Power harrow

40

HR6004DR

Putting into service

- Clean and reassemble the unit.

- Tightening torque: 10 daN m (74 lbf ft).

- Proceed the same way on the other gearbox.

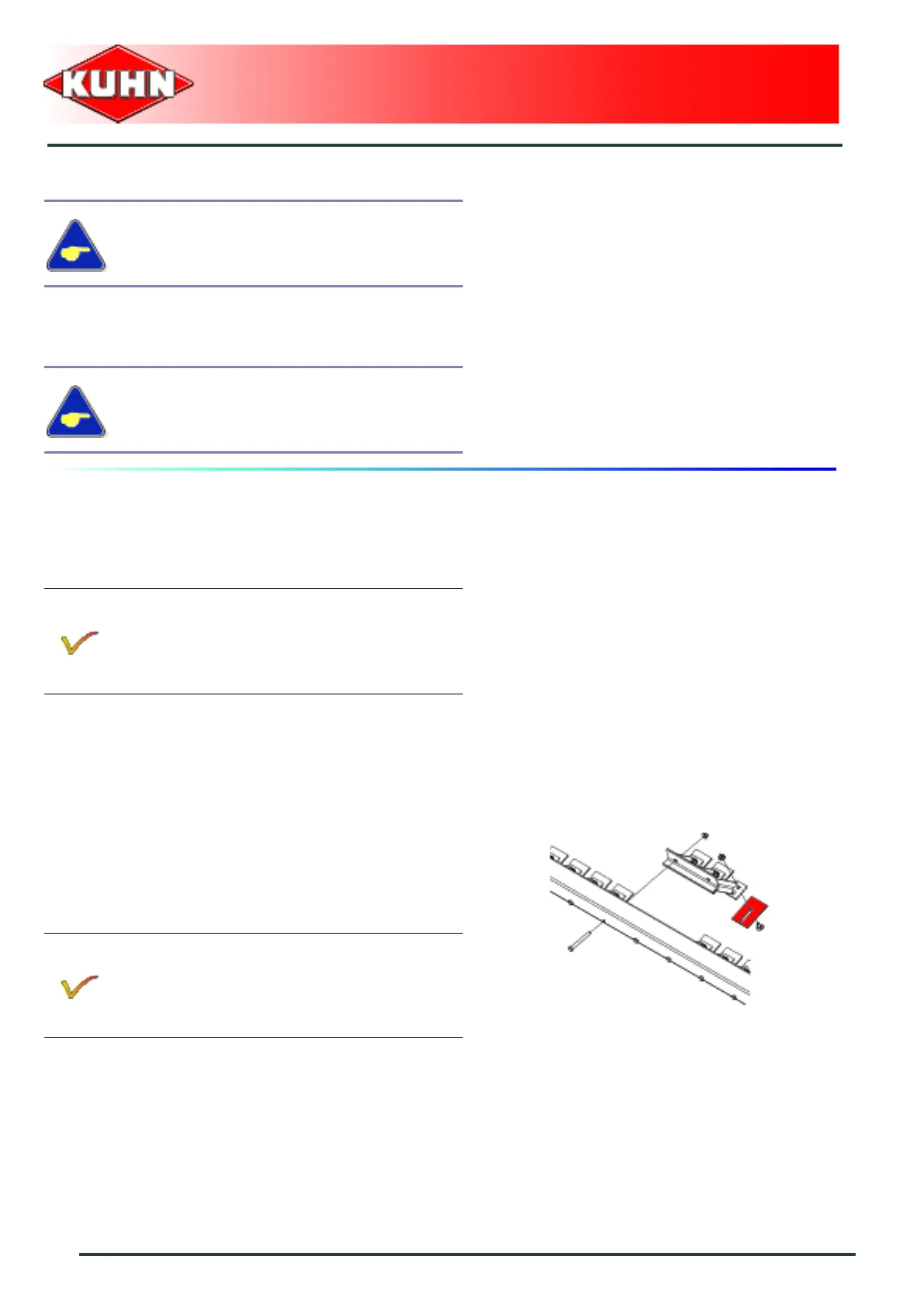

Adjusting the roller scrapers

Standard plate

The scraper plates are factory preset on a reference

roller.

When the machine is attached, check that the roller can

rotate freely.

Adjusting the plates:

• Loosen plate attachment nut.

• Adjust plate to bring it closer to the roller. Check that

roll and scraper do not contact by rotating the roller.

• Tigthen nut. Torque nut to: 8 daN m (59 lbf ft).

• Ensure the plates are fitted central to the stud rows.

• The slots in the scraper plate supports provide

lateral adjustment: Tightening torque: 10 daN m

(67 lbf ft).

Check O-ring is correctly positioned within

gearbox cover.

The rotor speed must be the same for both

half-harrows.

The scraper bar is factory fitted with:

- Packer PK2 roller: Non coated plates (Part

no. 52532130).

- Maxipacker roller: Hard coated plates (Part

no. 52593410).

Maxipacker roller:

Note the scraper plate mounting direction:

ensure that the hard coating is towards the front

and faces down: Ensure that the scraper hard

coating is towards the front and faces down.

Loading...

Loading...