4 — PROGRAMMABLE PARAMETERS

Curtis AC F2-A, F4-A, F6-A Motor Controllers – FOS 4.5 – April 2022 Return to TOC

pg. 138

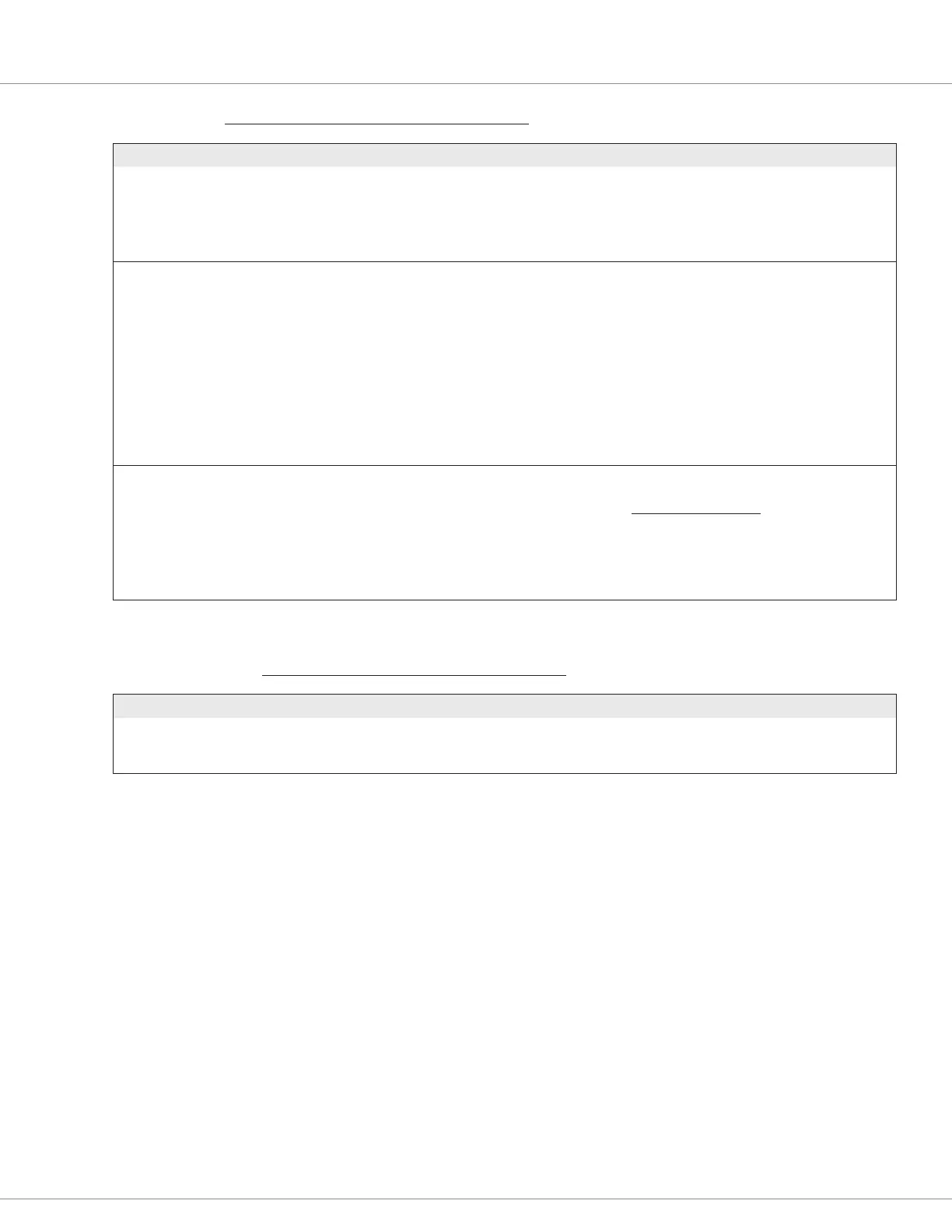

MOTOR SETUP/QUADRATURE ENCODER — ENCODER FAULT SETUP MENU

PARAMETER ALLOWABLE RANGE DEFAULT DESCRIPTION

Fault Detection Enable

Encoder_Fault_Detection_

Enable

0x34E3 0x00

On/Off

On/Off

On Setting this parameter to On enables the encoder fault

checking. The three fault conditions checked are:

Encoder Fault (fault code 36).

Stall Detected (fault code 73).

Encoder Pulse Error (fault code 88).

Encoder Pulse Fault Detect

Time

Encoder_Pulse_Fault_Detect_

Time

0x34E5 0x00

0.0 – 3.0 s

0 – 94

0.5 sec Denes the minimum time it takes for the controller, while the

vehicle is in motion, to detect that the encoder and the Encoder

Steps parameter do not match. When the Encoder Steps setup is

incorrect, the motor controller cannot properly calculate the AC

motor eld orientation. The loss of eld orientation can cause the

motor to spin up toward full speed once any throttle is applied.

Applying the throttle and then releasing it, while the drive current

is signicant and the motor is still accelerating, sets this timer.

Note that the motor can spin to high rpms for several seconds

before conditions allow the controller to detect a fault.

The Encoder Pulse Error (fault code 88) is set when this fault occurs.

Setting the parameter to zero will disable this fault detection.

Fault Stall Time

Enc_Fault_Stall_Time

0x34E2 0x00

0 – 10 s

0 – 5000

5 sec Sets a timer when no motor encoder movement is detected. If no

motor movement (encoder pulse) is detected for the programmed

Fault Stall Time with high current applied a Stall Detected fault is

issued (fault code 73).

For example, when driving up a ramp and the vehicle ‘stalls’

because it is under-powered or overloaded (driver applying full

throttle), or if driven into an immovable object, these types of

conditions will set this fault.

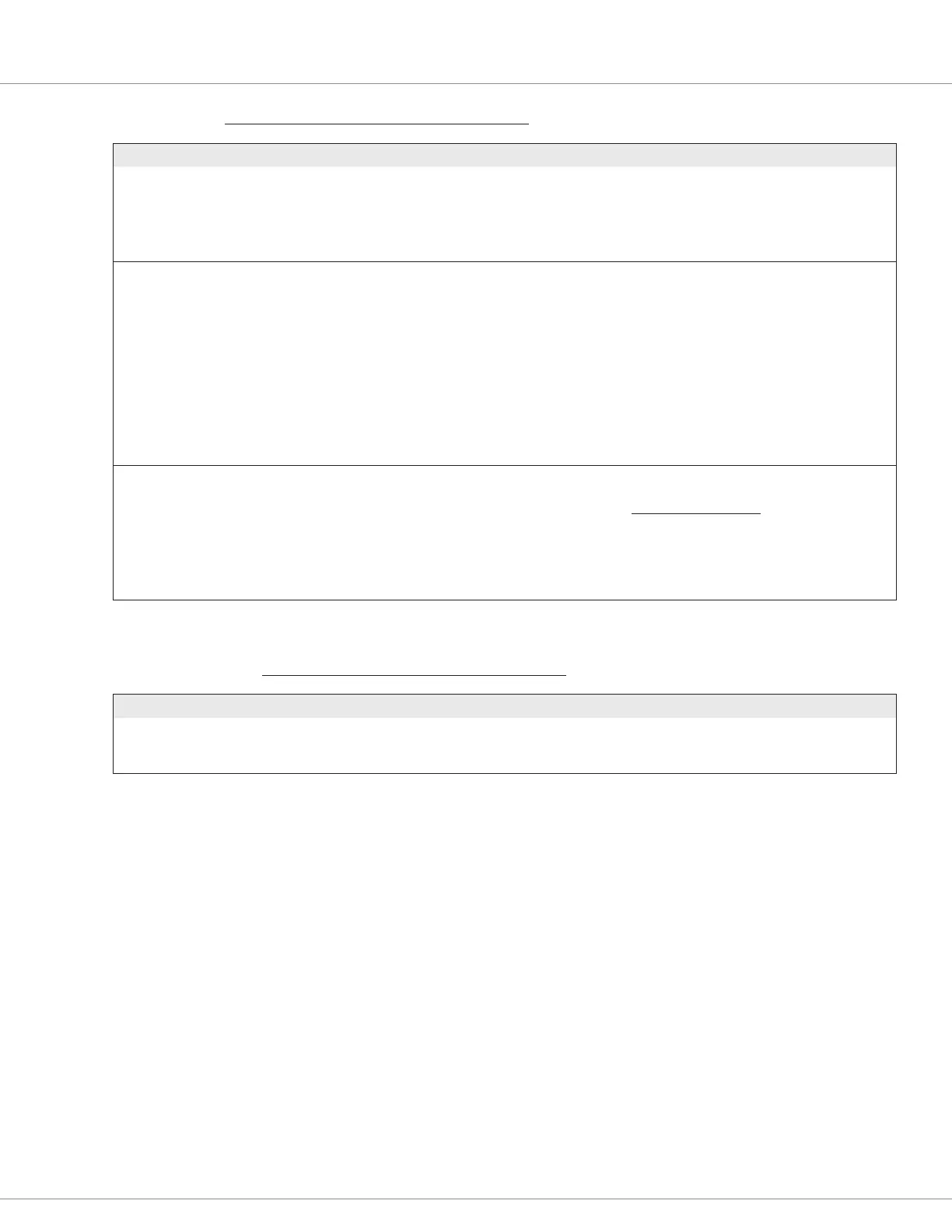

MOTOR SETUP/QUADRATURE ENCODER — SPEED FILTER MENU

PARAMETER ALLOWABLE RANGE DEFAULT DESCRIPTION

Speed Filter Frequency

Speed_Filter_Frequency

0x3224 0x00

0.1 – 250 Hz

0.1 – 250

30.0 Hz Cutoff frequency for speed ltering. Note, this value is now in

hertz, when updating from old versions you may need to divide by

2pi (3.14159) to get the exact performance.

Loading...

Loading...