M.4 FUELSYSTEM

68

mm

STROKE

SERIES

WSM,

01

160

(4)

Operation

of

Pump Element

3

DO

1

1

F044

2

4

(5)

injection Control

@

,!

@

0

109F304

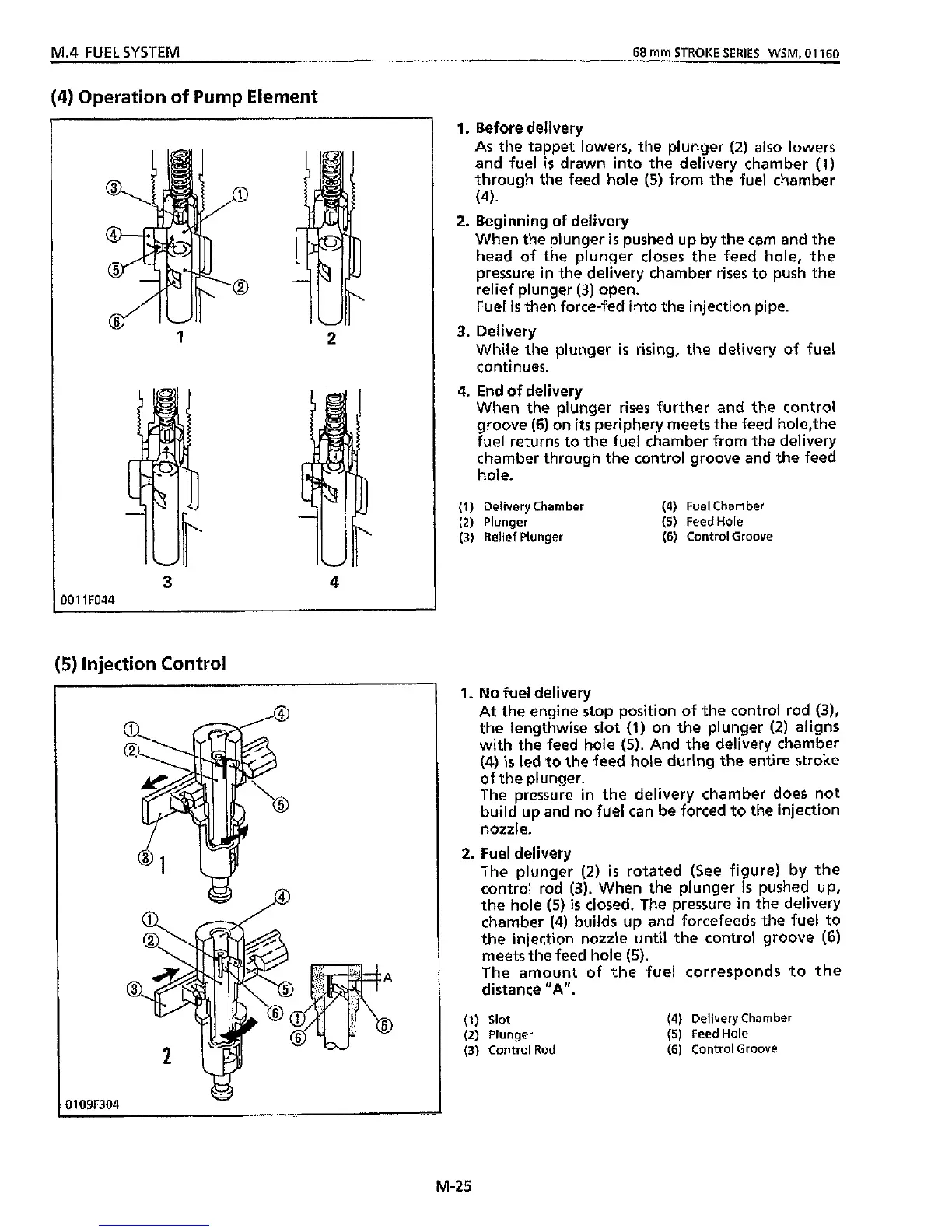

1.

Before delivery

As

the

tappet lowers,

the

plunger

(2)

also

lowers

and fuel

is

drawn into the delivery chamber

(1)

through the feed hole

(5)

from the fuel chamber

(4)

When

the

plunger

is

pushed up by the cam and the

head of the plunger closes the feed hole, the

pressure in the delivery chamber rises to push the

relief plunger

(3)

open.

Fuel

is

then

force-fed into the injection pipe.

While the plunger

is

rising, the delivery of fuel

con

ti

nues.

When the plunger rises further and the control

groove

(6)

on

its

periphery meets the feed hole,the

fuel returns to the fuel chamber from the delivery

chamber through the control groove and the feed

hole.

2.

Beginning of delivery

3.

Delivery

4.

End of delivery

(1)

Delivery Chamber

(4)

Fuel Chamber

(2)

Plunger

(5)

FeedHole

(3)

Relief Plunger

(6)

Control Groove

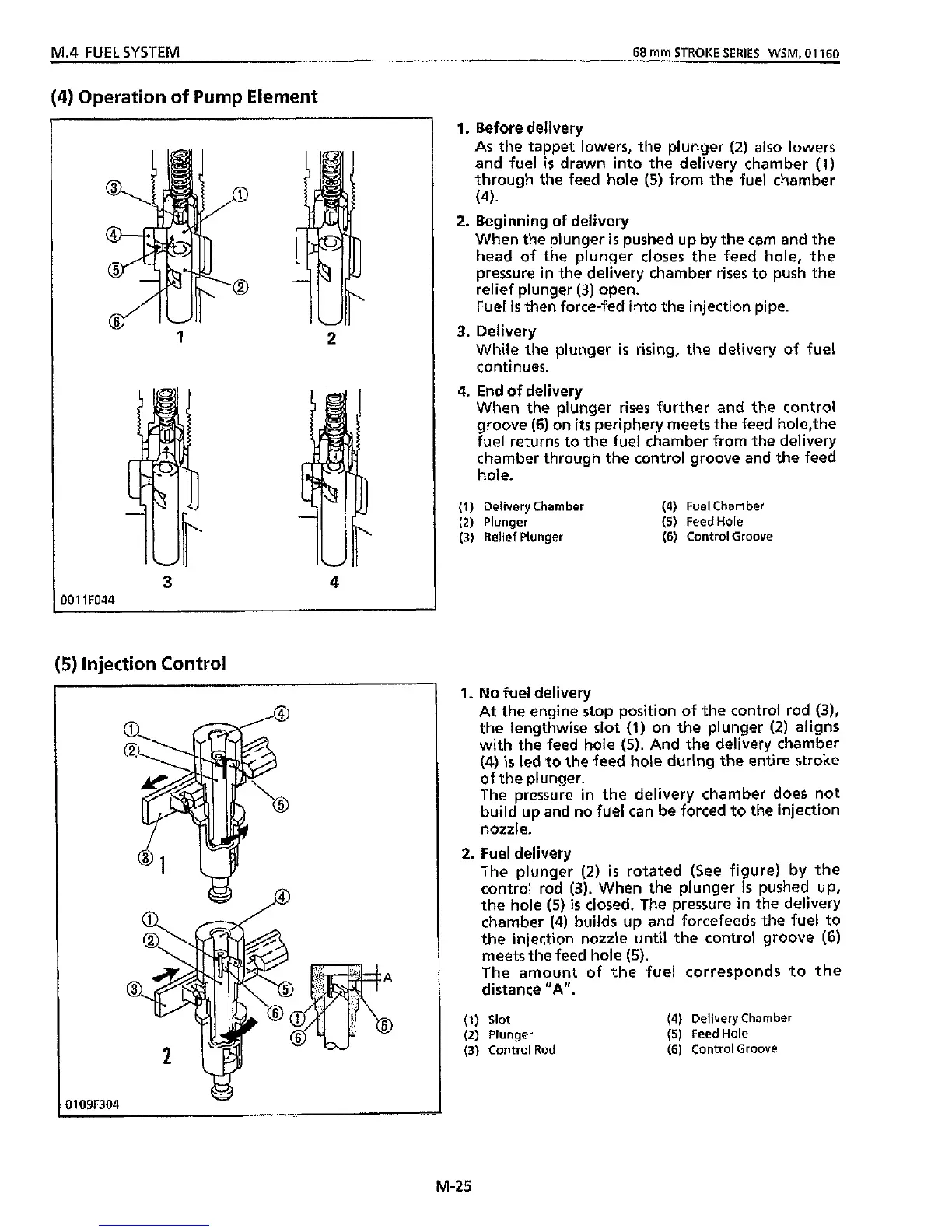

1.

No

fuel delivery

At the engine stop position

of

the control rod

(3),

the lengthwise slot

(1)

on the plunger

(2)

aligns

with

the feed hole

(5).

And the delivery chamber

(4)

is

led

to

the feed hole

during

the entire stroke

of

the plunger.

The pressure

in

the delivery chamber does not

build

up and no fuel can be forced to

the

injection

nozzle.

The plunger

(2)

is

rotated (See figure) by the

control rod

(3).

When the plunger

is

pushed up,

the hole

(5)

is

closed. The pressure in the delivery

chamber

(4)

builds up and forcefeeds

the

fuel to

the injection nozzle

until

the control groove

(6)

meets

the

feed hole

(5).

The amount of the fuel corresponds to the

distance

"A".

2.

Fuel delivery

(1)

Slot

(2)

Plunger

(3)

Control Rod

(4)

Delivery Chamber

(5)

FeedHole

(6)

Control Groove

M-25

Loading...

Loading...