13

12

13a

13b

8

- 23 -

DISASSEMBLY/REASSEMBLY

Alwayscheckthethespringandvalvetomakesuretheyarein

agoodconditions.

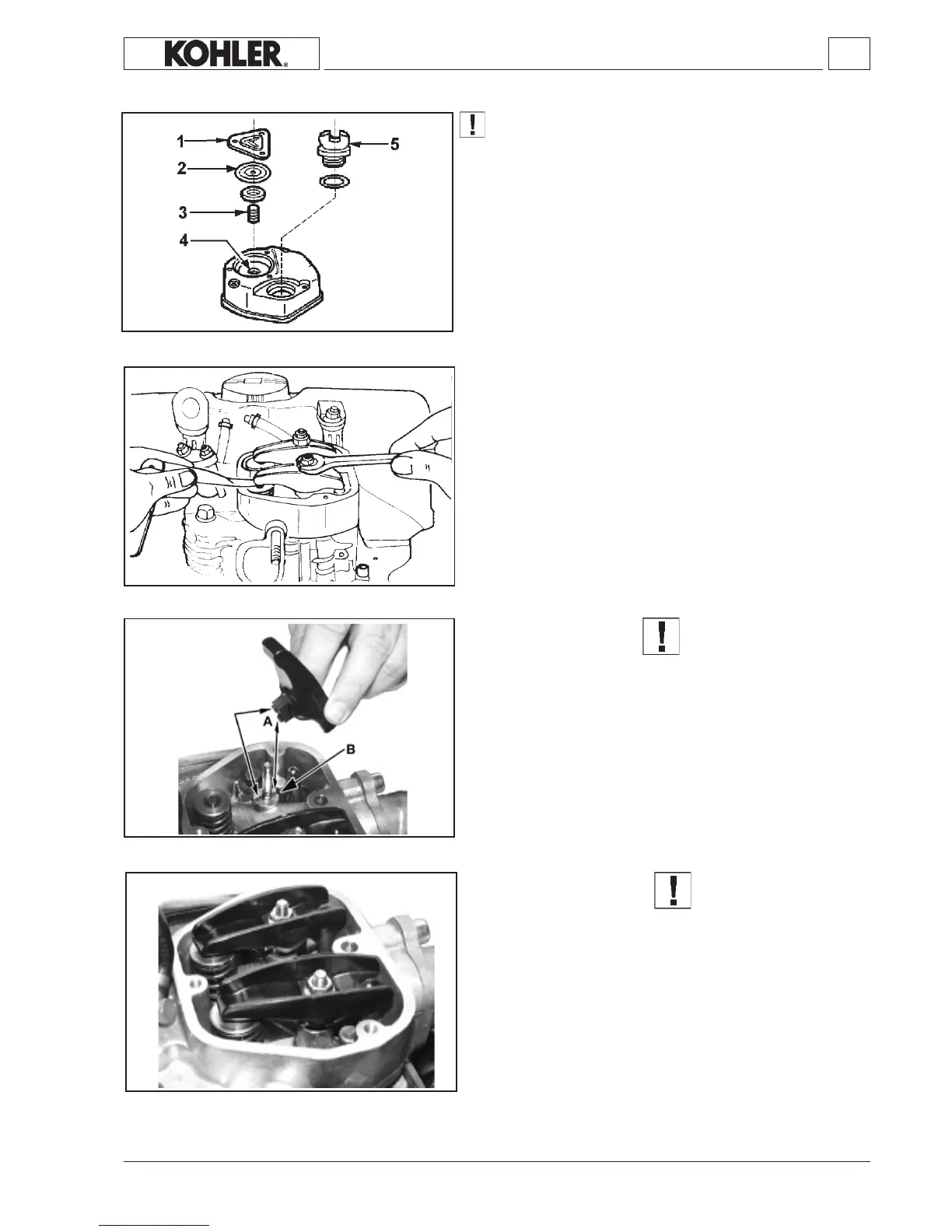

Rocker arm cover - Breather ricirculation

Crankcasevaporrecirculationoccursthroughduct4.

Iftheairlterclogs,theincreasedintakevacuumcouldsuckoilthrou-

ghduct4intothecombustionchamber,causingtheenginetooperate

atarunawayrate.Thisispreventedbyvalcuumvalve2which,when

the vacuum increases, overcomes the resistance of spring 3 and

shutstheduct4.

Makesurethatoilplug5iscorrectlyclosed.

Retcover1andtightenrockerarmcoverto10Nm.

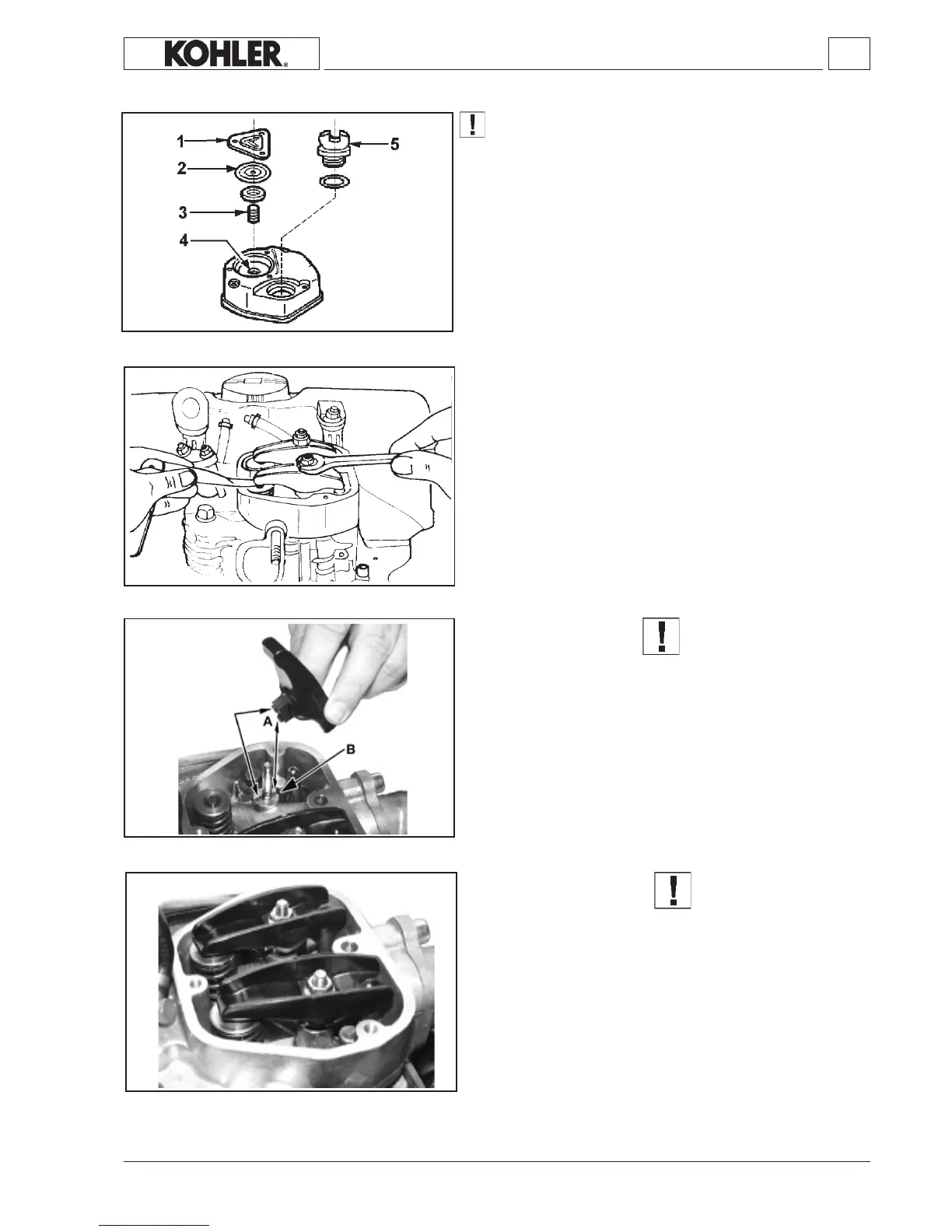

Setvalve/rockerarmclearance when theengineiscold:bringpiston

to top dead center on the compression stroke and set clearance at

0.10-0.15mmusingathicknessgauge.Tightenlocknut.

N.B.: Since an automatic decompression device is available on the

exhaustlobe,manualyrotatetheengineuntilthetappetsareat

lowestpoint.

When replacing the rocket arms, position the piston at the bottom

dead centre and tighten the xing screw gradually to adjust the

hydraulictappets.

Whiletightening,makesurethatA tscorrectlyintoB(g.13a).

Theadjustingscrewpinshouldbetightenedto20Nm.

Do not start the engine for approximately 4 hours to allow the

hydraulic tappets to settle completely.

Oncethetappetshavesettled,tightentheboltto10Nm.

KD 225_315_350_400_440 Workshop Manual_cod. ED0053029330_1° ed_ rev.00

Valve/rocker arm clearance ( KD 225-315-350 )

The engines KD 400 and 440 have hydraulic tappets, therefore

no adjustment is required.

Loading...

Loading...