3 WORK 11

Info

The heim joint for the shock absorber at the swing arm is Teflon

coated. It must not be lubricated with grease or with other lubricants.

Lubricants dissolve the Teflon coating, thereby drastically reducing the

service life.

B02158-11

(All 250/300 models)

–

Push splash protector

to the side and position the shock absorber. Mount

and tighten screw

.

Guideline

Screw, top shock

absorber

M12 80 Nm

(59 lbf ft)

Loctite

®

2701™

–

Mount and tighten screw

.

Guideline

Screw, bottom shock

absorber

M12 80 Nm

(59 lbf ft)

Loctite

®

2701™

Info

The heim joint for the shock absorber at the swing arm is Teflon

coated. It must not be lubricated with grease or with other lubricants.

Lubricants dissolve the Teflon coating, thereby drastically reducing the

service life.

Finishing work

– Remove the motorcycle from the lift stand. ( p. 8)

3.8 Installing the front wheel

Warning

Danger of accidents Reduced braking efficiency due to oil or grease on the brake discs.

– Always keep the brake discs free of oil and grease, and clean them with brake cleaner when necessary.

M00119-11

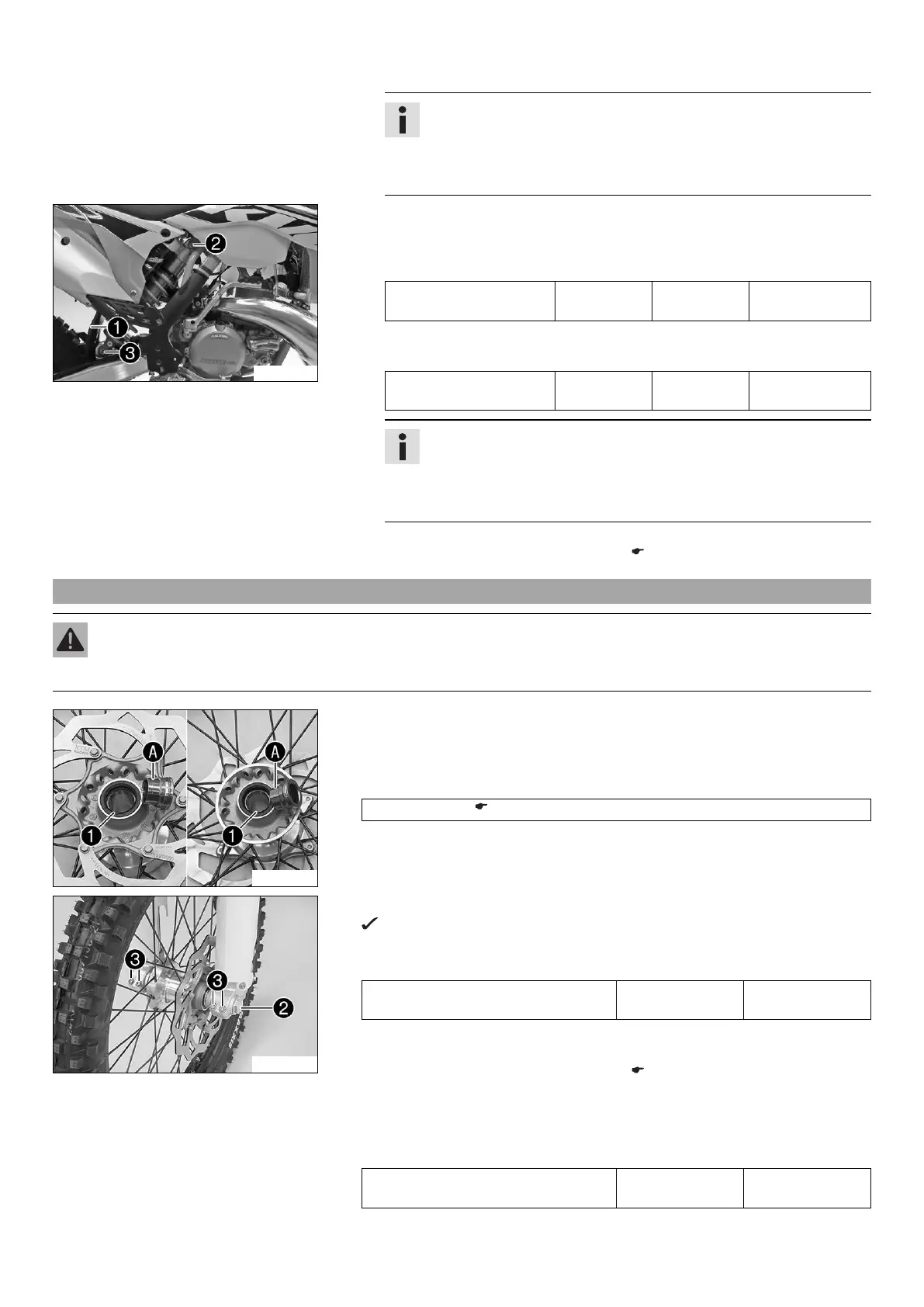

– Check the wheel bearing for damage and wear.

» If the wheel bearing is damaged or worn:

– Change the wheel bearing.

–

Clean and grease shaft seal rings

and bearing surface

of the spacers.

Long-life grease ( p. 20)

– Insert the spacers.

M00117-11

– Lift the front wheel into the fork, position it, and insert the wheel spindle.

The brake linings are correctly positioned.

–

Mount and tighten screw

.

Guideline

Screw, front wheel spindle M24x1.5 45 Nm

(33.2 lbf ft)

– Operate the hand brake lever several times until the brake linings are lying correctly

against the brake disc.

– Remove the motorcycle from the lift stand. ( p. 8)

– Pull the front wheel brake and push down hard on the fork several times to align

the fork legs.

–

Tighten screws

.

Guideline

Screw, fork stub M8 15 Nm

(11.1 lbf ft)

Loading...

Loading...