5.3

COOLING

SYSTEM

68

mm

STROKE

SERIES

WSM,

01

160

Factory

Fan belt tension

(Deflection

A)

spec.

IEl

COOLING

SYSTEM

Approx.

10

mml10 kgf

Approx.

0.39

in./lO kgf

(22.1

Ibs)

CHECKING AND ADJUSTING

[I]

FAN

BELT

Radiator leakage

test pressure spec.

Fan

Belt

Tension

157 kPa

1.6

kgf/cm*

23

psi

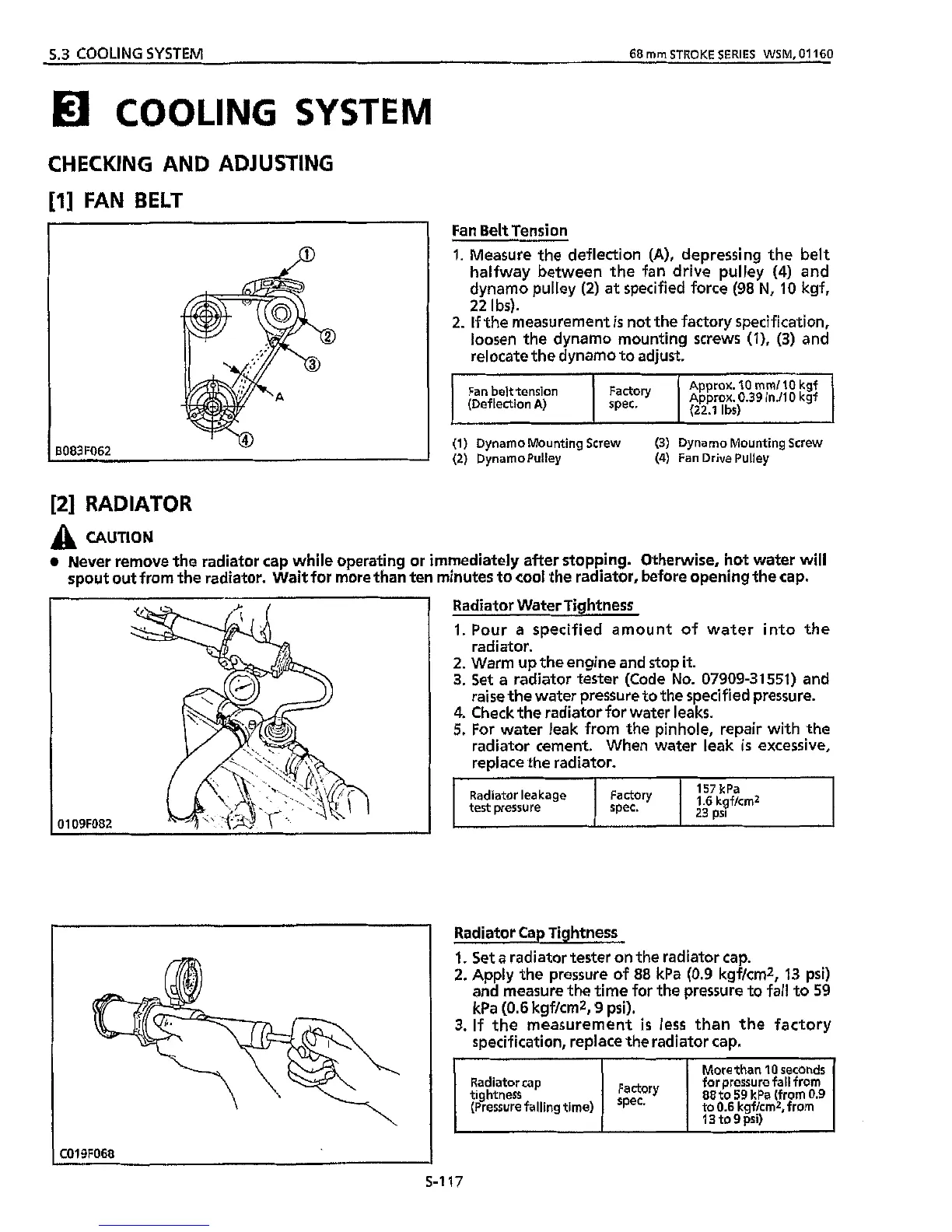

Radiator Cap Tightness

1.

Set

a

radiator tester on the radiator cap.

2.

Apply the pressure

of

88

kPa

(0.9

kgfkmz,

13

psi)

and measure the time for the pressure to

fall

to

59

kPa

(0.6

kgfkmz,

9

psi).

3.

If

the measurement

is

less

than the factory

specification, replace the radiator cap.

More than

10

seconds

1

Radiator cap for pressure fall from

88

to

59 kPa from 0.9

to

0.6

kgf/cm ,from

13to9psi)

tightness spec.

(Pressure falling time)

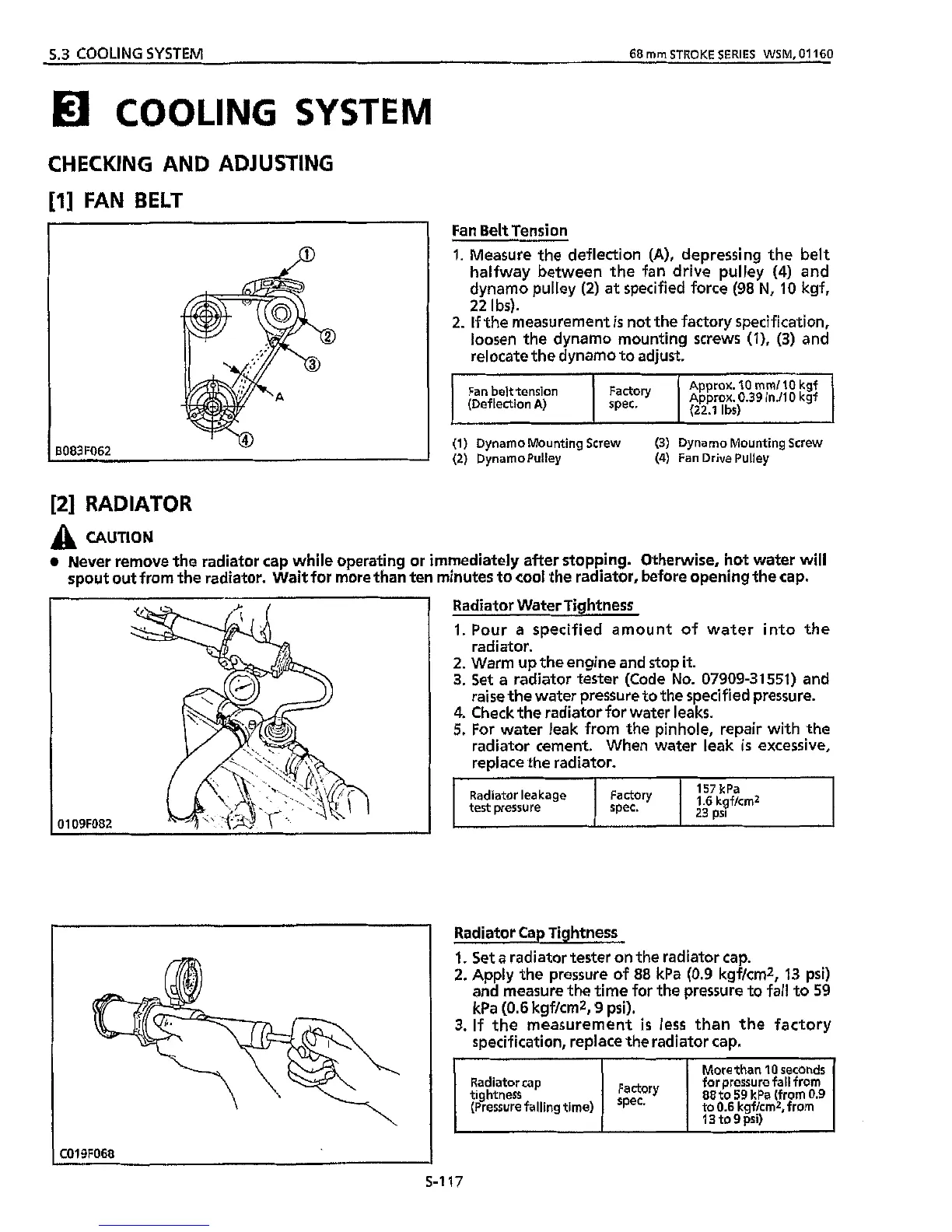

1.

Measure the deflection

(A),

depressing the belt

halfway between the fan drive pulley

(4)

and

dynamo pulley

(2)

at

specified force

(98

N,

10

kgf,

22

I

bs).

2.

If

the

measurement

is

not the factory specification,

loosen the dynamo mounting screws

(l),

(3)

and

relocate the dynamo to adjust.

(1) Dynamo Mounting Screw

(2)

Dynamo Pulley

(3)

Dynamo Mounting Screw

(4)

Fan Drive Pulley

Never remove the radiator cap while operating or immediately after stopping. Otherwise, hot water

will

spout out from the radiator. Wait for more than ten minutes to cool the radiator, before opening the cap.

Radiator Water Tightness

1.

Pour

a

specified amount of water into the

radiator.

2.

Warm up

the

engine and stop

it.

3.

Set

a

radiator tester (Code

No.

07909-31551)

and

raise

the

water pressure to

the

specified pressure.

4.

Check the radiator for water leaks.

5.

For water leak from the pinhole, repair with the

radiator cement. When water leak

is

excessive,

replace the radiator.

I

I

I

I

CO1

OF068

I

S-117

Loading...

Loading...