5.4

FUELSYSTEM

68

mm

STROKE

SERIES

WSM,

01 161

Pump element fuel

tightness (Fuel pressure)

AI

r

Allowabie

limit

2133 psi

(1)

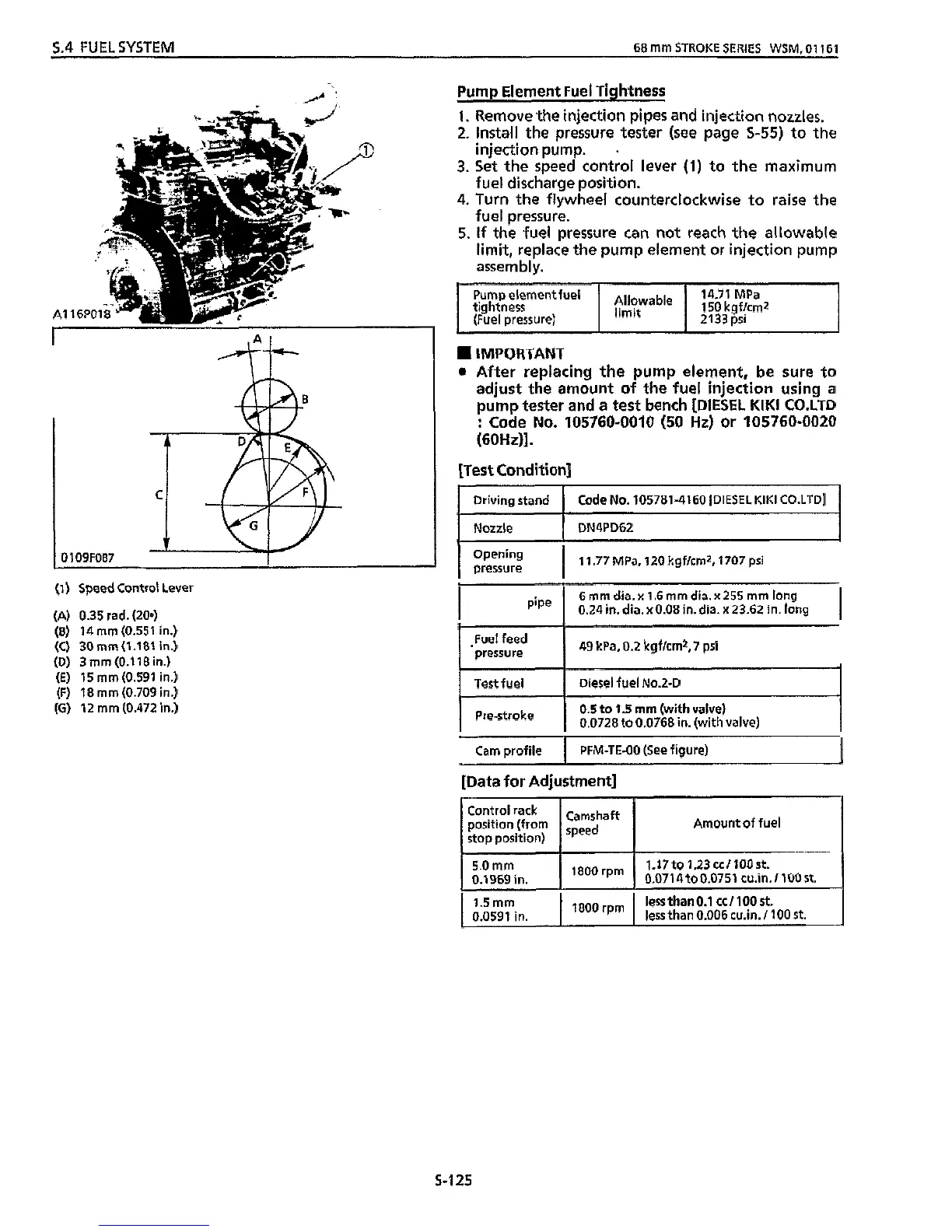

Speed Control Lever

(A) 0.35 rad. (200)

(6)

14

mm

(0.551

in.)

(C)

30mm(1.181

in.)

(D) 3

mm

(0.1

18 in.)

(E)

15

mm

(0.591 in.)

(F)

18

mm

(0.709 in.)

(G)

12

mm

(0.472

in.)

~

Driving stand

Nozzle DN4PD62

Code

No.

105781-4160 [DIESEL

KIM1

CO.LTD]

I

Pump Element Fuel Tightness

~~~

Cam profile

1.

Remove the injection

pipes

and injection nozzles.

2.

Install the pressure tester (see page

S-55)

to

the

injection pump.

.

3.

Set the speed control lever

(1)

to the maximum

fuel discharge position.

4.

Turn the flywheel counterclockwise

to

raise

the

fuel pressure.

5.

If

the fuel pressure can

not

reach the allowable

limit, replace the pump element or injection pump

assembly.

~

PFM-TE-OO (See figure)

I

5.0

mm

0.1969

in.

IMPORTANT

0

After replacing the pump element, be sure to

adjust

the

amount

of

the fuel injection using a

pump tester and

a

test bench

[DIESEL

KlKl

CO.LTD

:

Code

No.

105760-0010

(50

Ht)

or

105760-0020

(60Hz)I.

[Test Condition]

1

.I7 to 1.23 cc/IOo

st.

'*O0

rpm

0.0714to0.0751 cu.in.ll00st.

Opening

I

pressure

I

11.77 MPa,

120

kgf/crn2, 1707

Psi

I

6

mm dia.

x

I

.6

rnm

dia.

x

255

mm

long

I

0.24

in.

dia. x0.08 in. dia.

x

23.62 in. long

49 kPa,

0.2

kgf/cmz,

7

psi

I

Fuel feed

pressure

I

Test fuel Diesel fuel No.2-D

I

I

0.5 to 1.5

mm

(with valve)

1

I

0.0728 to 0.0768 in. (with valve)

[Data for Adjustment]

Control rack

Camshaft

1-

position (from

I

speed

I

stop position)

Amountoffuel

lessthanO.l cc/100st.

1.5

mm

0.0591 in.

I

"O0

rpm

I

less

than 0.006 cu.in./ 100

st.

5-125

Loading...

Loading...