13/31

DocumentNo.:KE-4051-00

1.Beforeinstallation,checkthatthedesignspecificationsoftheproductsatisfyalltheserviceconditions.

2.Removedusts,scalesandotherforeignobjectsfromthevalveendthreadsandtheinsideofthepipe.

3.Checkthethreadtypeandthestandardofvalvethreadswithagauge.Makesurethattherequirednumber

oftheeffectivethreadsisprovided.

4.Toscrewthevalveintothepipe,applyawrenchtothehexagonportionofthevalveendwhichisjoinedwith

apipe.

5.Forinstallationofbronzeorbrassvalves,usetheappropriatetighteningtorqueshowninthetablebelow.

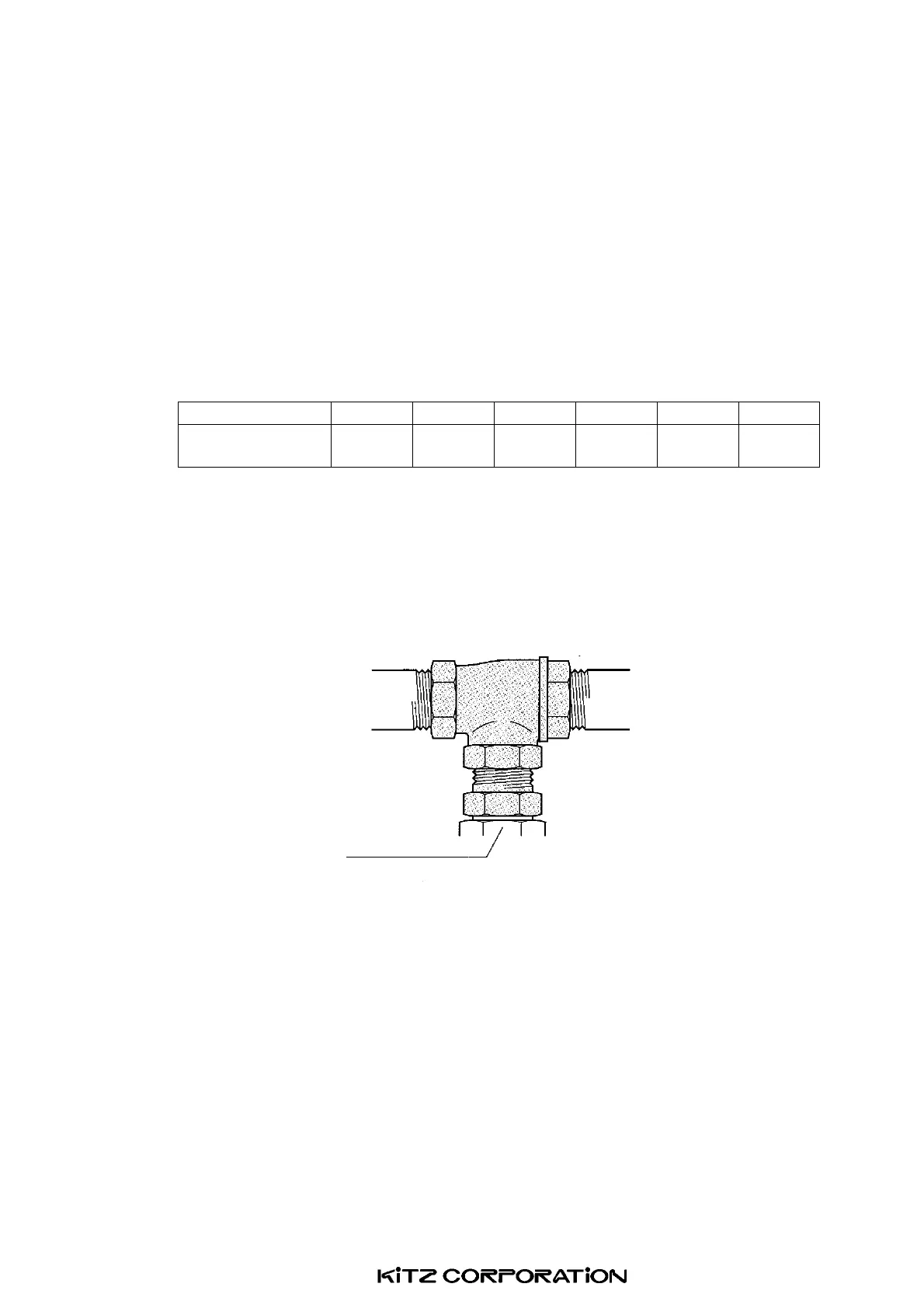

TighteningTorque

ValveSize 1/2 3/4 1 11/4 11/2 2

TighteningTorque

N-m

20to29 39to49 49to59 59to69 69to78 78to88

6.Tothreadedends,applyasealingmaterialsuitabletotheservicefluidandtemperature.

7.Aftercompletingtheinstallationoftheproduct,performflushingwiththevalveinthefullyopenpositionto

removeforeignobjectsfromthepipeline.

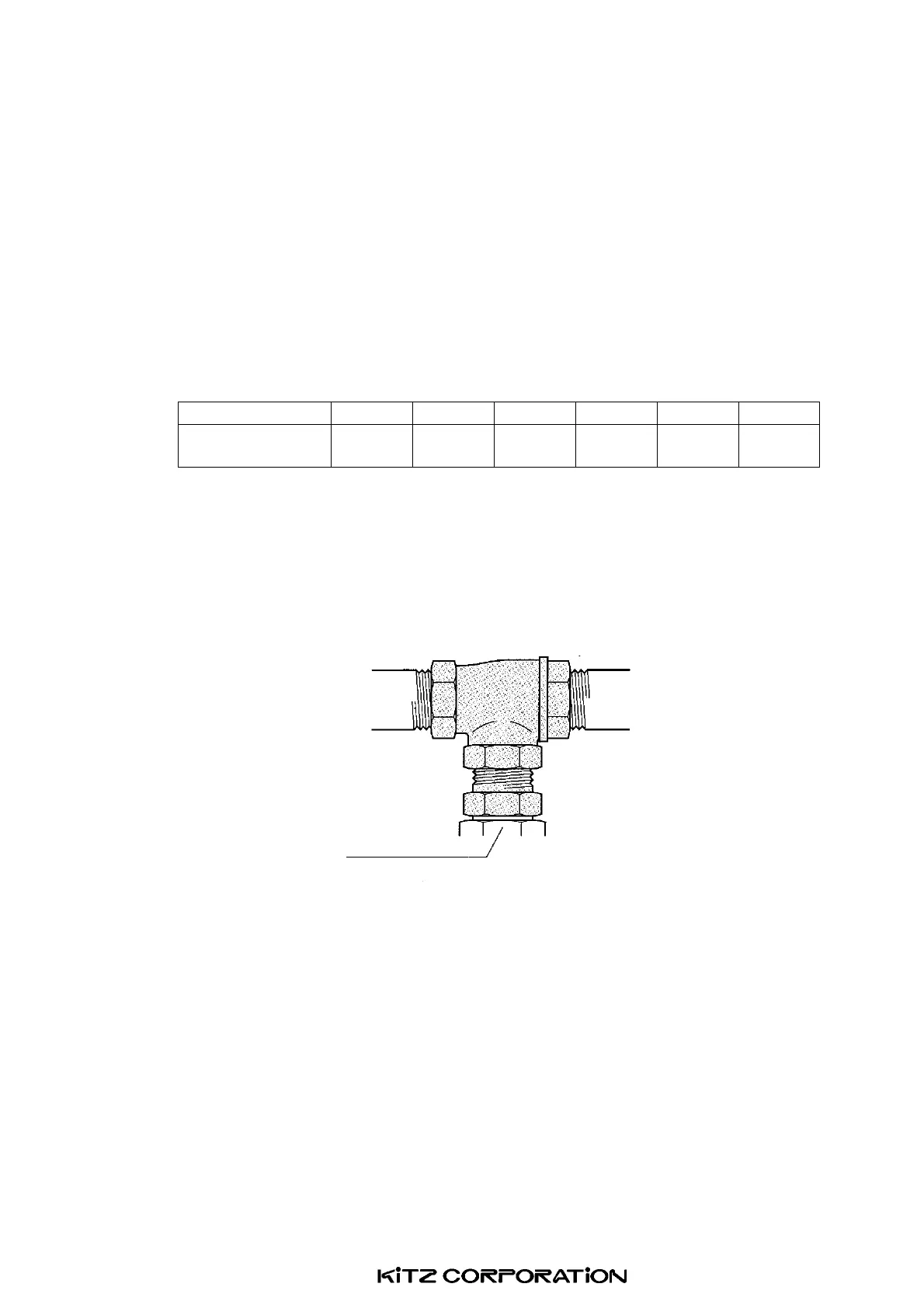

8.UseofaflexibletubetotheCsideisrecommendedforinstallationof3-wayballvalves.

Fig.14

B

C

A

Flexibletube

for3-wayvalve

Loading...

Loading...