12 Servicing

12.5 Cleaning the strainer

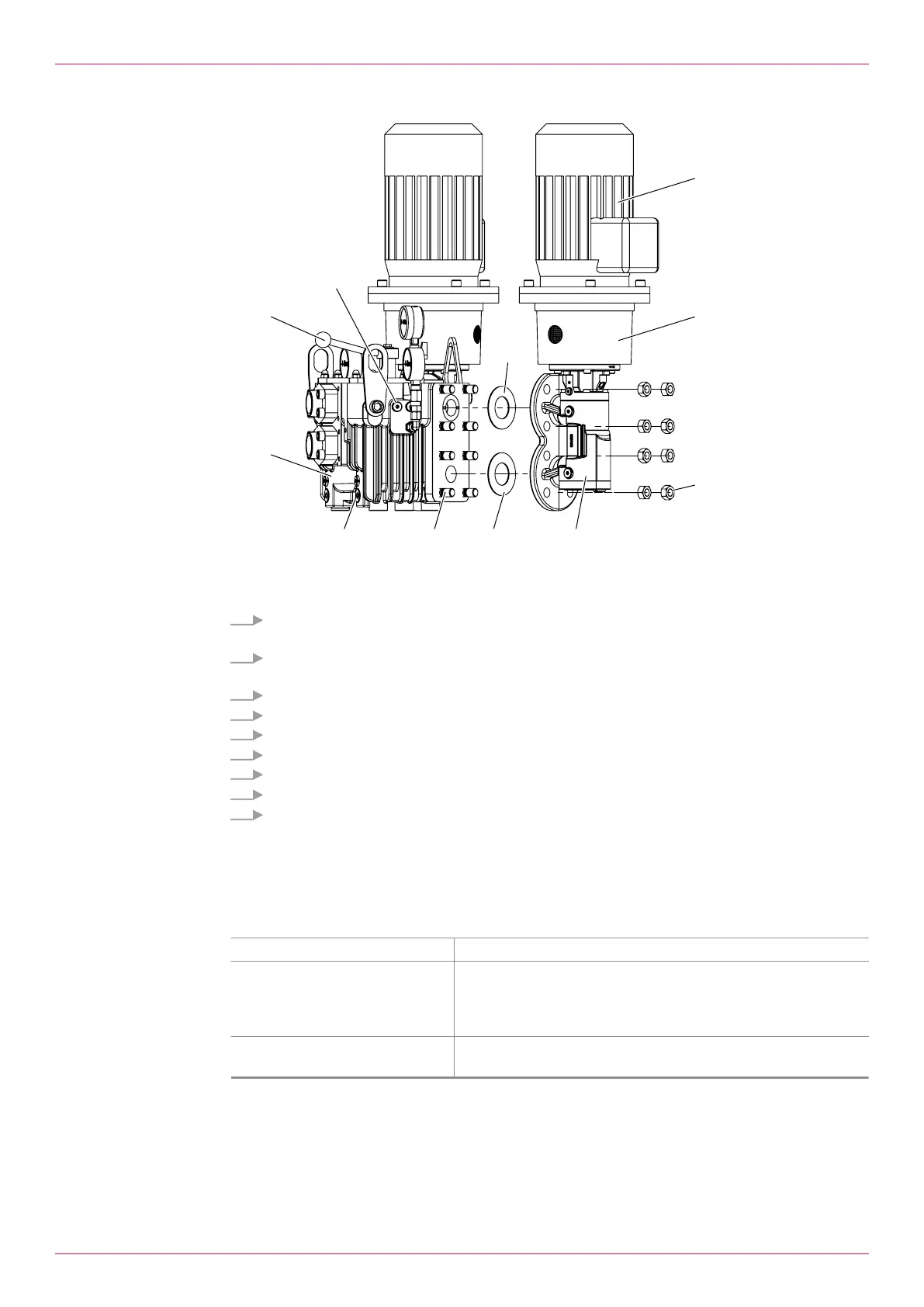

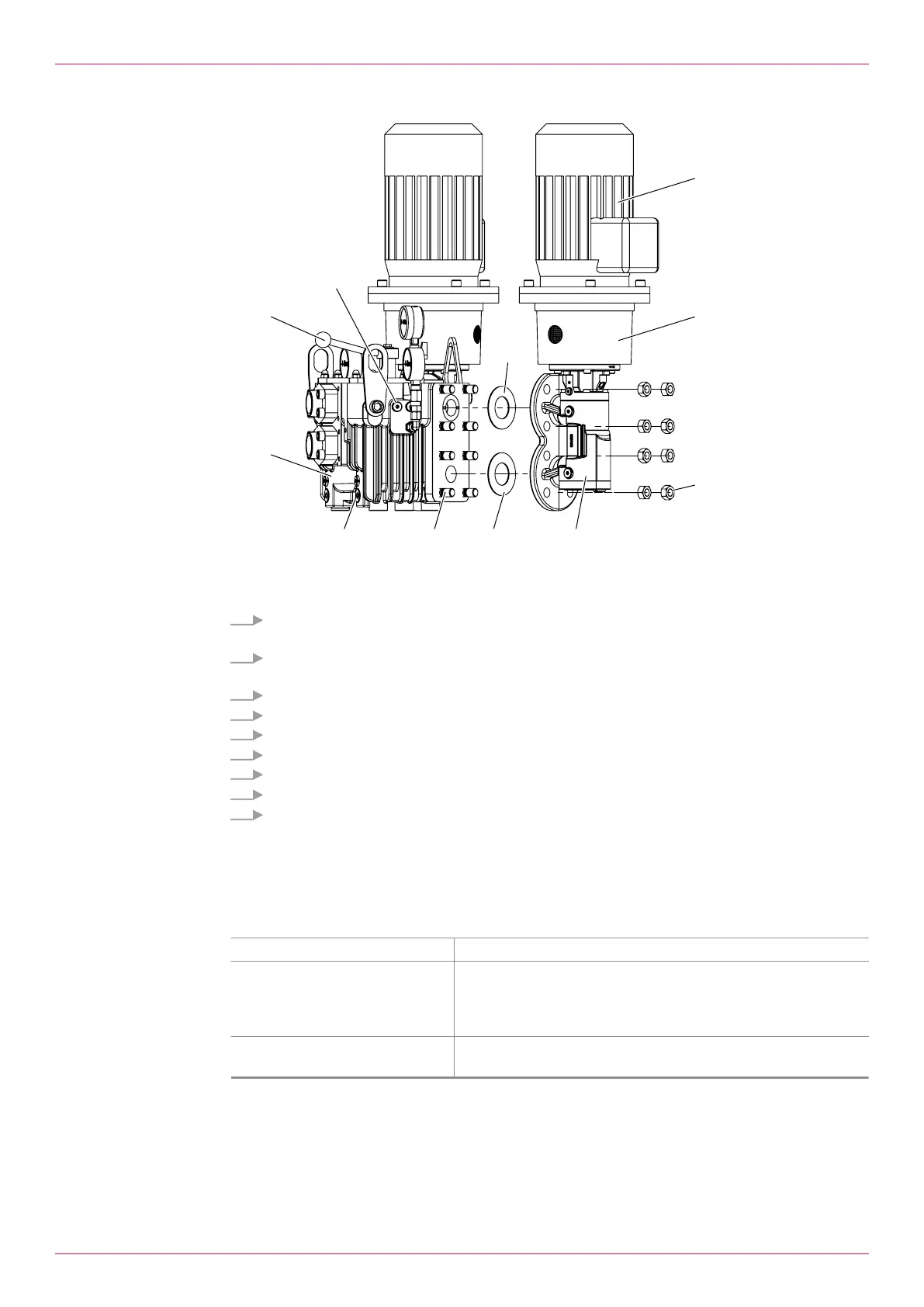

Fig.24: Replacing the pump

1. Switch over the lever of the reversing valve11 in order to shut off the respective side Ä During

operation,Page34.

2. Open the screw plug of the vent hole1 by a max. of two rotations in order to reduce the internal

pressure in the housing.

3. Remove the screw plug9 in order to drain the liquid in the strainer chamber.

4. Remove the hexagon nuts5 at the pump flange.

5. Dismantle the pump6, remove the flat gaskets2 and7.

6. Clean the sealing surfaces, place on new flat gaskets.

7. Place the new pump on the stud screws8, tighten the hexagon nuts5.

8. Tighten the screw plug9 at the station block again.

9. Fill and vent the strainer chamber Ä Commissioning,Page30.

12.5 Cleaning the strainer

The frequency of cleaning the filter depends on the degree of soiling of the pumped liquid. In case of

strongly soiled strainers cavitation and strong noise generation arise. The suction-side pressure gauge

is used to indicate the degree of soiling.

Personnel qualification: o Trained personnel

Personal protective equipment: o Work clothing

o Face protection

o Protective gloves

o Safety boots

Aids: o Collection tank

o Solvent

Operating instructions

OID 02en-GB Edition 2019-11

41

Loading...

Loading...