CONNECTING RODS

1. Check bearing area (big end)

for

excessive wear, score marks, running and side clearance.

Replace rod hearing on K662

or

rod on K482 and K532 if worn beyond limits stated.

2.

Slightly

undersize rod bearings

(.

002

"

less than standard) are available for K662 engines when

crankpin wear is moderate.

Connecting rods

.010" undersize are availahle for the K482 and

K532.

Connecting rod hearings .010 and .020M undersize are available for K662 for use with

reground crankpin.

VALVES

-

VALVE MECHANISM

Carefully inspect valve mechanism parts. Check valves and valve seat area

or

inserts for

evidence of deep pitting, cracks or distortion. Check clearance of valve stems in guide.

Guides: If a guide is worn beyond limits, it must be replaced.

A

guide with ,010" oversize

O.D.

is

available (K662 only) for cases where guide bore in crankcase is damaged. The guide bore must be

rehored to accommodate the oversize guide.

Replacement guides must he reamed to correct size.

To remove, drive guides into valve chamber and carefully

break protruding end until guide is

completely removed.

Be

careful not to damage block when removing old guide.

Press

new

guides to

depth stated in Clearance Section. Ream to proper

I.

D.

after installation.

Valves and Valve Seats: Consult parts manual for correct valve numbers when replacing valves.

Some applications require special hard faced valves for

both intake and exhaust valves.

Exhaust

valves are always hard faced.

Intake valve seats are machined into block on most

K482 and K532

models although intake inserts may be used in certain applications.

Both intake and exhaust seat

inserts are used on the

K662.

Exhaust valves seat on special hardened inserts on both models.

If valve seat insert is

badly worn, warped, damaged or if seating surface is badly pitted, the

insert must he replaced.

The inserts are a tight press fit in the cylinder head.

A

commercial valve

seat removal tool is recommended for this job.

Since insert removal causes loss of metal in the

insert

bore area in the head, use only Kohler service replacement inserts which have knurled outer

edges to provide proper retention in the head.

Make sure service inserts are properly started and

pressed into bore to prevent cocking of the insert.

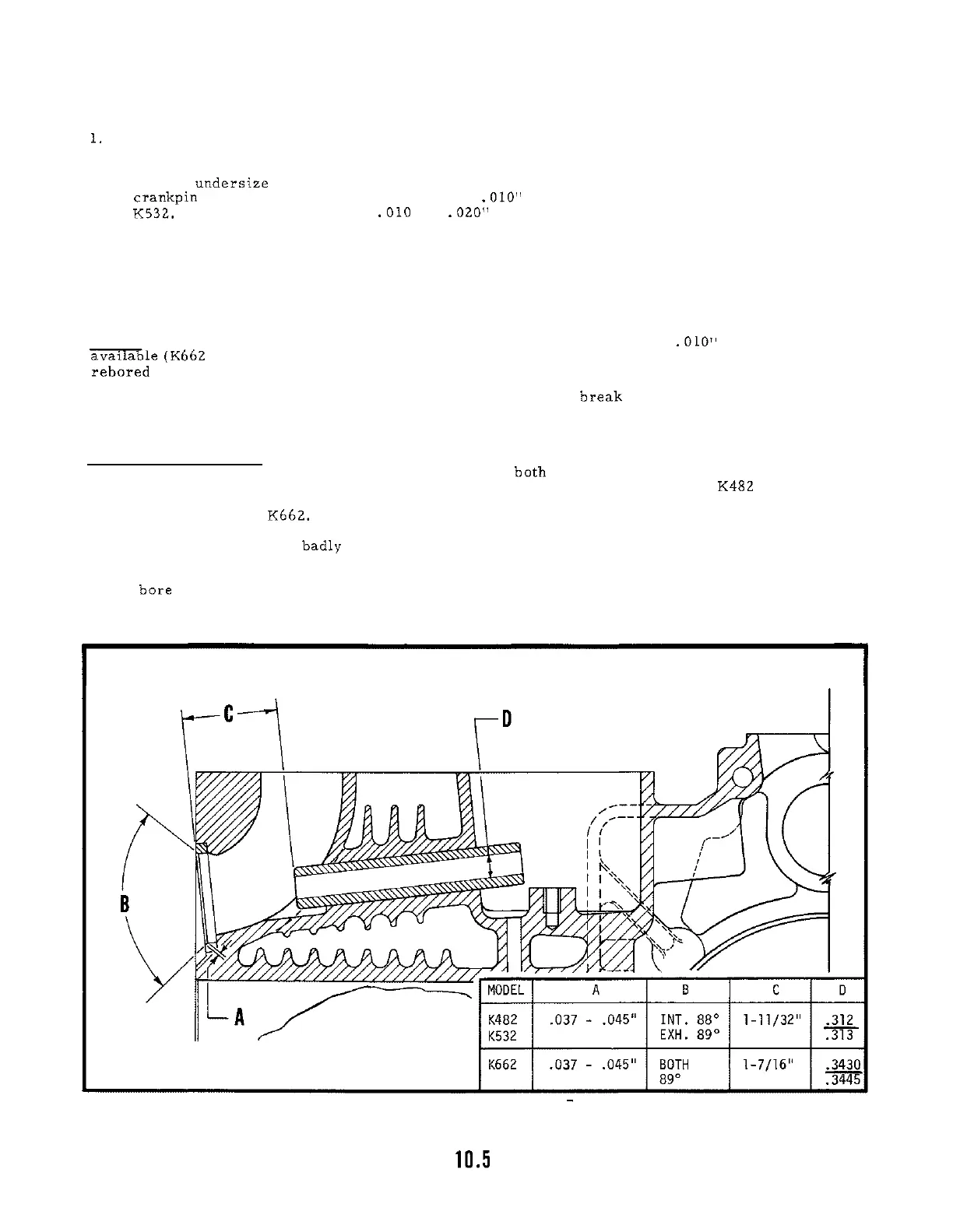

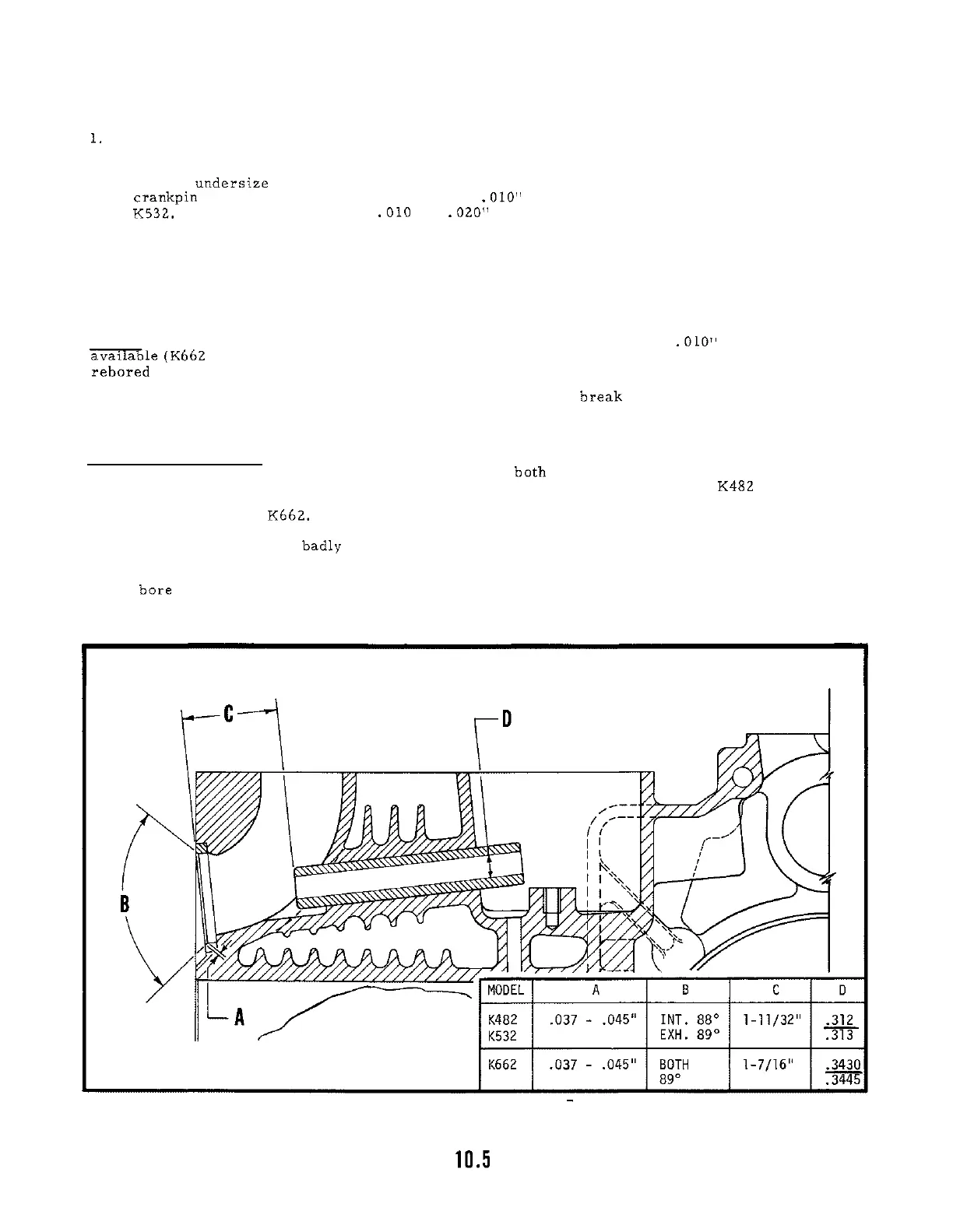

FIGURE

10

-

9

--

VALVE, VALVE PORT DIMENSIONS

-

2

CYLINDER MODELS

Loading...

Loading...