5.1 ENGINE

BODY

68

mm

STROKE SERIES

WSM, 01 160

Oil clearance

between crank pin

and crank pin

bearing

L

CO

19 F06 1

B

Factory 0.019to0.081

mm

Allowable 0.15

mm

limit 0.0059 in.

0.00075 to 0.00319 in.

,

spec*

I0071F005

Factory

Crank pin

O.D.

spec.

Al

I

33.959 to33.975

mm

1.33697 to 1.33759 in.

Oil Clearance between Crank

Pin

and Crank

Pin

Bearina

0.2

mrn

0.008 in.

0.4

mm

0.016 in.

1.

Clean ,the

crank

in

and crank

in

bearing.

2.

Put a strip of p

P

astigage

(Co

8

e No. 07909-30241)

on the center of the crank pin.

IMPORTANT

0

Never insert the press gauge into the crank pin oil

hole.

3. install the connecting rod cap and tighten the

connecting rod screws to the specified torque

(26.5

to 30.4 N-m, 2.7 to

3.1

kgf.m, 19.5 to 22.4

ft-

Ibs), and remove the cap again.

NOTE

0

Be sure not to move the crankshaft while the

connecting rod screws are tightened.

4.

Measure the amount of the flattening

with

the

scale, and get the

oil

clearance.

5.

If

the

oil

clearance exceeds the allowable limit,

replace the crank

pin

bearing.

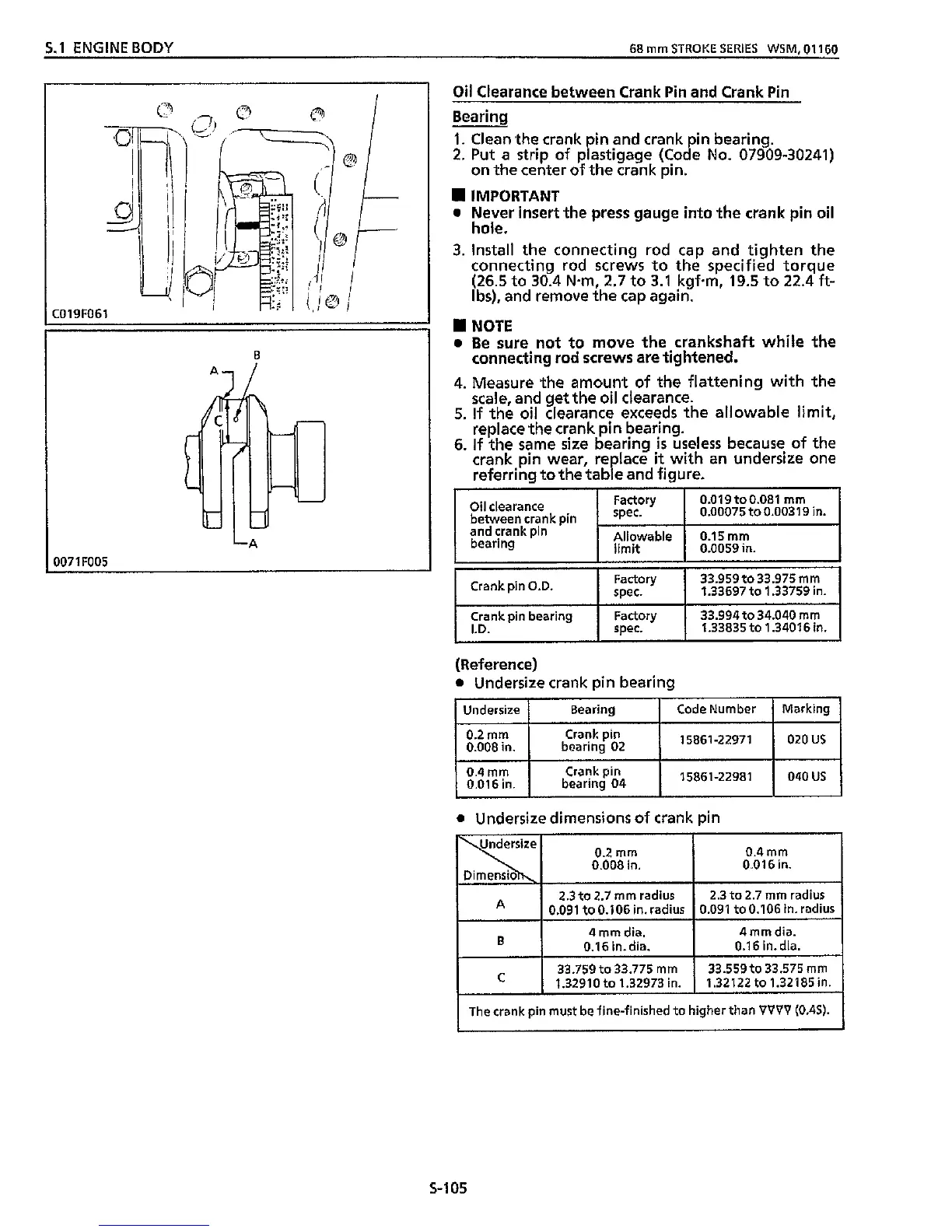

6.

If

the same size bearing

is

useless because

of

the

crank

pin

wear, re lace

it

with

an undersize one

referring

to

the tab

P

e and figure.

I

1

15861-22971

020US

Crank pin

bearing 02

Crank pin

bearing

04

15861-22981

040

US

0.2

mm

0.008 in.

0.4

mm

0.01 6 in.

I

I

33.994 to 34.040

mm

1.33835 to 1.3401 6 in.

I

Crank pin bearing

I.D.

A

B

(Reference)

0

Undersize crank

pin

bearing

Undersize Bearing Code Number Marking

2.3 to 2.7

mm

radius

0.091 to0.106 in. radius

4

mm

dia.

0.16 in. dia.

2.3

to 2.7

mm

radius

0.091 to0.106 in. radius

4

mm

dia.

0.1

6 in. dia.

~~

33.759 to 33.775

mm

1.32910to 1.32973 in.

C

0

Undersize dimensions

of

crank pin

33.559 to 33.575

mm

1.32122

to

1.32185 in.

5-1

05

Loading...

Loading...