6 Installation at Site

36 of 60

6 Installation at Site

6.1 General information/Safety regulations

The consultant, construction company or operator are responsible for positioning

and installing the valves. Planning errors and installation errors may impair the

reliable function of the valves and pose a substantial safety hazard.

6.2 Installation

CAUTION

Welding in close proximity to soft-seated valves

Damage to the seat/disc interface!

▷ Ensure that the valve is not heated beyond the temperature limits specified in

the type series booklet.

Only use fasteners (e.g. to DINEN1515-4) and flange gaskets (e.g. to DINEN1514)

made of materials approved for the respective valve size. Always use all flange bolt

holes provided when connecting the valve to the pipe. Refer to the type series

booklet for details on flange connections.

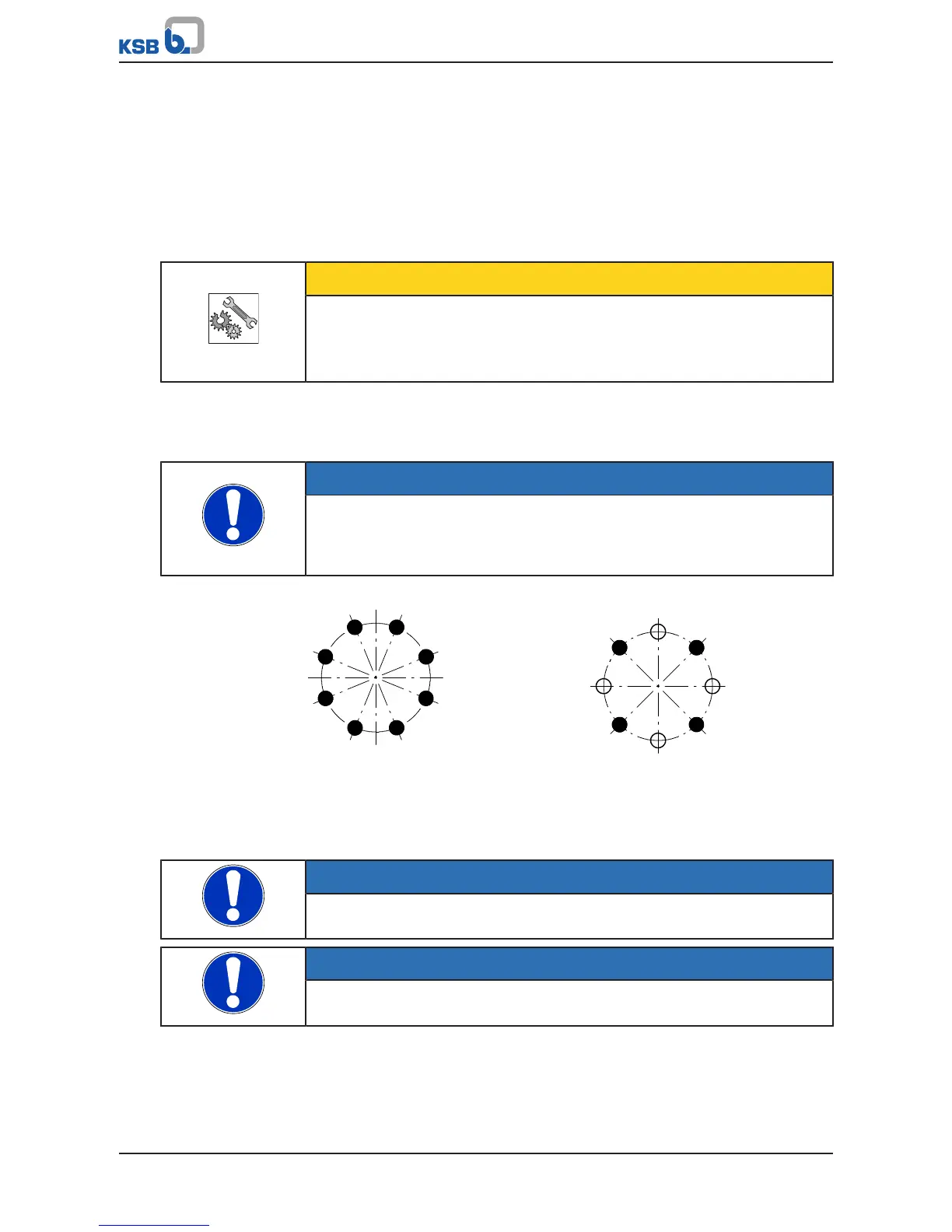

NOTE

Exception: DN 65 PN 16

When using steel flanges to DINEN1092-1 in conjunction with cast iron valves with

flanges machined to DINEN1092-2, ensure that for nominal size DN65 classed

PN16 the mating flanges are fitted offset by 22.5°.

Table29: Valve bolting DN65 PN16

DN65 PN10/16 (steel/steel):

DINEN1092-1 with DINEN1092-1:

bolts through 8holes

DN65 PN10/16 (steel/cast iron):

DINEN1092-1 with DINEN1092-2: bolt

hole circle to DINEN1092-1 rotated by

22.5°, bolts through 4holes, 4holes

free

NOTE

For the valves to reach the documented Kv values, the flow direction must

correspond to the flow direction arrow.

NOTE

An alternating direction of flow is permitted unless restrictions apply to specific

products.

6.3 Insulation

For handling hot fluids, the valve should be insulated in accordance with the German

energy-saving regulations.

Loading...

Loading...