S.4

FUELSYSTEM

68

mm

STROKE SERIES

WSM,OI

165

I

CO

19F030

I

[2]

INJECTION

PUMP

--

A1

16F

a

3083F065

---

ti:=

6:O

7:-

A078F001

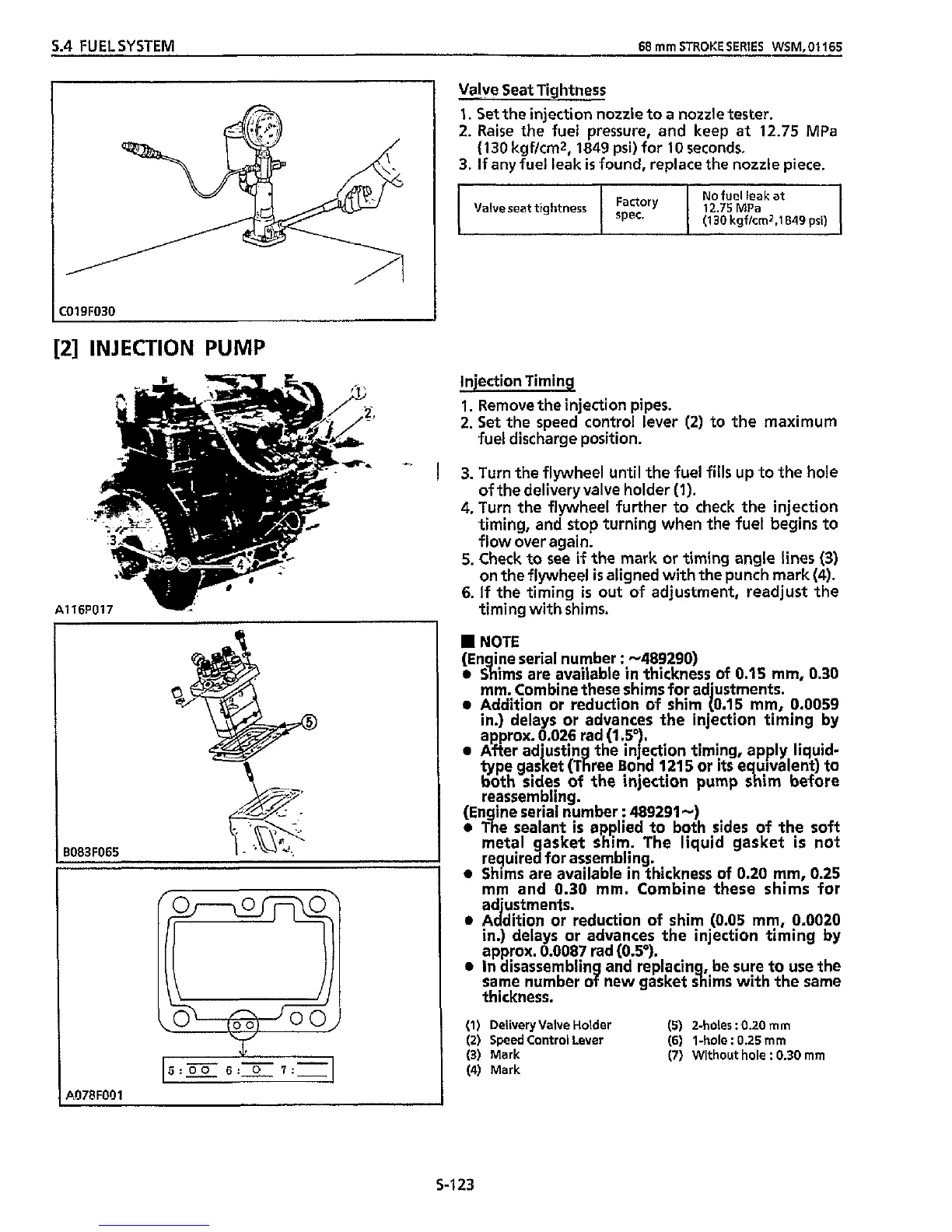

Valve

Seat

Tightness

1.

Set

the

injection nozzle to

a

nozzle

tester.

2.

Raise

the fuel pressure, and keep

at

12.75

MPa

(130 kgfkmz, 1849 psi) for

10

seconds.

3.

If

any fuel leak

is

found, replace the nozzle

piece.

Nofuel

leak

at

12.75

MPa

(130

kgf/crnZ,l849

psi)

Valve

seat

tightness

I

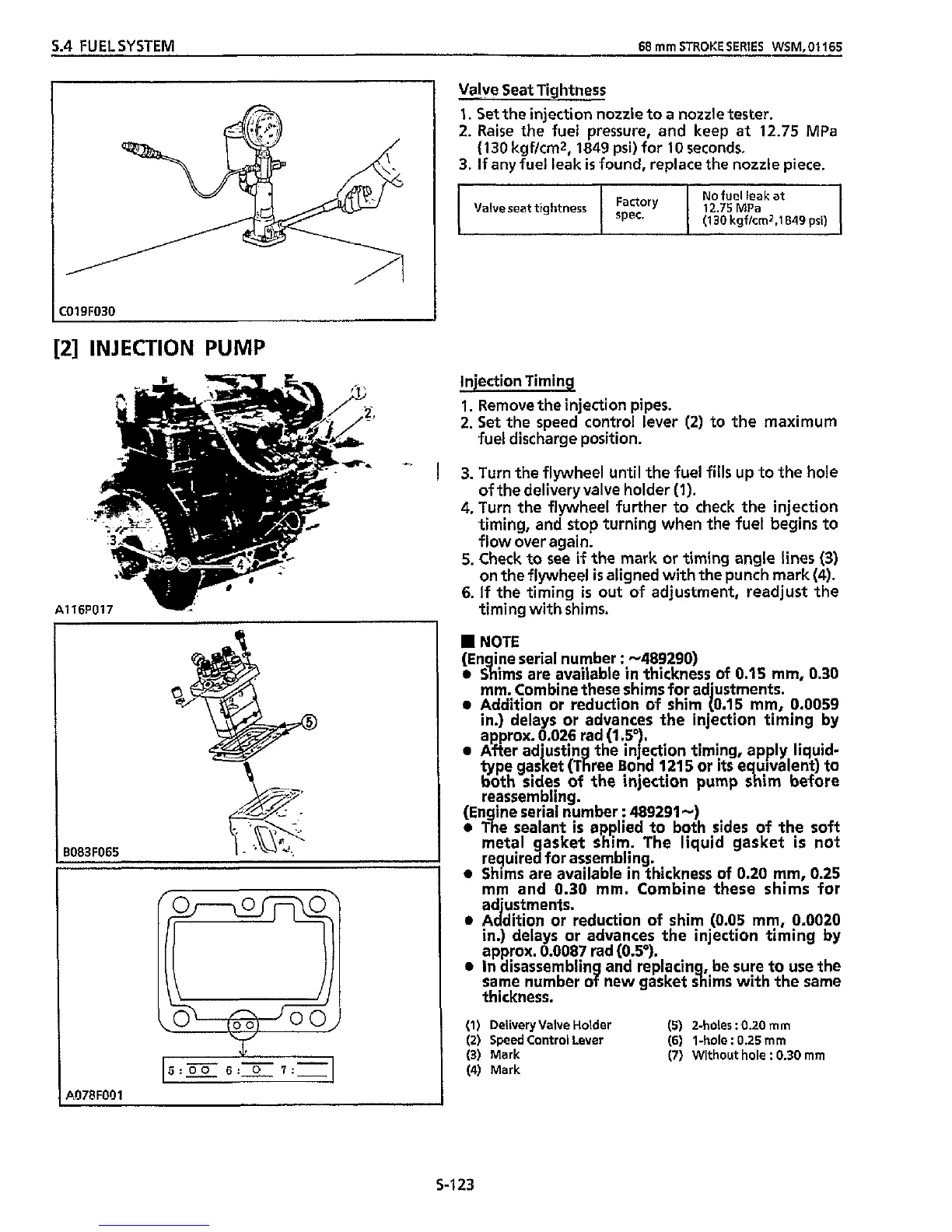

Injection Timing

1. Remove the injection pipes.

2.

Set

the speed control lever

(2)

to the maximum

fuel discharge position.

3.

Turn the flywheel until the fuel

fills

up to the hole

of the delivery

valve

holder

(1).

4.

Turn the flywheel further to check

the

injection

timing, and stop turning when the fuel begins to

flow over again.

5.

Check to see

if

the

mark or timing angle

lines

(3)

on the flywheel

is

aligned with the punch mark

(4).

6.

If

the timing

is

out of adjustment, readjust the

timing with shims.

NOTE

(En ine serial number

:

-489290)

0

S

a

ims

are

available

in

thickness of

0.15

mm,

0.30

mm. Combine these shimsfor ad’ustments.

0

Addition or reduction of shim

10.15

mm,

0.0059

in.) delays or advances the injection timing by

approx.

0.026

rad

(1.59.

0

After ad’ustin the injection timing, apply liquid-

both sides of the injection pump

s

im before

reassembling.

metal gasket shim. The liquid gasket

is

not

required for assembling.

0

Shims are available in thickness

of

0.20

mm,

0.25

mm and

0.30

mm. Combine these shims for

ad’ustments.

in.) delays or advances the injection timing by

approx.

0.0087

rad

(0.5’).

0

in disassemblin and replacin

be

sure to use the

thickness.

s,

type gas

((91

et

(T

ree Bond

1215

or

its

e

urvalent) to

e

T

a

e

sealant

is

applied to both sides of the soft

0

A

d

dition or reduction of shim

(0.05

mm,

0.0020

same number

o

0

new gasket 3ims with the same

(En ine serial number

:

489291~)

(1)

Delivery

Valve

Holder

(5)

2-holes

:

0.20

mm

(2)

Speed

Control

Lever

(6)

l-hole

:

0.25

mm

(3)

Mark (7)

Without

hole

:

0.30

mm

(4) Mark

S-123

Loading...

Loading...