5.4

FUEL

SYSTEM

68

mm

STROKE

SERIES

WSM,

01

160

Pressure falling time

A1

16P01

(1)

Speed Control Lever

:zybte

5

seconds

Delivery Valve Fuel Tightness

1.

Remove the injection pipes and injection nozzles.

2. Install the pressure tester (see page 5-55) to the

injection pump.

3. Set the speed control lever

(1)

to the maximum

fuel discharge position.

4.

Turn the flywheel counterclockwise to raise the

fuel pressure to 14.71 MPa (150 kgfkmz, 2133 psi).

5. Set the plunger

of

the injection pump at the

bottom dead center to reduce the delivery

chamber pressure to zero.

6.

Measure the falling time of the fuel pressure from

14.71 to 13.73 MPa (from 150 to 140 kgfkmz, from

2133 to 1991

psi).

7.

If

the measurement

is

less than the allowable limit,

replace the delivery valve or injection pump

assembly.

Fuel overflow pipe

nut

~~~~~z&!$~

14.5 to

18.1

ft-lbs

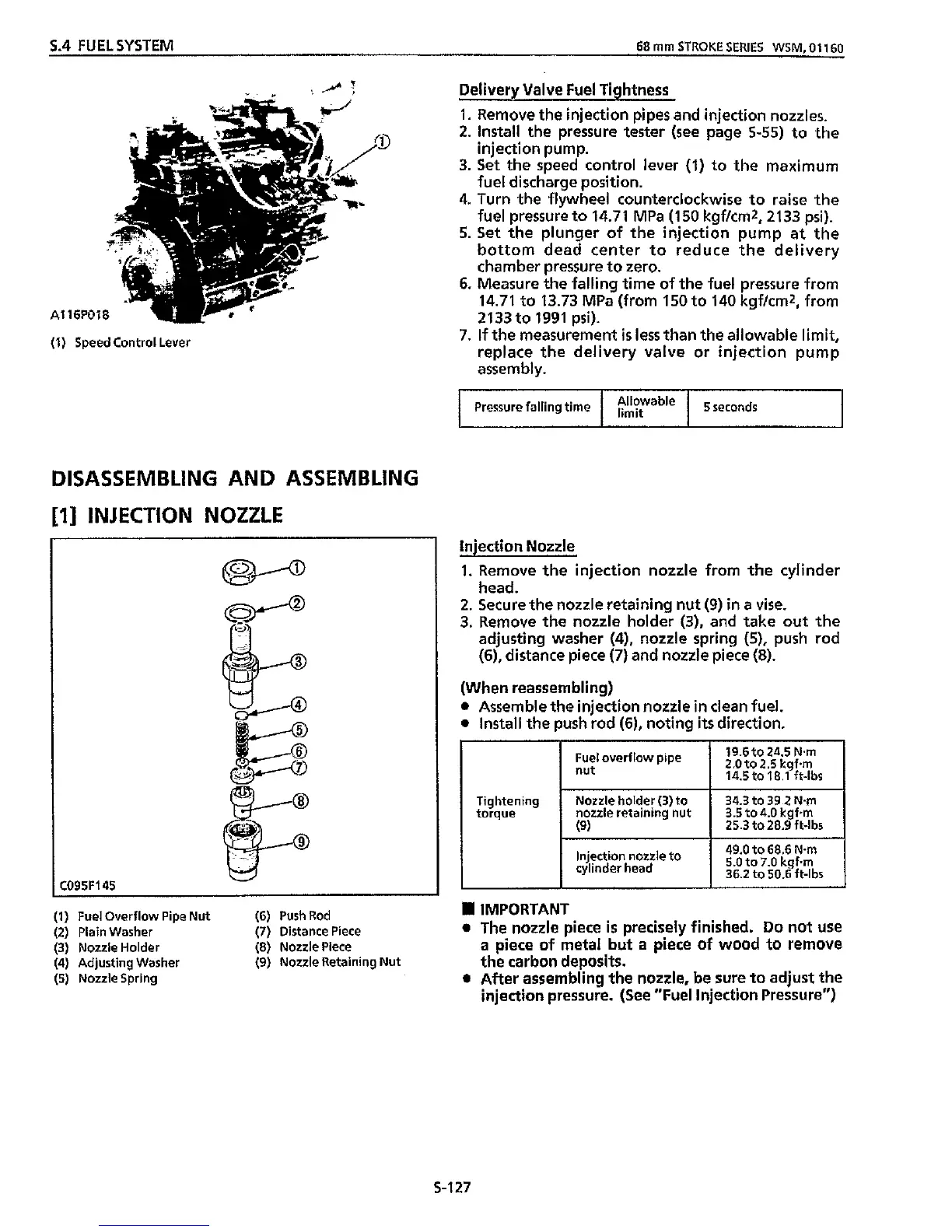

DISASSEMBLING AND ASSEMBLING

[I]

INJECTION NOZZLE

Nozzle holder

(3)

to

nozzle retaining nut

(9)

C095F

34.3 to

39.2

Nm

3.5 to

4.0

kgfm

25.3

to

28.9

ft-lbs

45

(1)

Fuel Overflow Pipe Nut

(6)

PushRod

(2) Plain Washer

(7)

Distance Piece

(3) Nozzle Holder

(4)

Adjusting Washer

(5) Nozzle Spring

(8)

Nozzle Piece

(9)

Nozzle Retaining Nut

Injection Nozzle

1. Remove the injection nozzle from the cylinder

2. Secure the nozzle retaining nut (9)

in

a vise.

3.

Remove the nozzle holder (3), and take out the

adjusting washer

(4),

nozzle spring (5),

push

rod

(6), distance piece

(7)

and nozzle piece

(8).

(When reassembling)

0

Assemble the injection nozzle

in

clean fuel.

0

Install the push rod

(6),

noting

its

direction.

head.

Tightening

torque

49.0

to

68.6

Nm

5.0

to

7.0

kgf.,,,

Injection nozzle to

cylinder head

I

36.2 to 50.6 ft-lbs

IMPORTANT

0

The nozzle piece

is

precisely

finished.

Do

not use

a

piece

of

metal

but

a

piece

of

wood to remove

the carbon deposits.

0

After assembling the nozzle, be sure to adjust the

injection pressure. (See "Fuel Injection Pressure")

S-127

Loading...

Loading...