TP-6984 5/17a16 Section 1 Installation

1.7.3 Connecting the Fuel Supply

The dimension drawing in Section 3 shows the location

of the fuel inlet connection. Have the fuel supplier install

rigid gas piping and a manual fuel shut-off valve. The

fuel supply line should line up with the generator set fuel

inlet and end about 12 inches away to allow connection

with a section of flexible fuel line. Use flexible sections to

prevent fuel line breakage caused by vibration.

Note: Do not bend the flexible fuel line to make up for

misalignment of the fuel supply line and the

generator set fuel inlet.

Apply pipe sealant that is approved for fuel connections.

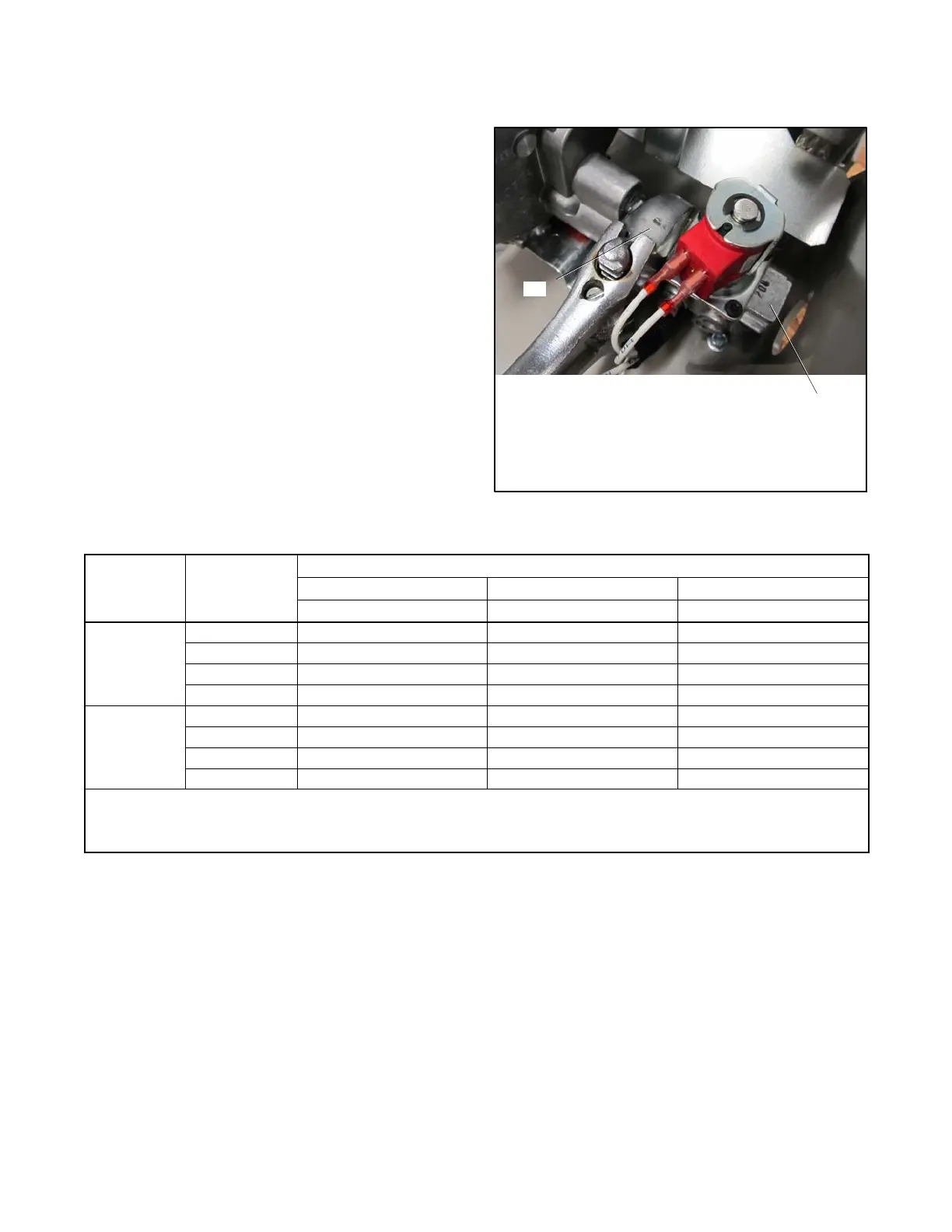

Hold the fuel solenoid valve with a wrench when

tightening the fuel connections.

Note: Do not hold the fuel solenoid valve coil when

tightening the fuel connections. See Figure 1-8

for the recommended wrench locations.

Open the manual fuel valves and test all fuel

connections using soapy water. If a leak is found, close

the fuel valves, clean the fittings, and apply fresh

sealant. Check for fuel leaks again with the generator

set running.

Protect all fuel lines from machinery or equipment

contact, adverse weather conditions, and environmental

damage.

2

1. Hold valve with wrench on flats of valve body

2. Alternate wrench location

Note: Do NOT hold the valve coil when tightening connections.

1

Figure 1-8 Holding Fuel Valve to Tighten Fuel

Connections

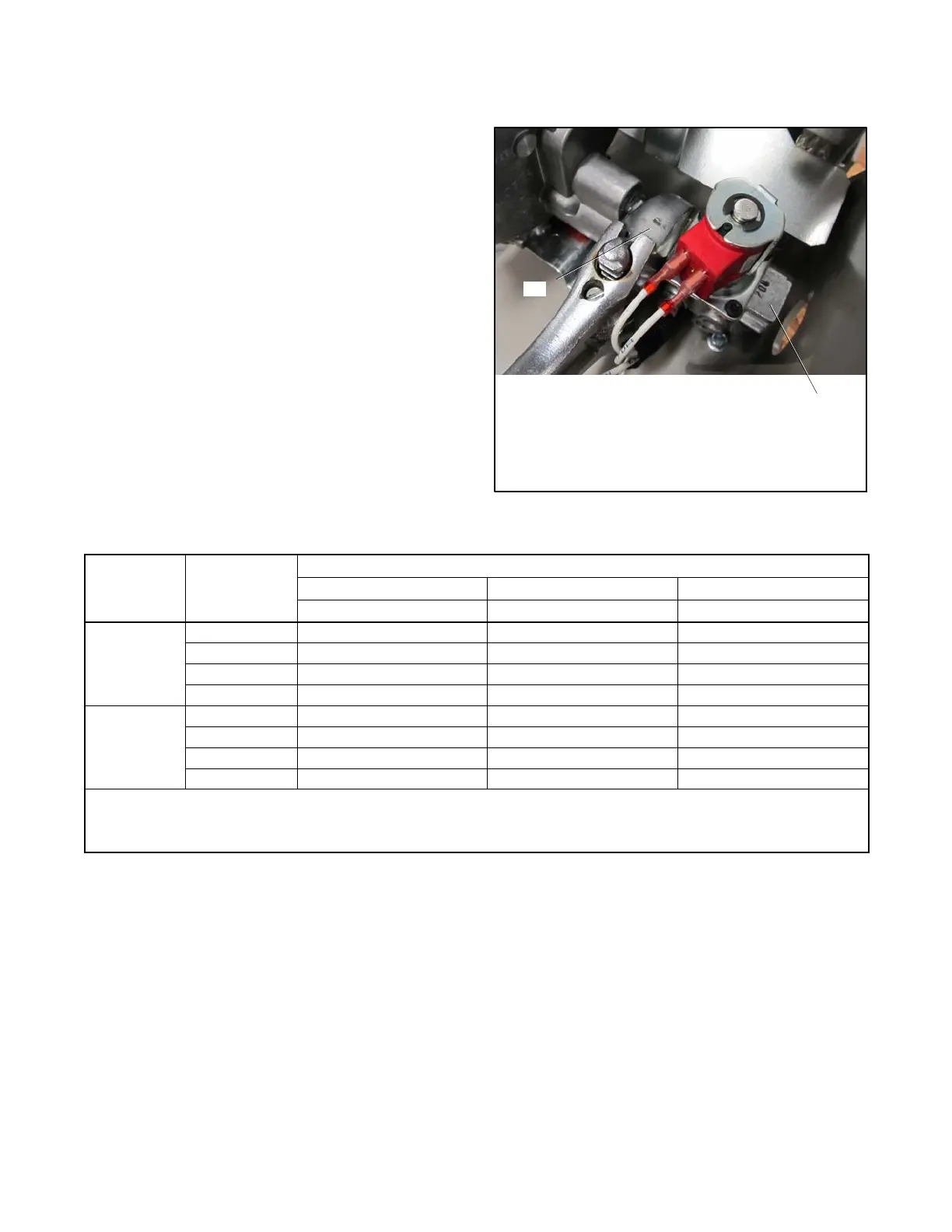

Fuel Type % Load

Fuel Consumption, m

3

/hr. (cfh)

8RESV/RESVL 10RESV/RESVL 12RESV/RESVL

60 Hz 60 Hz 60 Hz

Natural Gas

100% 3.9 (136) 5.1 (179) 6.1 (216)

75% 2.7 (95) 4.1 (145) 4.5 (160)

50% 2.0 (69) 3.4 (120) 3.6 (128)

25% 1.5 (53) 2.7 (97) 2.8 (99)

LPG

100% 1.7 (59) 2.5 (89) 2.9 (103)

75% 1.3 (45) 2.0 (69) 2.2 (76)

50% 1.0 (36) 1.5 (52) 1.6 (57)

25% .75 (26) 1.1 (39) 1.2 (42)

LPG conversion factors:

8.58 ft.

3

=1lb.

0.535 m

3

=1kg

36.39 ft.

3

= 1 gal.

Nominal fuel rating:

Natural gas: 37 MJ/m

3

(1000 Btu/ft.

3

)

LPG: 93 MJ/m

3

(2500 Btu/ft.

3

)

Figure 1-9 Fuel Consumption

Loading...

Loading...