7 — DIAGNOSTICS AND TROUBLESHOOTING

pg. 239

Return to TOC Curtis AC F2-A, F4-A, F6-A Motor Controllers – FOS 4.5 – April 2022

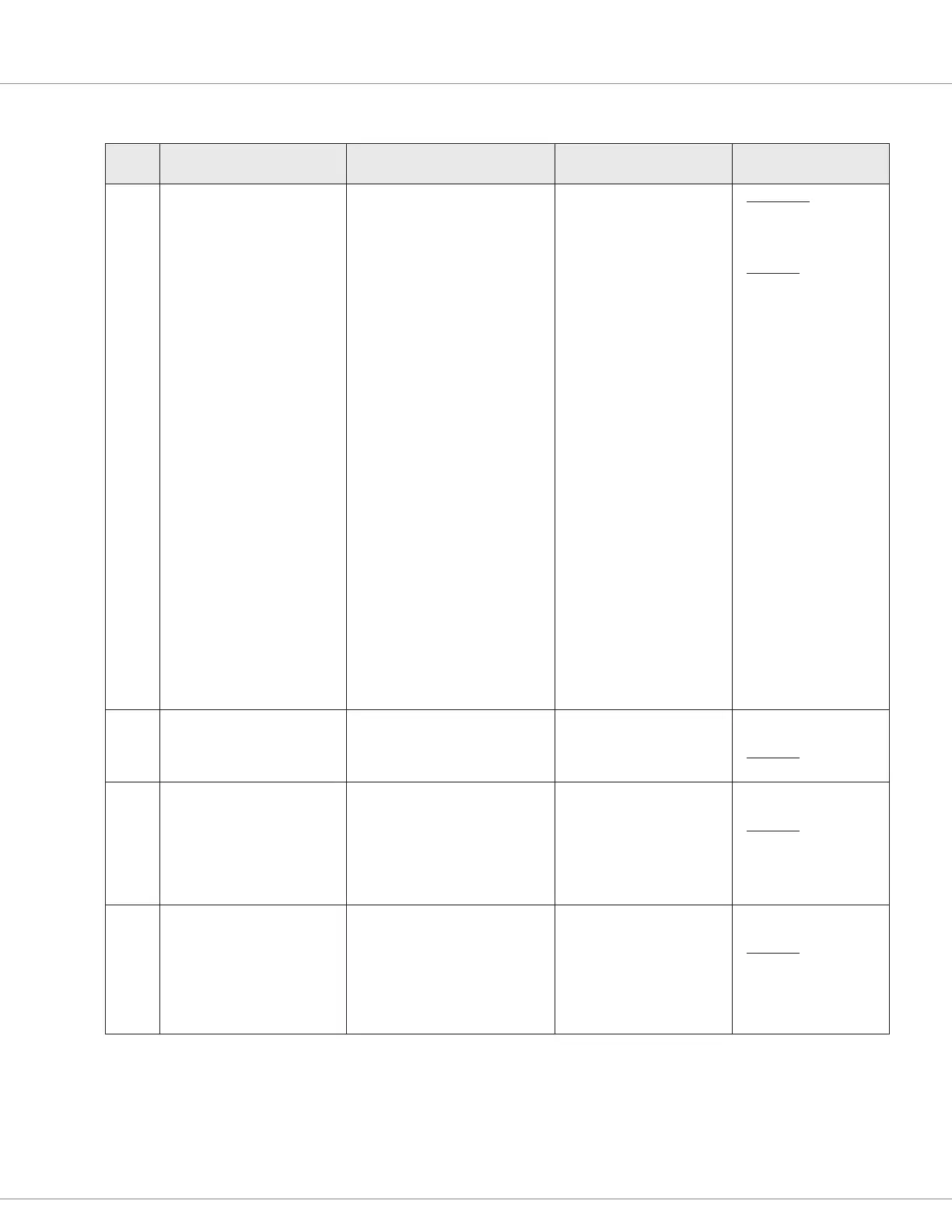

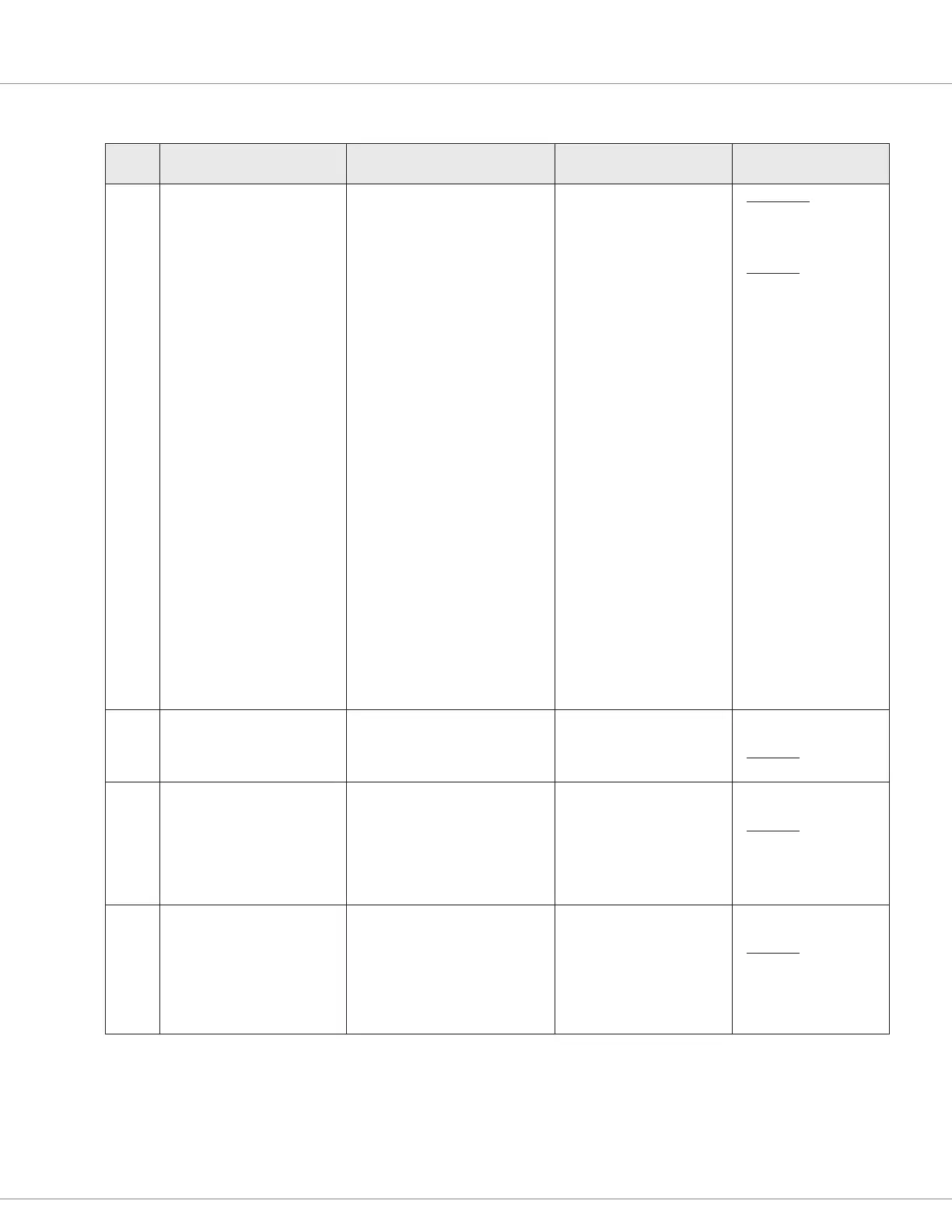

Table 24 Fault Code Troubleshooting Chart, cont’d

FLASH

CODE

FAULT NAME

(Curtis Integrated Toolkit™)

POSSIBLE CAUSES SET/CLEAR CONDITIONS FAULT ACTIONS

12-5

0xC5

PWM Input 10 Out of Range

PWM_Input_10_Out_Of_Range

0x2629

Fault Type(s):

1 = The input is disconnected.

2 = The measured input

frequency is below the

( PWM_Input_10_Low_

Frequency ) – ( PWM_

Input_10_Frequency_

Fault_Tolerance ).

3 = The measured input

frequency is above the

( PWM_Input_10_High_

Frequency ) + ( PWM_

Input_10_Frequency_Fault_

Tolerance ).

4 = The measured duty cycle is

below set limits,

( PWM_Input_10_Low_

Duty_Cycle ) – ( PWM_

Input_10_Duty_Cycle_

Fault_Tolerance ).

5 = The measured duty cycle is

above set limits,

( PWM_Input_10_High_

Duty_Cycle ) + ( PWM_

Input_10_Duty_Cycle_

Fault_Tolerance ).

1. This fault diagnostic execution

cycles every 4msec.

The input is considered

disconnected if no PWM signal

occurs for 16msec or the

measurements are not updated

every 16msec.

2. Mistuned parameters.

3. Faulty wiring.

Set: The input frequency and/or

duty-cycle on Input 10 exceeds

the congured limits set by

PWM_Input_10 _x_ Duty_Cycle

and PWM_Input_10_x_

Frequency , where x = {Low,

High}.

Clear: Reset controller.

Fault Action:

None, unless a fault action

is programmed in VCL.

Dual Drive

Same, both motors

12-7

0xC7

Analog 31 Out of Range

Analog_31_Out_Of_Range

0x2106

See Analog 1 Out of Range. See Analog 1 Out of Range. See Analog 1 Out of Range.

Dual Drive

Same, both motors

12-8

0xC8

Invalid_CAN_Port

Invalid_CAN_Port

0x2107

Fault Type(s):

The condition is checked at

start-up, (i.e. during the dual

drive initialization).

1. Mistuned Dual Drive CAN

parameters.

2. Conicting CAN Node IDs for Dual

Drive.

Set: This fault is triggered

when the Dual CAN Port

(DualMotorCanPort) parameter

is set to a CAN port that does

not exist on a controller setup

for Dual Drive.

Clear: Reset controller.

NO ACTION

Dual Drive

Same, both motors

12-9

0xC9

VCL Watchdog

VCL_Watchdog

0x2108

See the associated VCL Functions,

• Set_Watchdog_Timeout( ).

• Set_Watchdog_Fault_Action( ).

• Kick_Watchdog( ).

The fault actions can be dened by

the User/OEM in the application-

specic VCL software.

Set: The time interval of the

VCL watchdog (WD#) exceeded

the timeout value.

Clear: Kick_Watchdog( ).

Start and reset the specied

watchdog timer.

NO ACTION

Dual Drive

Same, both motors

Loading...

Loading...