- 38 -

KD 702_1003_1404 Workshop Manual_cod. ED0053029340_1° ed_ rev. 00

6

4

1

2

3

Disassembly / Reassembly

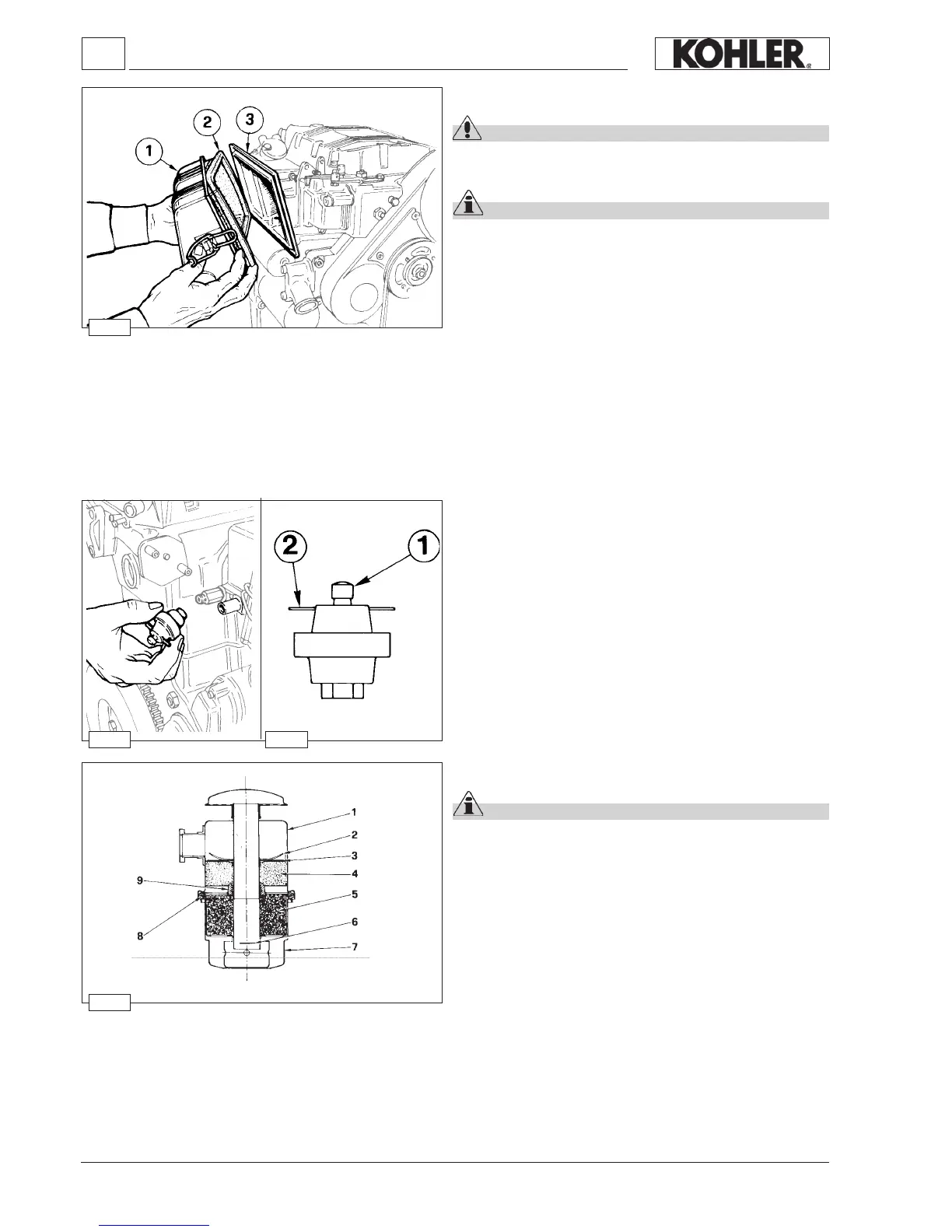

Dry type air lter

Danger - Attention

Never clean the ltering element with highly ammable sol-

vents Danger of explosion!

Important

Blow compressed air crossways over the external part and

inside the cartridge at a pressure no greater than 5 atm

or if necessary knock the front of the cartridge repeatedly

against a at surface.

Components: 1 Cover

2 Filter element

3 Support

Air lter specications:

Filtration level = 13÷14 µm.

Filtration area = 4470 cm² for 702, 1003

Filtration area = 7150 cm² for 1404

See page 32 for periodic maintenance details.

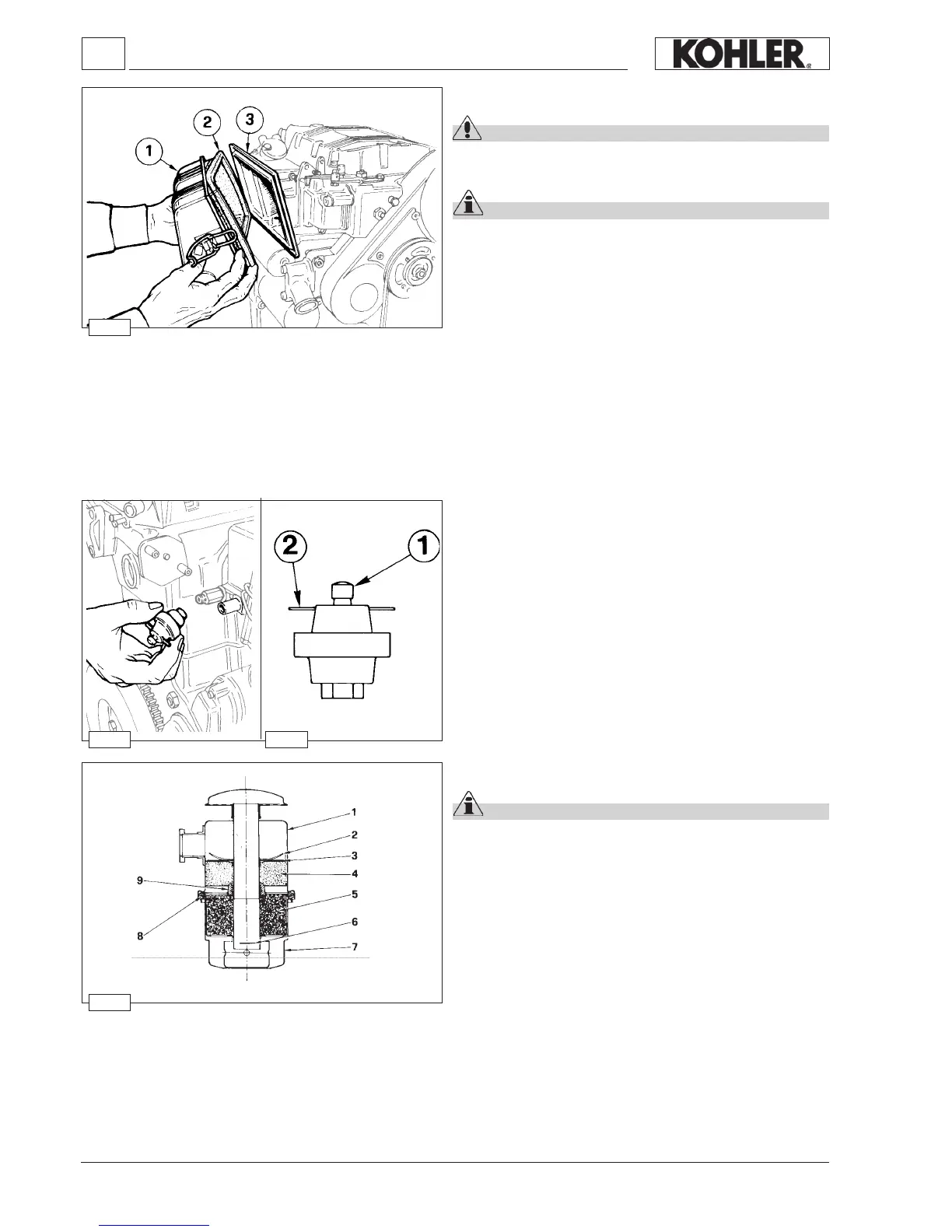

Air restriction switch

Components:

1 Reset buttione

2 .25" Tab connection

Note:

The indicator is calibrated at 600÷650 mm of water co-

lumn for KDW 702, 1003, 1404.

Oil bath air cleaner (on request)

Important

Check the sealing rings regularly.

Replace the sealing rings if hardening or damage is noted

1 Upper Housing 6 Oil level reference mark

2 Diaphragm Seat 7 Reservoir bowl

3 Diaphragm 8 Outer seal ring

4 Polyurethane upper element 9 Inner seal ring

5 Metal wool lower eleme

Note: Carefully clean the reservoir bowl and both elements with

clean diesel fuel. Blow the lower element dry with com-

pressed air. Dry the upper element by squeezing out ex-

cess diesel fuel, then drying with suitable cloths.

Fill the reservoir with clean engine oil to the reference

mark.

See page 32 for periodic maintenance and replacement

details.

Loading...

Loading...