Disassembly/Inspection and Service

126 62 690 05 Rev. HKohlerEngines.com

M Electrical Connector N Evap Line O

High Pressure Fuel

Line Connector

P

Oil Cooler (Engine

Mounted)

Q Oil Filter R

Blower Housing with

Fixed Guard

S Cylinder Shroud T

Fan/Flywheel

Assembly

Clean all parts thoroughly as engine is disassembled.

Only clean parts can be accurately inspected

and gauged for wear or damage. There are many

commercially available cleaners that will quickly remove

grease, oil and grime from engine parts. When such a

cleaner is used, follow manufacturer’s instructions and

safety precautions carefully.

Make sure all traces of cleaner are removed before

engine is reassembled and placed into operation. Even

small amounts of these cleaners can quickly break down

lubricating properties of engine oil.

NOTE: This disassembly sequence removes some

components in subassemblies to enable

technician to perform internal engine servicing.

Do not disconnect every EFI, electronic

governor, or electronic throttle body (ETB)

component.

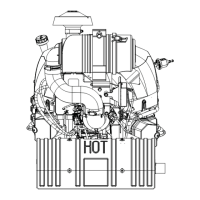

Remove High Output Charging System Terminal

Block Cover and Disconnect Stator Wires

NOTE: When high output charging system rectifi er-

regulator is supplied by Kohler, but installed by

OEM in application, you must remove terminal

block cover and disconnect stator wires before

removing engine from application.

D

C

A

B

E

F

A Torx Screw B

Terminal Block

Cover

C Rectifi er-Regulator D

OEM Supplied B+

Wiring Harness

with Charging

Fuse

E

OEM Supplied

Ground Wire

Harness

F Stator Wires

Disconnect Spark Plug Leads

NOTE: Pull on boot only, to prevent damage to spark

plug lead.

1. Disconnect leads from spark plugs.

2. Shut off fuel supply.

Drain Oil from Crankcase and Remove Oil Filter

1. Clean oil fi lter and housing area. Remove and

discard oil fi lter.

2. Remove dipstick and 1 oil drain plug.

3. Allow ample time for oil to drain from crankcase.

Remove Muffl er (if equipped)

NOTE: Unless oxygen sensor is damaged or

malfunctioning, disassembly from muffl er is

unnecessary.

1. Disconnect oxygen sensor connector from wire

harness.

2. Carefully remove sensor plug from bracket (ETB

ECV EFI only).

3. Remove exhaust system and attaching hardware

from engine. On engines equipped with port liners,

remove then now.

4. Remove oxygen sensor.

Remove Cylinder Shrouds and Blower Housing

1. Remove top mounting screw and loosen shoulder

screws on each side. Lift off cylinder shrouds.

2. Remove mounting screws and separate blower

housing from backing shroud assembly. One screw

also secures oil fi ll/dipstick tube. Fixed guard (if

equipped) may be removed with blower housing.

If engine has pulse/lift pump mounted to blower

housing, remove two mounting screws.

3. Remove lower mounting screw and pull oil fi ll tube

out of crankcase.

Remove Electric Starter Motor

1. Disconnect leads from starter.

2. Remove screws and starter.

Remove #1 Barrel and Valley Baffl es

NOTE: Unless ignition coil is being replaced,

disassembly from barrel baffl e is unnecessary.

1. Remove mounting screws from #1 barrel baffl e.

Disconnect wiring harness from coil (#1 starter side).

Let barrel baffl e hang (with coil installed).

2. If equipped, carefully remove clip securing wires to

#1 valley baffl e. Remove screws, then valley baffl e.

If necessary, remove screws securing rectifi er-

regulator (standard ignition) for access to top barrel

baffl e screw.

Loading...

Loading...