S.1

ENGINE

BODY

68mmSTROKESERlES WSM,O1165

Factory

spec.

Valve clearance

AI

16F016

0.145 to 0.1 85

mm

0.0057

to

0.0073 in.

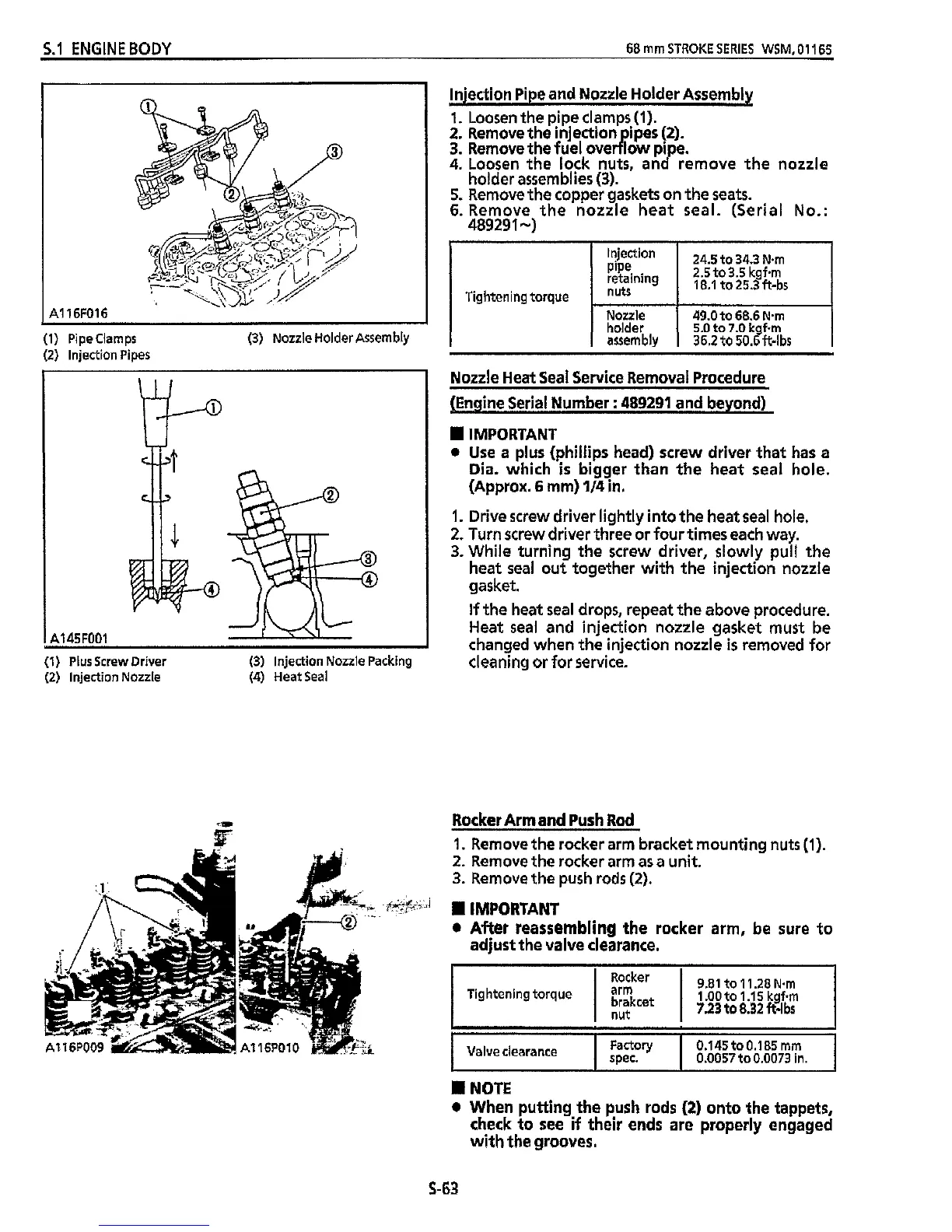

(1) Pipeclamps (3) Nozzle Holder Assembly

(2) Injection Pipes

I

A145F001

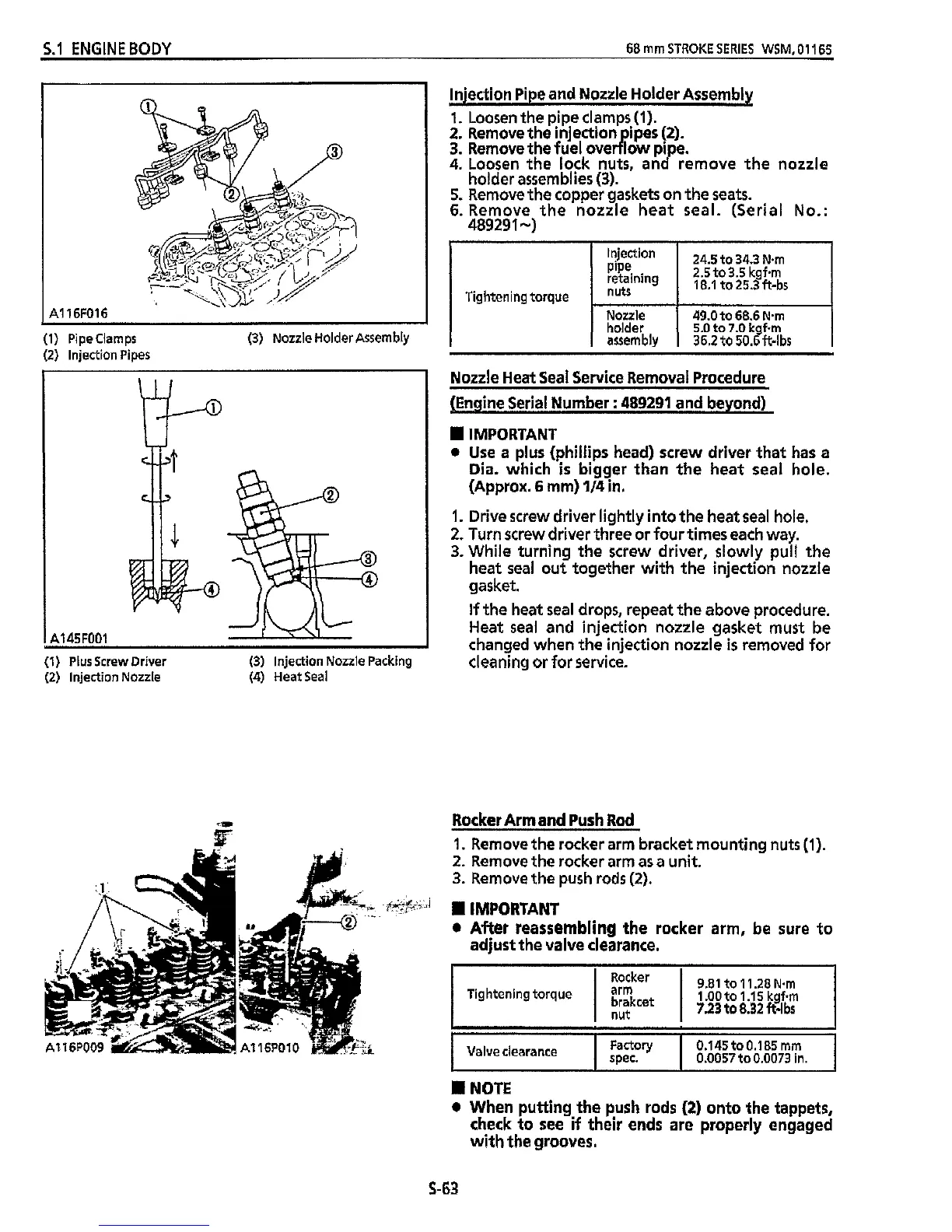

(1)

Plusscrew Driver (3) injection Nozzle Packing

(2) Injection Nozzle

(4)

HeatSeal

Injection Pipe and Nozzle Holder Assembly

1.

Loosen the pipe clamps

(1).

2.

Remove the injection ipes

(2).

4.

Loosen

the

lock nuts, and remove the nozzle

holder assemblies

(3).

5.

Remove the copper gaskets on the seats.

6.

Remove the nozzle heat seal. (Serial

No.:

48929

1

-)

3.

Remove

the

fuel over

P

low pipe.

Tightening torque

Nozzle

holder

Nozzle Heat Seal Service Removal Procedure

(Engine Serial Number

:

489291

and beyond)

IMPORTANT

0

Use a plus (Phillips head) screw driver that has

a

Dia. which

is

bigger than the heat seal hole.

(Approx.

6

mm)

114

in.

1.

Drive screw driver lightly into the heat seal hole.

2.

Turn screw driver three or four times each way.

3.

While turning the screw driver, slowly pull the

heat seal out together

with

the injection nozzle

gasket.

If

the heat seal drops, repeat the above procedure.

Heat

seal

and injection nozzle gasket must be

changed when the injection nozzle

is

removed for

cleaning or for service.

Rocker Arm and Push Rod

1.

Remove the rocker arm bracket mounting nuts

(1).

2.

Remove the rocker arm as a unit.

3.

Remove the push rods

(2).

0

After reassembling the rocker arm, be sure to

IMPORTANT

adjust the valve clearance.

:1:

cz?

9.81 to 1 1.28

Nsm

Rocker

Tightening torque

I

Hgcet

I

1

.OO

to 1

.I

5

kgfem

7.23 to 8.32 ft-lbs

NOTE

When putting the push rods

(2)

onto the tappets,

check to see

if

their

ends are properly engaged

with

the grooves.

S-63

Loading...

Loading...