CRANKCASE VACUUM TEST

The results of a crankcase vacuum test can be very useful in

determining

the general

condition

of an engine.

A

negative pressure of specific value (or vacuum) should be present within the crankcase

when an engine is running at normal operating speed and temperature.

Crankcase vacuum reading

should be taken with the engine operating at 3200 RPM (or 3600 RPM on models operated at this speed).

Vacuum can be checked with a

"U"

tube water manometer

or

with a vacuum gauge which can he inserted

tightly in the oil fill bole. An engine in good condition will have a crankcase vacuum reading no lower

than the values stated in the accompanying chart.

TYPE BREATHER

Reed Type Breather

Closed Breather

12" H20 12

"

H20

-

NOTE:

Values shown in inches of water

(HZO) column as read on water manometer with engine operat-

-

ing at 3200 or 3600 RPM.

If vacuum is lower than the minimum values stated,

this could be attributed to several different

factors. The condition easiest to remedy should be checked first.

A.

Clogged Crankcase Breather: Can cause low vacuum or positive pressures to build up. An

improperly assembled and adjusted reed valve can also cause this. Disassemble breather,

thorouehlv clean then recheck crankcase

Dressure after serviced breather is reinstalled.

B. Worn

]jamaged Oil Seals: Oil leakage'is usually evident around worn or damaged oil

seals.

Replace oil seals and recheck vacuum.

C.

Blowby, Leaky Valves: Can be the cause of positive crankcase pressures. These condi

-

tions can he confirmed by taking compression readings on engine.

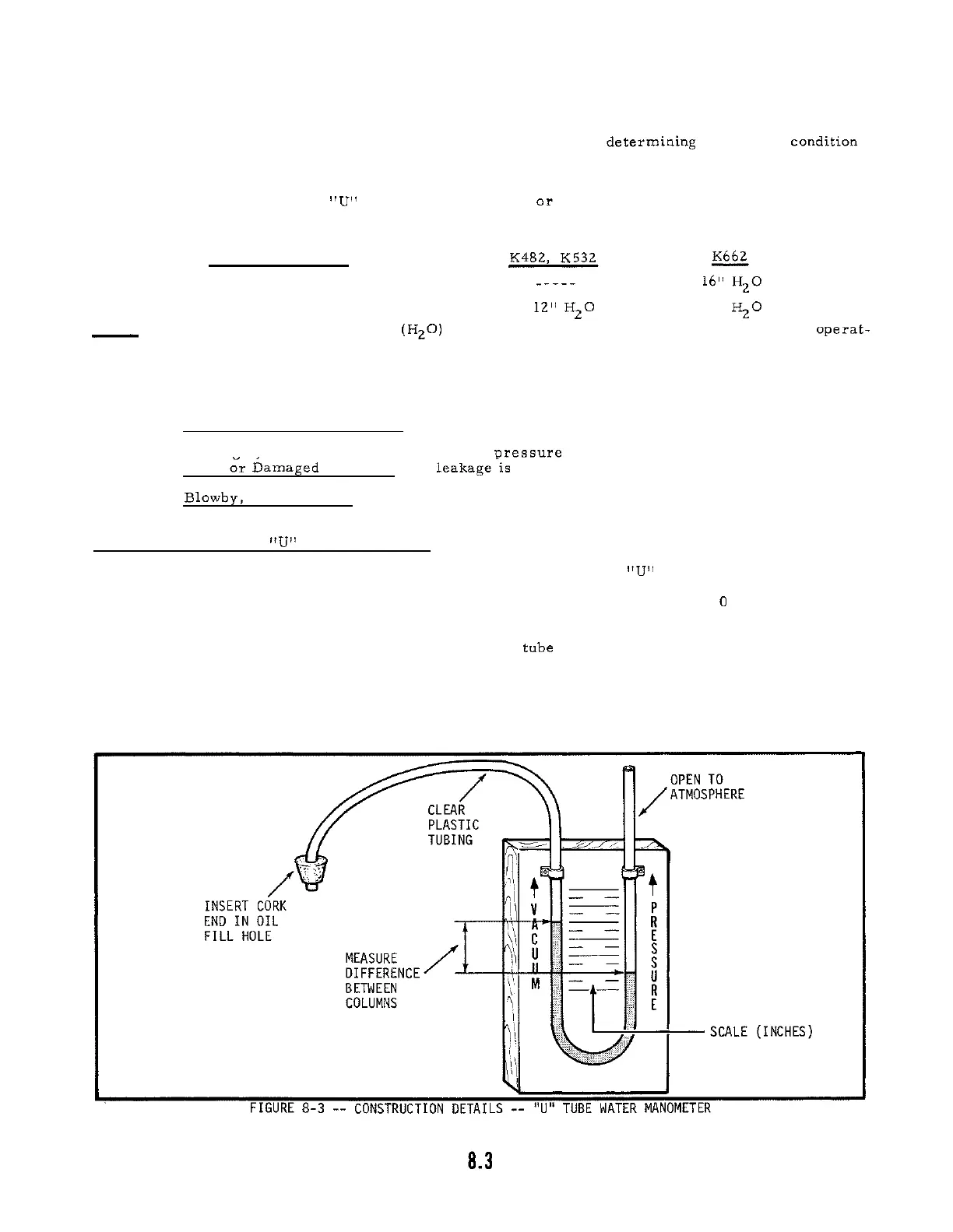

Construction Details

-

"U"

Tube Manometer: To construct water manometer, proceed as follows:

(A)

Procure length of clear plastic tubing. Bend tube to form

"U"

and mount on board as

shown in accompanying illustration. Make gradual, rather than sharp bend in tube.

(B)

Measure inside, straight section of tube and mark in increments from 0 to

24

inches.

(C)

Procure cork having outside diameter which will be a snug fit in the oil fill hole.

Drill

hole in center of cork to receive one end of tube.

(D)

Pour water (colored for easier reading) into

tube until level reaches the approximate

halfway mark on scale.

When using manometer, place cork end into oil fill hole (other end open to atmosphere) and

measure difference between columns.

If

water column is higher in tube connected to engine, vacuum

or negative pressure is indicated.

If the higher column is on the atmospheric side of manometer,

positive pressure is present.

Loading...

Loading...