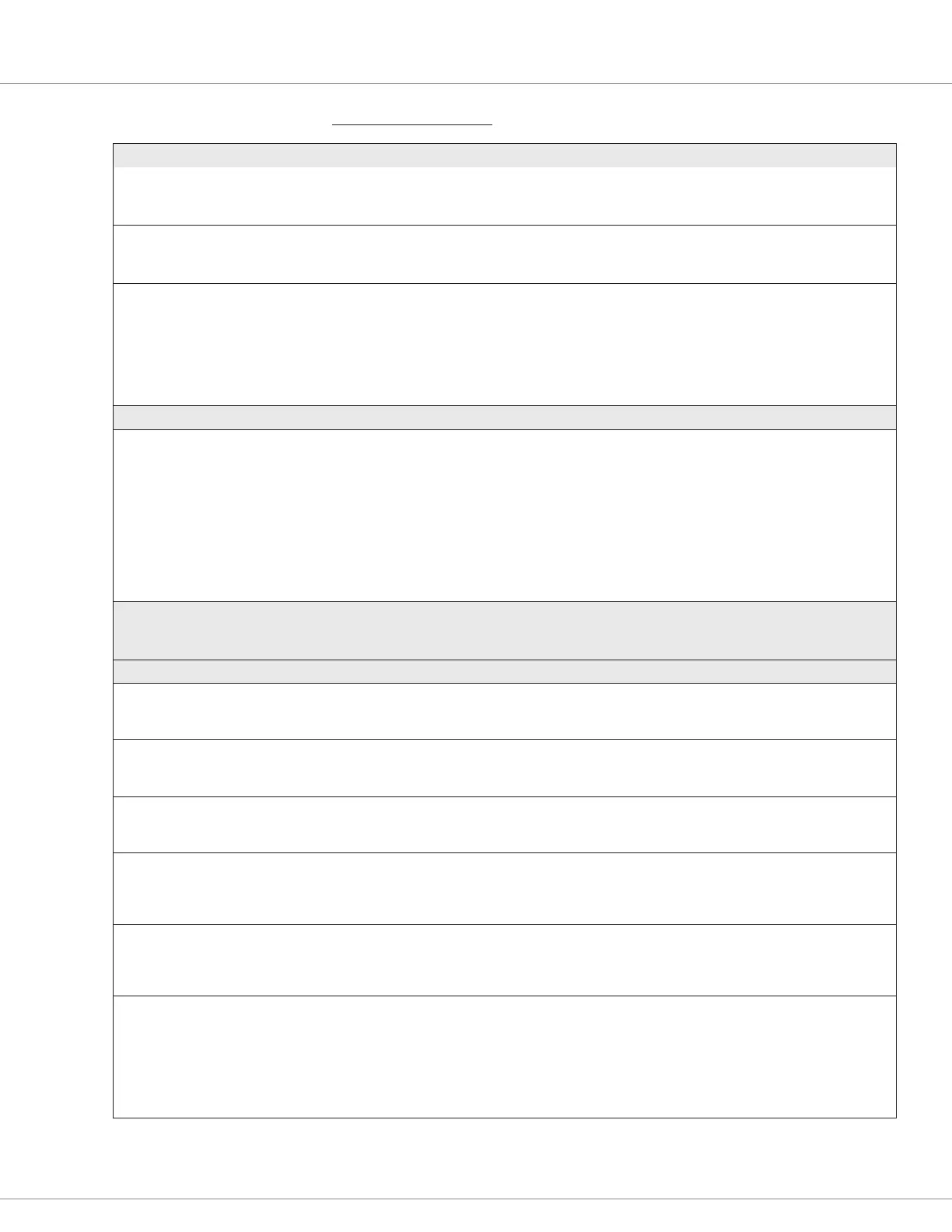

4 — PROGRAMMABLE PARAMETERS

pg. 113

Return to TOC Curtis AC F2-A, F4-A, F6-A Motor Controllers – FOS 4.5 – April 2022

CONTROLLER SETUP — INPUTS MENU, cont’d

PARAMETER ALLOWABLE RANGE DEFAULT DESCRIPTION

Low

analog_input_9_low

0x3301 0x00

0.0 – 30.0V

0 – 3000

0.0V The minimum input voltage before a fault is declared.

This voltage represents the 0% point for the normalized inputs.

High

analog_input_9_high

0x3302 0x00

0.0 – 30.0V

0 – 3000

30.0V The maximum input voltage before a fault is declared.

This voltage is the 100% point for the normalized inputs.

Fault Tolerance

Analog_Input_9_Fault_Tolerance

0x3378 0x00

0.0 – 11.0V

0 – 1100

0.0V Species the voltage threshold above the congured high limit

or below the low limit, exceeding this results in an analog out of

range fault.

For example, if High = 9.6V, Low = 1V and Tolerance = 0.2V, an

input voltage between 1V to 9.6V is mapped to 0–100%.

Voltages above 9.8V (9.6 + 0.2) or below 0.8V (1V – 0.2V) trigger

the fault.

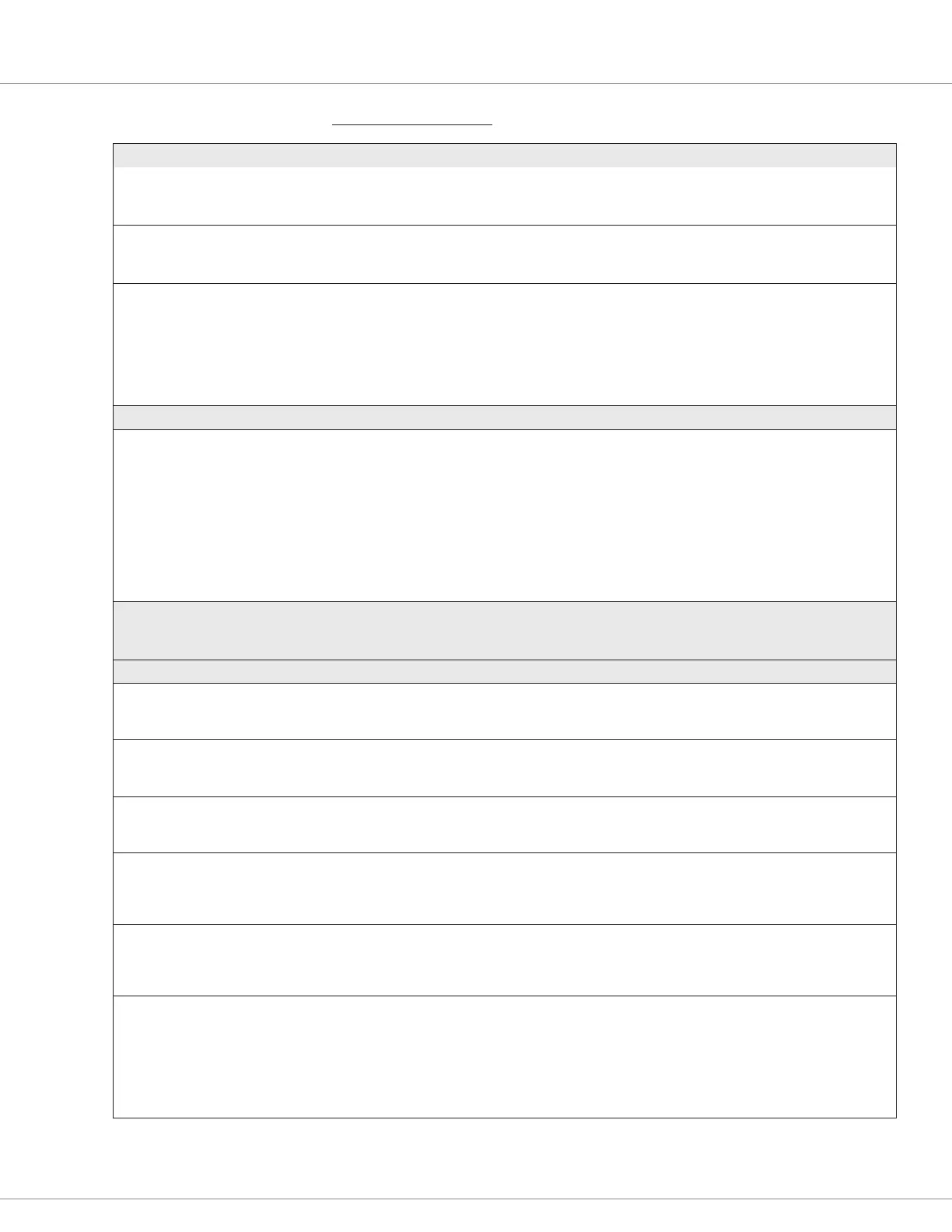

PWM Input 10

PWM Input 10 Type

PWM_Input_10_Type

0x5088 0x00

Enumerated*

0 – 2

*Enumerated Options:

0 – Disabled

1 – Duty Cycle

2 – Frequency

0 Input 10 is a high frequency input for either duty-cycle or frequency

signals. When not using the PWM input options, the input operates

as a switch input. See the signal-chain gure, next page.

0 – The PWM Input is not used, and disables fault checking

on this PWM input. This option, for example, is when this

input is used as a switch input.

1 – The PWM_Input_10_Percent is normalized to the duty

cycle low/high range. Fault check is active.

2 – The PWM_Input_10_Percent is normalized to the

frequency low/high range. Fault check is active.

PWM Input 10 Type = (1) duty cycle or (2) frequency

These PWM Input 10 monitor and parameter items are only visible when options 1 or 2 are selected

These items are visible within the Programmer app, Controller Setup » Inputs » PWM Input 10 menu

PWM Input 10 menu

Duty Cycle

PWM_Input_10_Cycle

0x3B69 0x00

0.0 – 100.0 %

0 – 1000

0.0 %

Read Only

PWM Input 10 duty cycle measurement.

Frequency

PWM_Input_10_Frequency

0x3B67 0x00

0 – 10000

0 – 10000

0 Hz

Read Only

PWM Input frequency measurement.

Percent

PWM_Input_10_Percent

0x3192 0x00

0.0 – 100.0 %

0 – 1000

0.0 %

Read Only

PWM input 10 as a percentage of the congured type (duty cycle,

or frequency). 0% maps to min, 100% maps to max.

Duty Cycle Low

PWM_Input_10_Low_Duty_

Cycle

0x5080 0x00

0 – 100 %

0 – 1000

0 % PWM Input low duty cycle threshold.

Duty Cycle High

PWM_Input_10_High_Duty_

Cycle

0x5081 0x00

0 – 100 %

0 – 1000

100 % PWM Input high duty cycle threshold.

Note: Do not set the high value lower than the corresponding

low value.

Duty Cycle Fault Tolerance

PWM_Input_10_Duty_Cycle_

Fault_Tolerance

0x33AF 0x00

0 – 100 %

0 – 1000

0 % Species the PWM input duty cycle threshold above the

congured high limit or below the low limit. Exceeding this results

in a PWM input out of range fault.

For example, if High = 96%, Low = 1% and Tolerance = 0.2%, a

PWM input duty cycle between 1% to 96% is mapped to 0-100%.

PWM input above 96.2% (96 + 0.2) or below 0.8% (1% – 0.2%)

triggers the fault.

Quick Links:

Voltage rottle p.166

3-Wire rottle p.165

2-Wire rottle p.165

Fig. 13 p.17

Loading...

Loading...