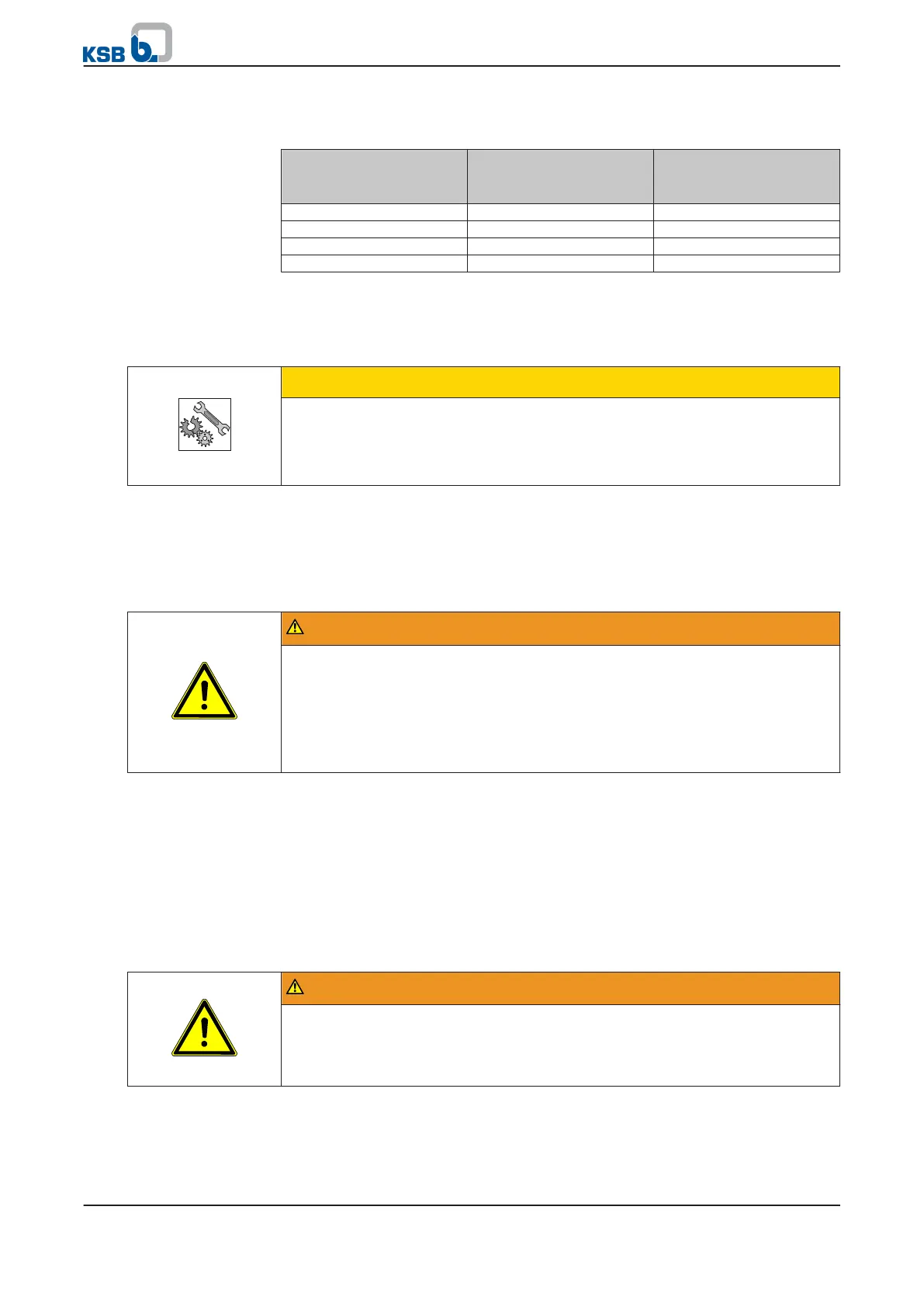

7.2.3.2.3 Grease quantities

Table 22: Grease quantities for new grease fill

Bearings Bearing + cover,

pump-end

[g]

Bearing + cover,

drive-end

[g]

CS40 15 40

CS50 30 100

CS60 50 150

CS80 50 80

Economy bearings are greased for life; the grease fill cannot be renewed. If

necessary, replace the complete bearing.

7.2.3.2.4 Changing the grease

CAUTION

Mixing greases of differing soap bases

Changed lubricating qualities!

▷ Thoroughly clean the bearings.

▷ Adjust the re-lubrication intervals to the grease used.

✓ The pump has been dismantled for changing the grease. (⇨ Section 7.4 Page 48)

1. Only half-fill the bearing cavities with grease.

2. Fill the cavities in the bearing cover until they are about 1/3 full.

7.3 Drainage/cleaning

WARNING

Fluids, consumables and supplies which are hot and/or pose a health hazard

Hazard to persons and the environment!

▷ Collect and properly dispose of flushing fluid and any residues of the fluid

handled.

▷ Wear safety clothing and a protective mask, if required.

▷ Observe all legal regulations on the disposal of fluids posing a health hazard.

If the pump set has handled fluids whose residues could lead to corrosion damage in

the presence of atmospheric humidity or could ignite upon contact with oxygen, the

pump set must be neutralised, and anhydrous inert gas must be blown through the

pump to ensure drying.

Use connection 6B to drain the fluid handled (see auxiliary connections).

7.4 Dismantling the pump set

7.4.1 General information/Safety regulations

WARNING

Unqualified personnel performing work on the pump (set)

Risk of injury!

▷ Always have repair and maintenance work performed by specially trained,

qualified personnel.

Medium-duty

Economy

7 Servicing/Maintenance

48 of 74

MegaCPK

Loading...

Loading...