5 Function description

5.1 Functional principle

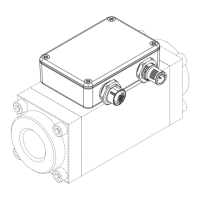

Fig.4: Connecting several processing units

1 Flowmeter with processing unit 5 Display device (HMI)

2 Flowmeter with processing unit 6 Power supply display device

3 Flowmeter with processing unit C1 Power supply processing unit

4 Terminating resistor C2 Connection Modbus RS-485

Up to 32 processing units can be connected (32 sensor evaluations electrically in parallel).

5.1.3 Volume measurement

The volume is calculated cyclically by counting of the pulses divided by the K-factor (in pulses/liter).

The flow rate is always defined by volume/time unit.

o The totalled overall flow ("Total_Volume_1" parameter) can only be reset in the works.

o The totalled overall flow ("Total_Volume_2" parameter) can only be reset by the user.

5.1.4 Linearization

The K-factor of a flowmeter shows slightly different values at different flow rates. These are docu-

mented in the enclosed calibration certificate. In order to improve the measuring precision these differ-

ent values can be taken into consideration by means of a "Linearization". To this purpose the K-factors

are stored for a maximum of eight interpolation values. The K-factor relevant for the currently meas-

ured flow rate is then determined with linear interpolation between the two nearest interpolation values.

5.1.5 Density determination

The flowmeters are equipped with a temperature sensor.

The density of the medium is determined by means of the measured temperature. To this purpose the

processing unit provides six different modes:

o Density calculation for fuel oils LDO/MDO or HFO (Mode 4, 5, 6)

Here only the density at 15°C has to be entered.

o Density calculation for other media (Mode 0, 1, 2)

5.1.6 Mass measurement

The mass is calculated from volume times density.

5.1.7 Differential measurement and synchronization

Two flowmeters are used for differential measurement - one flowmeter in the feed line and one flow-

meter in the return line. The "Hold" function is available for the synchronization. This function allows the

HMI to set the output registers of the processing units briefly to "Hold" and thus to fetch the measured

values for the differential generation – at the current moment – while in the background the processing

units continue to measure the pulses received from the flowmeters and carry out all calculations.

5.1.8 Averaging

A strongly fluctuating flow rate causes the display to jump, making an interpretation by the user difficult.

The averaging function reduces this effect by generating an averaging across several measured

values.

Operating instructions

OIE 26en-GB Edition 2021-08

7

Loading...

Loading...