CRANKCASE BREATHER SYSTEMS

The breather functions as a one

-

way valve to allow pressure to be expelled from the crankcase

and also to block or prevent air from being drawn hack into the crankcase. A proper functioning

breather system thus helps maintain a slight vacuum within the crankcase.

K482 and K532 models use a closed or positive type breather system.

A

nonserviceable breather

valve is pressed into the breather housing which is assembled to the governor.

If the valve

is

faulty,

replace breather

-

housing as a unit.

A

tube connects the breather to air inlet side of the carburetor.

The flow

of

air to the carburetor thus creates a vacuum on the tube which pulls air (and fumes) from the

crankcase to maintain vacuum.

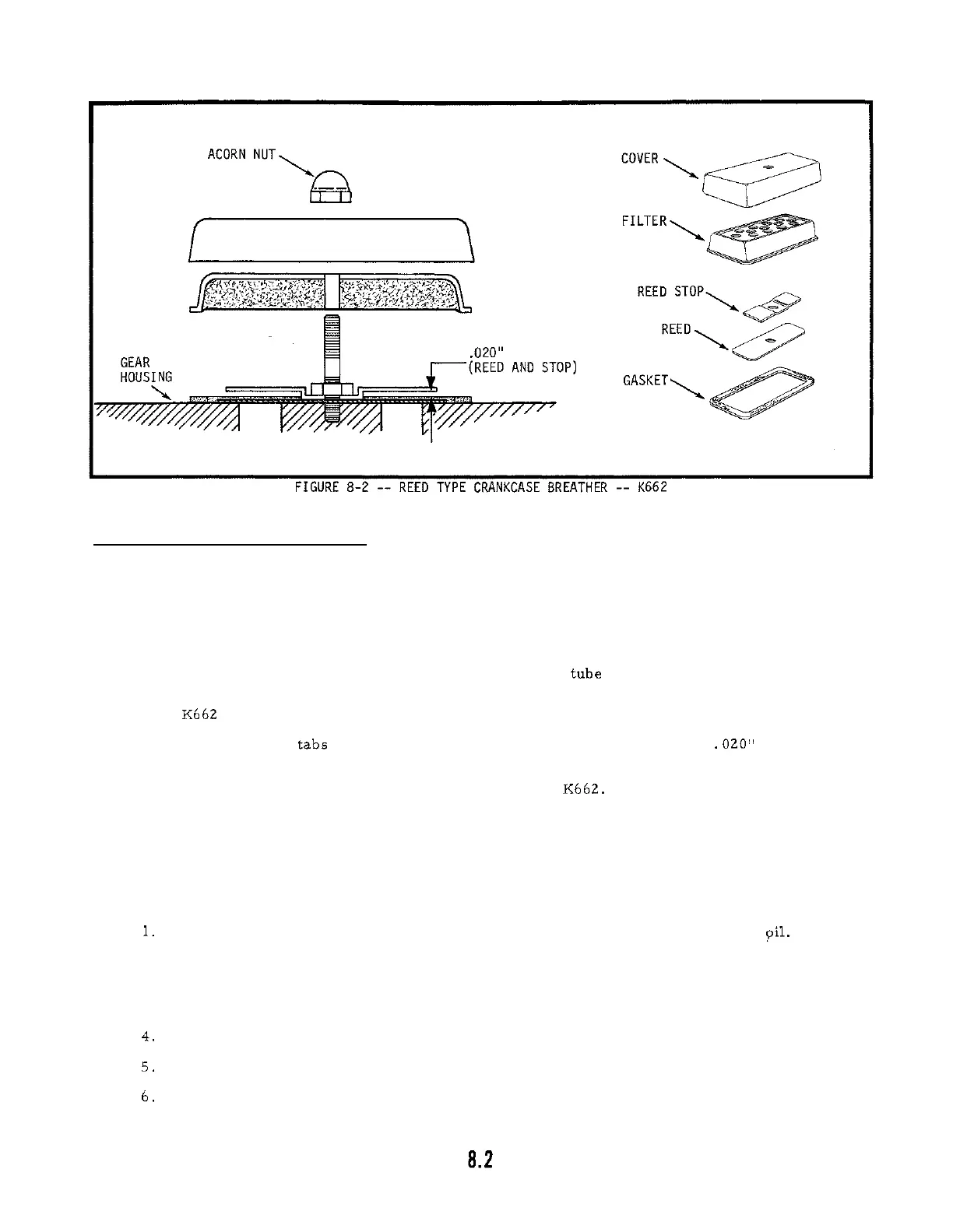

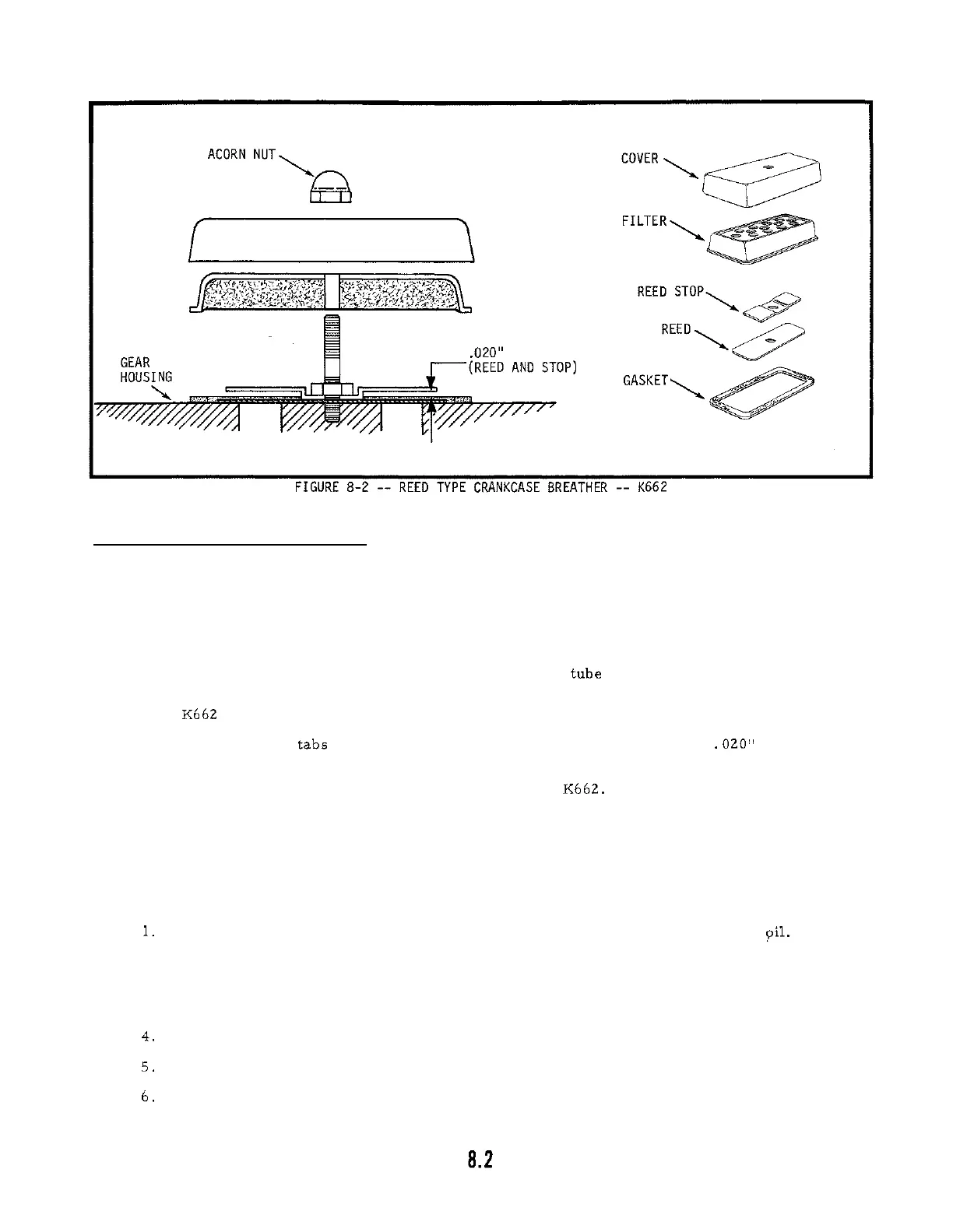

Most

K662 engines use the reed type breather arrangement as shown in Figure 8

-

2. The breather

is located at the top of the gear housing on these engines. The components must be properly installed

to function properly. The

tabs on the reed stop must be adjusted so that they are ,020" above the flat

surface of the

reed

(when the engine is not running). The reed allows air to exit from the crankcase

but blocks return of air. The filter element should be serviced occasionally so that crankcase ventila

-

tion is not blocked.

A closed system is also employed on the

K662.

The components of this system

are the same as the standard system except for a special housing. A tube connects the housing to the

air inlet side of the carburetor to maintain positive draw on breather whenever the engine is in operation.

ENGINE STORAGE INSTRUCTIONS

If engine is to be out of service for a considerable length of time, the following steps are recom

-

mended:

1.

Drain oil from crankcase while engine

is

still hot and flush with clean, light pil.

Refill

crankcase.

2.

Drain fuel tank and carburetor.

3.

Remove, clean and replace sediment bowl.

4. Clean exterior of engine.

5.

Spread a light film of oil over any exposed surfaces of engine subject to corrosion.

6.

Pour tablespoon of oil into spark plug holes, crank engine slowly by hand and replace

spark plugs.

Store in dry place.

Loading...

Loading...