8.

Operation

For a strong joint, the pocket screw should exit at the center of

the workpiece thickness. This is accomplish this by adjusting the

fence position.

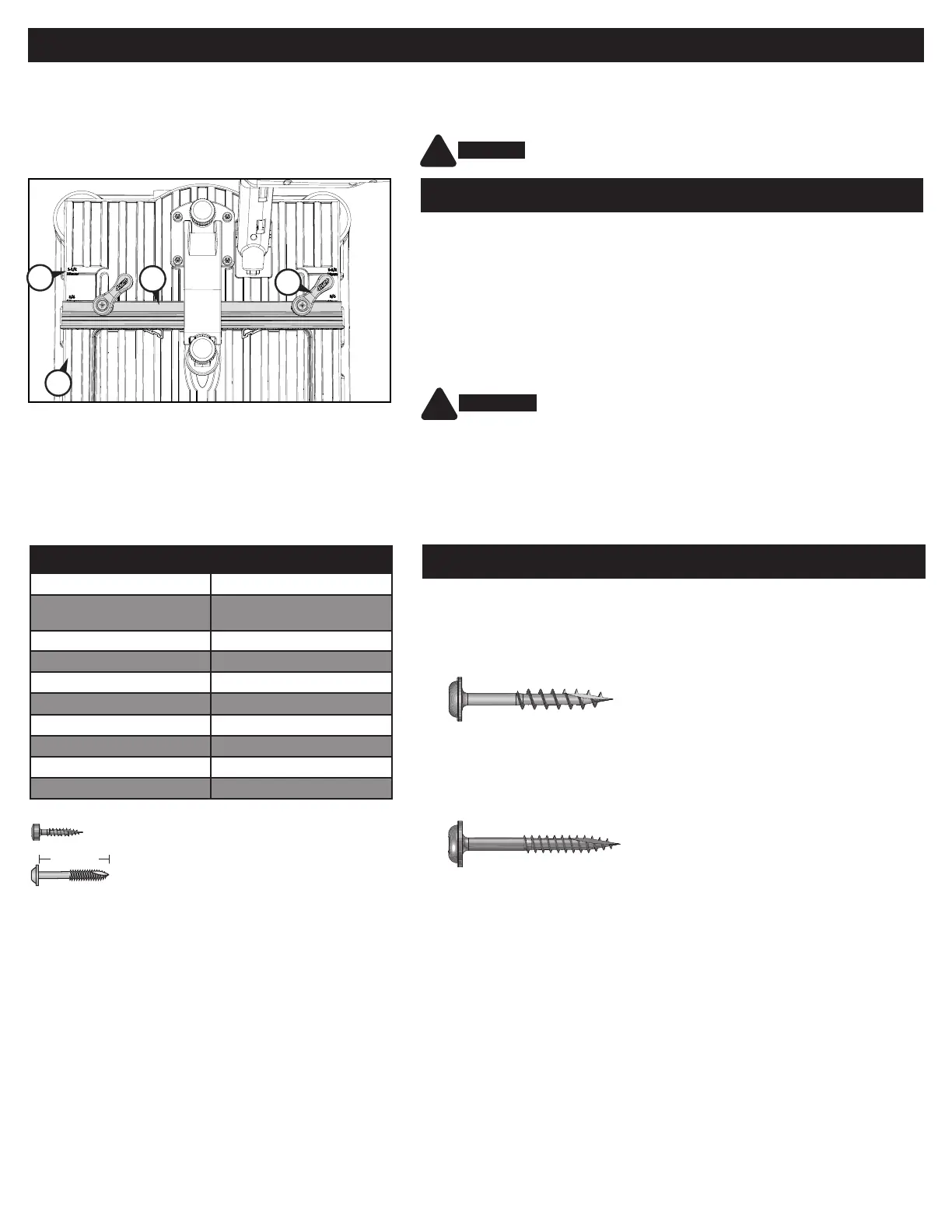

Unlock the fence (16) by rotating the fence-lock handles (15)

counterclockwise. Align the rear edge of the fence with the workpiece

thickness marks (21) cast into the machine top (12) that correspond

to your workpiece thickness. Rotate the handles clockwise to lock the

fence in place.

(1) Position the Fence for Workpiece Thickness

To create strong joints, you’ll adjust machine settings to match the

thickness of the workpiece and the length of the screw. The Foreman

makes this easy, in just four simple steps:

Screw Length Selection Guide

Material Thickness Screw Length

1

⁄2" [13 mm]*

1" [25 mm]†

3

⁄4" [19 mm]††

5

⁄8" [16 mm] 1" [25 mm]

3

⁄4" [19 mm] 1

1

⁄4" [32 mm]

7

⁄8" [22 mm] 1

1

⁄2" [38 mm]

1" [25 mm] 1

1

⁄2" [38 mm]

1

1

⁄8" [29 mm] 1

1

⁄2" [38 mm]

1

1

⁄4" [32 mm] 2" [51 mm]

1

3

⁄8" [35 mm] 2" [51 mm]

1

1

⁄2" [38 mm] 2

1

⁄2" [64 mm]

Kreg offers a complete line of pocket screws for every workpiece

thickness and type. Use this chart to select the correct screw length.

All Kreg pocket screws are available at your Kreg dealer or online at

www.kregtool.com.

12

21

16

15

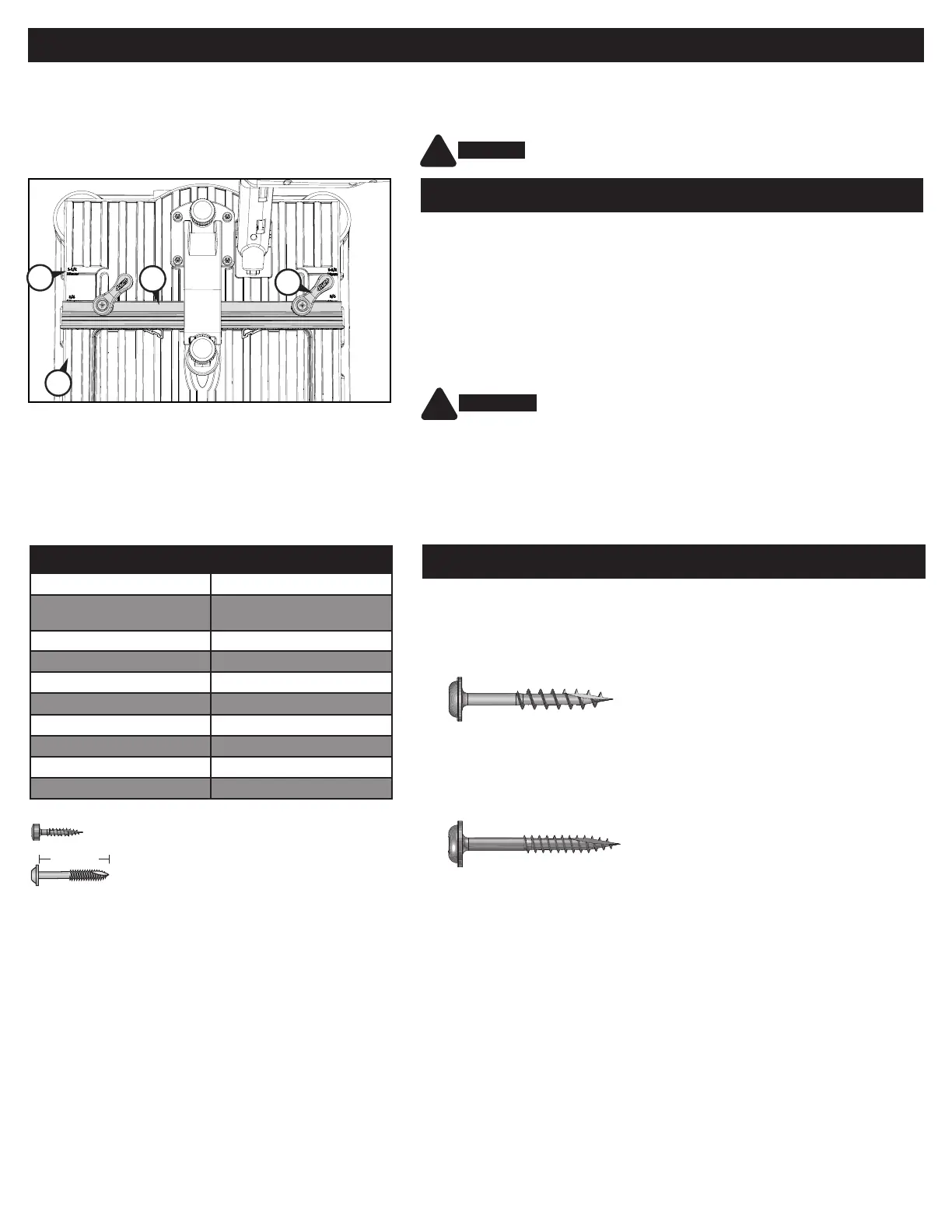

Fine Thread

Because the smaller diameter and thread pitch of our #7 ne-thread screws reduce

the chance of splitting the material, we recommend them for hardwoods.

Coarse Thread

Due to the large diameter and thread pitch, our #8 coarse-thread screws offer a

strong hold in softwoods and composite materials such as plywood, particleboard,

and MDF.

Do not reach inside the machine base from the bottom

when the machine is connected to power.

!

WARNING

When drilling pocket holes in ½" [13mm]-thick

material using the optional Micro Pocket™ drill guide and drill

bit, the rear edge of the fence must be positioned ⅛" [3mm]

behind the lines marked ½" that are cast into the machine top.

This produces a pocket hole deep enough to fully seat a ¾"

[19mm]-long panhead pocket screw and allows plugging with a

Micro plug.

!

ATTENTION

(2) Choose a Screw

Note: Screw length is measured from

bottom of the head to the tip of the screw.

1

1

⁄4" [32mm]

*Panhead pocket screw recommended. †For standard Drill Guide

††For optional Micro Drill Guide only

Loading...

Loading...