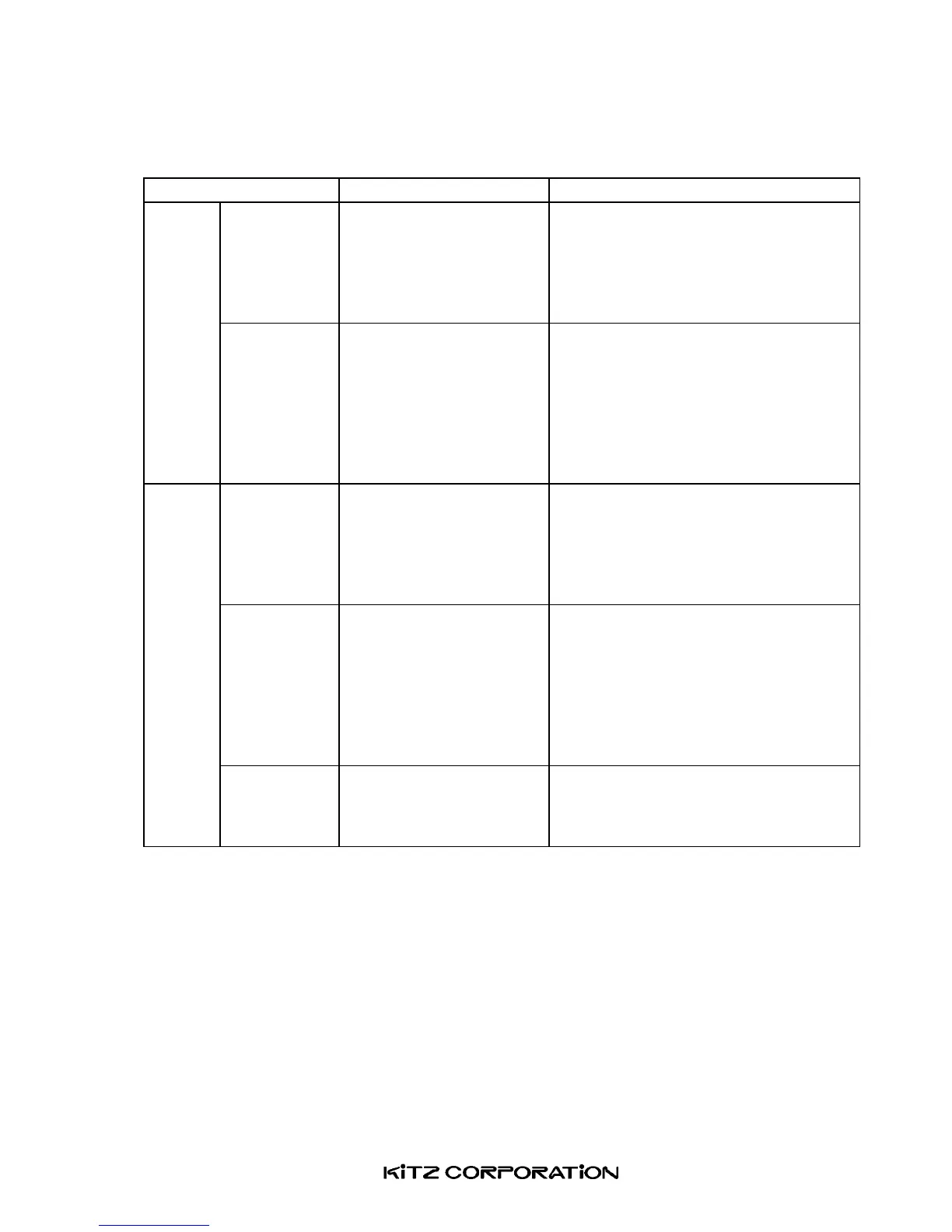

Troubleshootingofthemanualoperationunit

Trouble PossibleCauses RemedialMeasures

Not

automatically

operated

① Operate the valve with

the pin is inserted into

thepinhole.

② The pressure equalizing

valveisopened.

③ Noairissupplied.

① Remove the pin from the pin hole and

insertaplugintoit.

② Closethepressureequalizingvalve.

③ Supplyairtotheactuator.

Automated

operation

The operation

speedisslow.

① Malfunctionofthevalve

② Malfunctionofthe

actuator

③ Airpressureislow.

④ Excessive throttling of

speedcontroller

⑤ Corrosion of internal

parts

① Disassembly/check/cleaning the valve

andreplacementofvalveseats

② Disassembly/replacement of actuator

partsorreplacementoftheactuator

③ Readjustmentofthefilterregulator

④ Readjustmentofthespeedcontroller

⑤ Replacementofthemanualoperationunit

Not manually

operated

① The pin is not inserted

into the pin hole.

② Air is supplied to the

actuator.

③ A pressure equalizing v

alve is closed.

① Insertthepinintothepinholecompletely.

② Stop supplying air to the actuator and

openthepressureequalizingvalve.

③ Openthepressureequalizingvalve.

Thepincannot

beinserted

intothepin

hole.

① Indicator is not adjusted

tothepinhole.

② A pin hole on a worm

wheelandapinholeona

shaftarenotaligned.

③ Foreignobjectsarestuck

onthepin

④ Thepinisdeformed.

① Adjust the indicator to the pin hole

rotatinghandle.

② Adjust the pin hole on the worm wheel

andthepinholeontheshaftbyrotating

thehandlelittlebylittle.

③ Cleanthepin.

④ Replacethepin.

Manual

operation

Impossible to

removethepin

from the pin

hole.

① Thepiniscaughtinthe

internalpart.

② Airpressureissupplied.

① Free the pin from the internal parts by

rotatingthehandlelittlebylittle.

② Stopsupplyingtheair.

Loading...

Loading...