7.2.3.1.4 Changing the oil

WARNING

Lubricants posing a health hazard and/or hot lubricants

Hazard to persons and the environment!

▷ When draining the lubricant take appropriate measures to protect persons and

the environment.

▷ Wear safety clothing and a protective mask, if required.

▷ Collect and dispose of any lubricants.

▷ Observe all legal regulations on the disposal of fluids posing a health hazard.

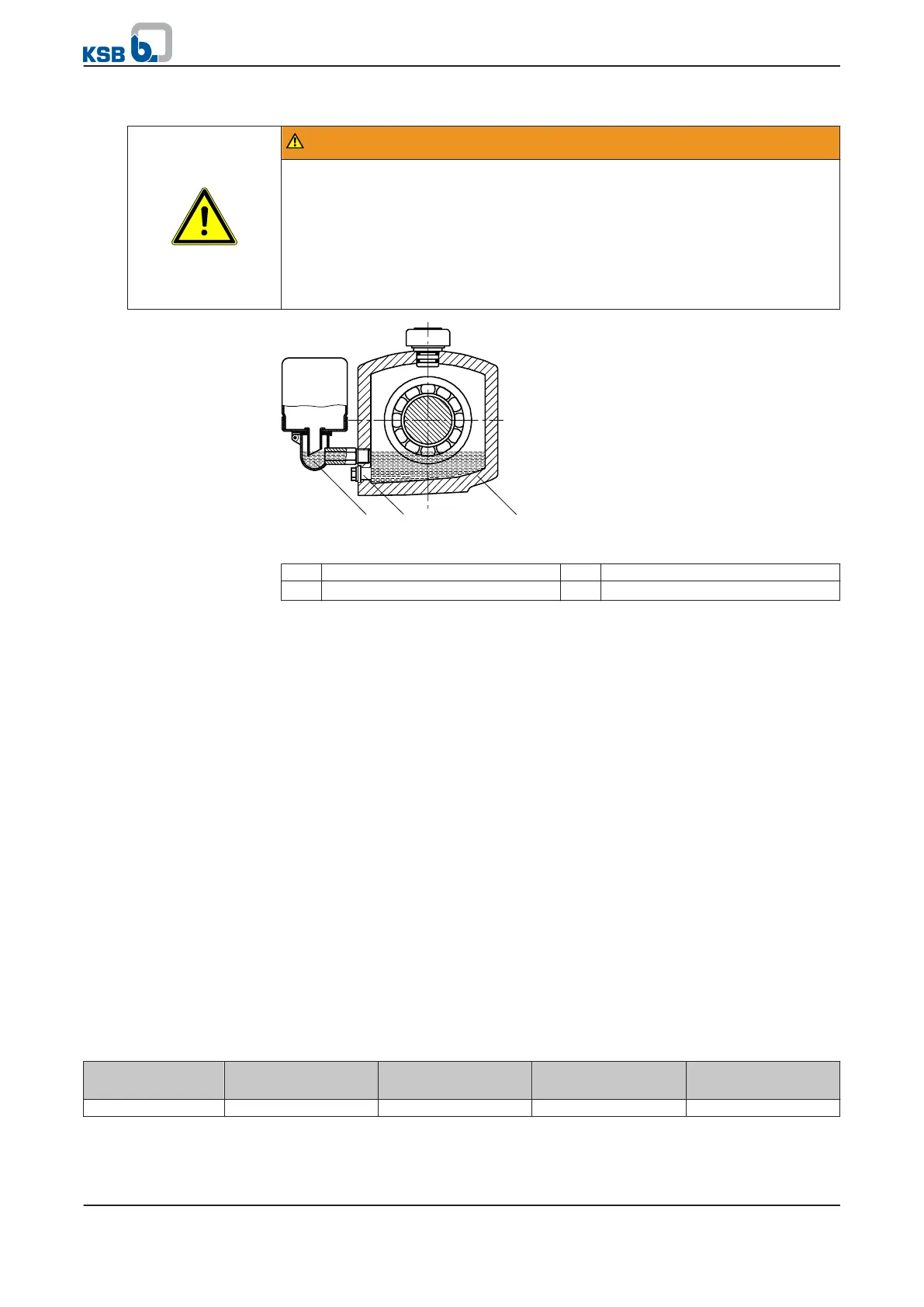

Fig. 17: Bearing bracket with constant level oiler

1

Constant level oiler 2 Screw plug

3 Bearing bracket

✓ A suitable container for the used oil is on hand.

1. Place the container underneath the screw plug.

2. Undo the screw plug (2) at the bearing bracket (3) and drain the oil.

3. Once the bearing bracket (3) has been drained, re-insert and re-tighten the

screw plug (2).

4. Re-fill with oil. (⇨ Section 6.1.2 Page 33)

7.2.3.2

Grease lubrication

The bearings are supplied packed with high-quality lithium-soap grease.

7.2.3.2.1 Intervals

▪ Under normal operating conditions the grease-lubricated bearings will run for

25,000 operating hours.

▪ Under unfavourable operating conditions (e.g. high room temperature, high

atmospheric humidity, dust-laden air, aggressive industrial atmosphere, etc.)

check the bearings earlier and clean and re-lubricate them, if required.

▪ Replace the rolling element bearings after 25,000 operating hours or 2 years of

continuous operation.

7.2.3.2.2 Grease quality

Table 21: Grease quality to DIN 51825

Soap basis NLGI grade Worked penetration

at 25 °C in mm/10

Drop point Temperature range

Lithium 2 to 3 220-295 ≥ 175 °C -30 °C to 120 °C

7 Servicing/Maintenance

MegaCPK

47 of 74

Loading...

Loading...