M.4

FUEL

SYSTEM

68

mm STROKE SERIES

WSM,

01

160

(1)

Pump

Element

I

1001

1F043

(2)

Delivery Valve

I

001

1

F042

(3)

Dumping

Valve

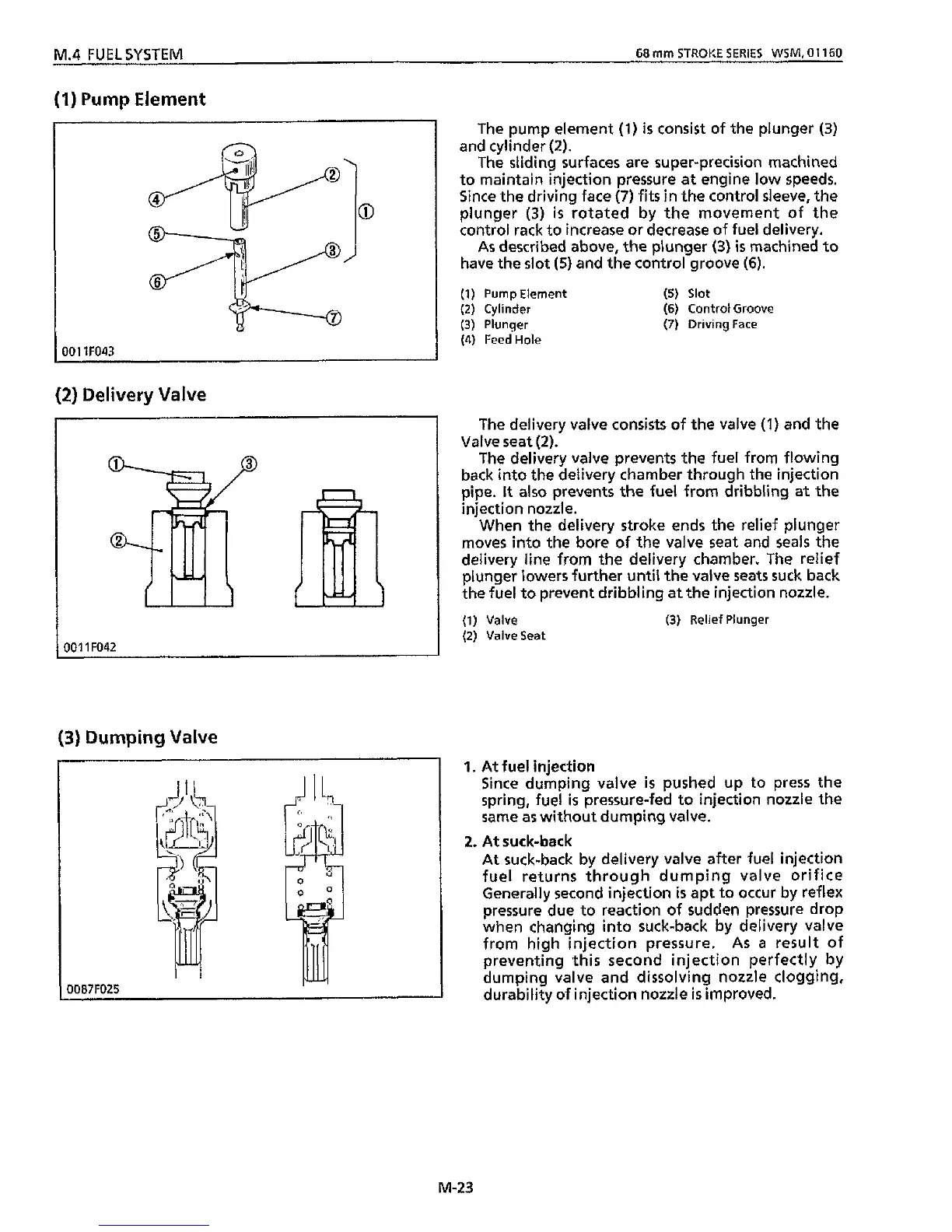

The pump element

(1)

is

consist of

the

plunger (3)

and cylinder

(2).

The

sliding

surfaces are super-precision machined

to maintain injection pressure at engine

low

speeds.

Since the driving face

(7)

fits

in

the control sleeve, the

plunger

(3)

is

rotated by the movement of the

control rack to increase or decrease of fuel delivery.

As

described above, the plunger

(3)

is

machined

to

have the slot

(5)

and the control groove

(6).

(2)

Cylinder

(6)

Control Groove

(3)

Plunger

(7)

Driving

Face

(4)

Feed

Hole

(1)

Pump Element

(5)

Slot

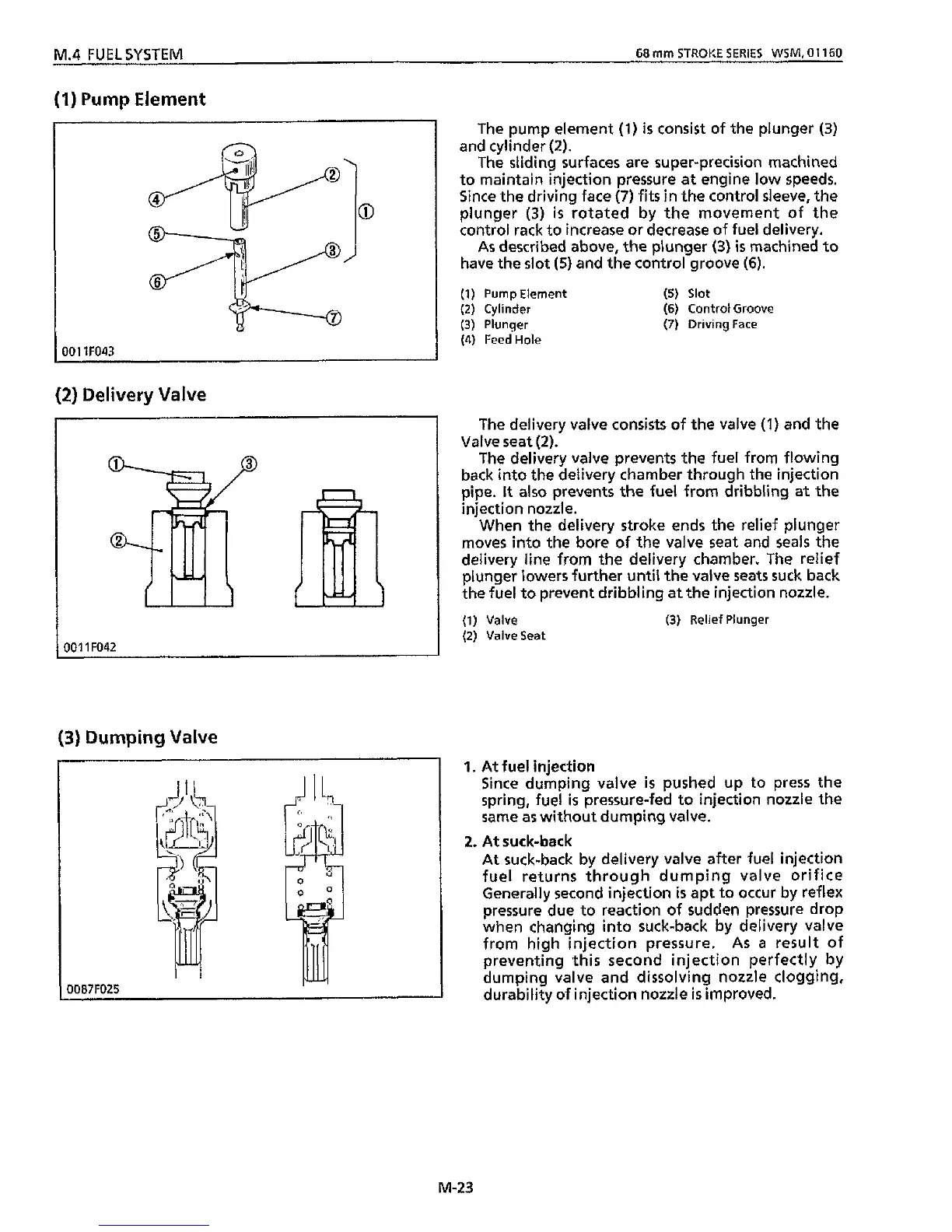

The delivery valve consists of the valve

(1)

and the

Valve seat

(2).

The delivery valve prevents the fuel from flowing

back into the delivery chamber through

the

injection

pipe.

it

also prevents the fuel from dribbling at the

injection nozzle.

When the delivery stroke ends the relief plunger

moves into

the

bore

of

the valve seat and seals the

delivery line from the delivery chamber. The relief

plunger lowers further

until

the valve seats suck back

the fuel to prevent dribbling at the injection nozzle.

(1)

Valve

(3)

Relief Plunger

(2)

Valve

Seat

1.

At

fuel injection

Since dumping valve

is

pushed

up

to press the

spring, fuel

is

pressure-fed to injection nozzle the

same

as

without dumping valve.

At suck-back by delivery valve after fuel injection

fuel returns through dumping valve orifice

Generally second injection

is

apt to occur by reflex

pressure due to reaction of sudden pressure drop

when changing into suck-back by delivery valve

from high injection pressure.

As

a

result of

preventing

this

second injection perfectly by

dumping valve and dissolving nozzle clogging,

durability of injection nozzle

is

improved.

2.

At

suck-back

M-23

Loading...

Loading...